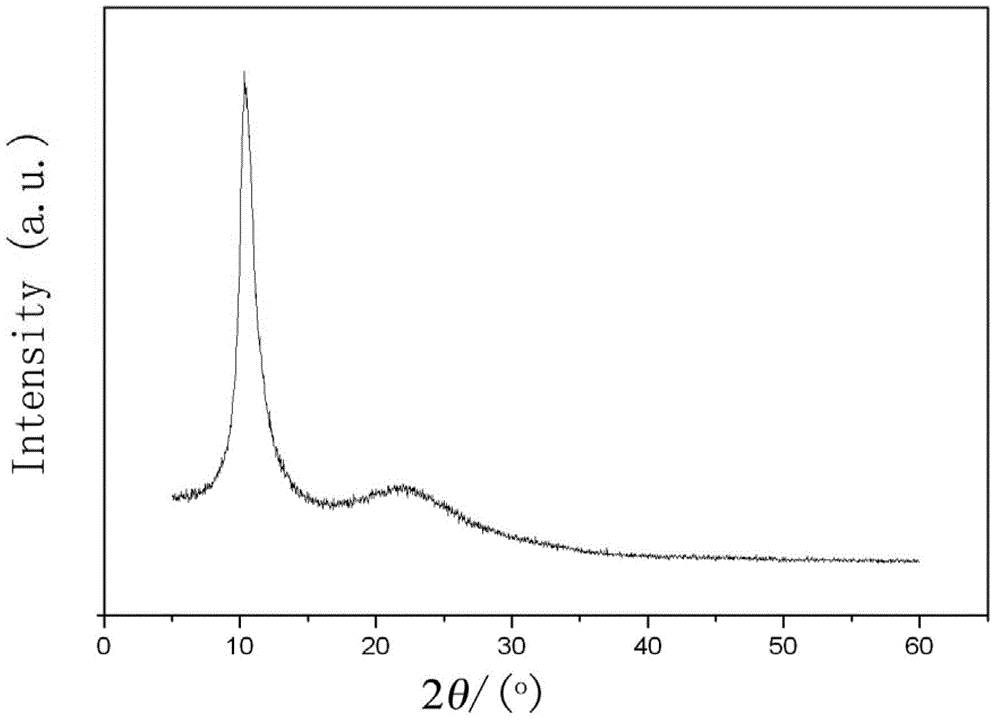

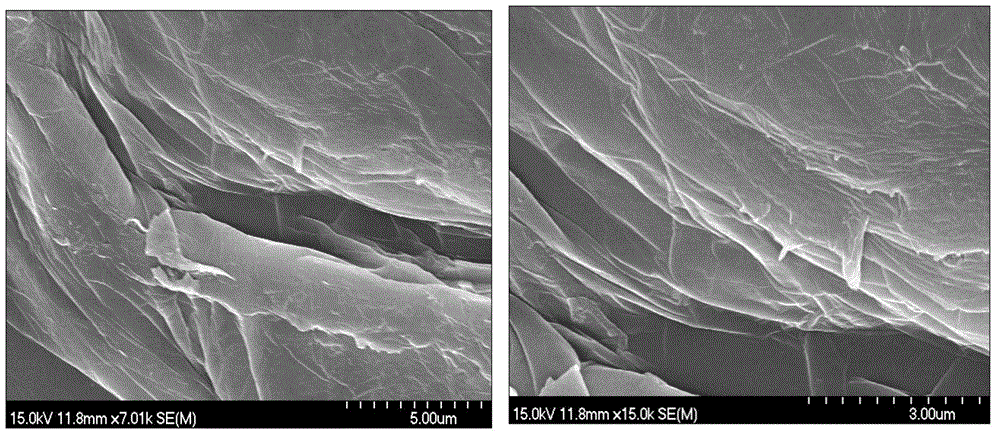

Method of preparing dibenzyl ether from benzyl alcohol under catalysis of graphene oxide

A technology of graphene catalyzing benzyl alcohol and dibenzyl ether, which is applied in the directions of dehydration of hydroxyl-containing compounds to prepare ether, chemical instruments and methods, catalysts for physical/chemical processes, etc. problem, to achieve the effect of high selectivity, environmental friendliness and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Mix 0.5g of graphene oxide and 5g of benzyl alcohol in a 50ml three-necked flask, stir while heating, keep the temperature at about 90°C, and react for 24h. The reacted product was filtered under reduced pressure, and the filtrate was collected, which was a mixture of dibenzyl ether. Then the collected mixture containing dibenzyl ether was treated with CH 2 Cl 2 Diluted, and measured by Fuli GC9790 gas chromatography, the conversion rate of benzyl alcohol was 64.5%, and the selectivity of dibenzyl ether was 86.5%.

Embodiment 2

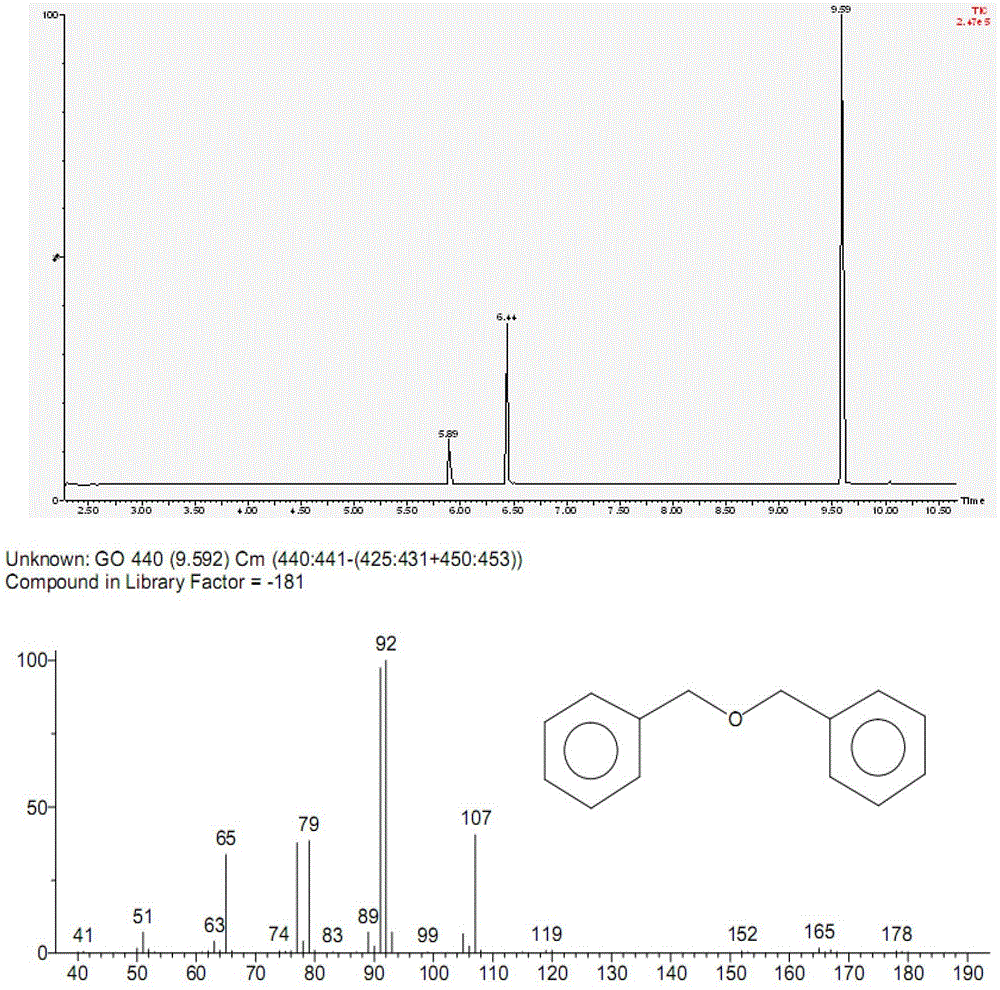

[0028] Mix 0.3g of graphene oxide and 6g of benzyl alcohol in a 50ml three-necked flask, stir while heating, keep the temperature at about 90°C, and react for 24h. The product after the reaction was suction filtered under reduced pressure, and the filtrate was collected, which was a mixture of dibenzyl ether. A 6 μL mixed sample was extracted with a gas chromatographic injection needle and the conversion rate of benzyl alcohol was 84.6% as measured by Fuli GC9790 gas chromatography. Dibenzyl ether The selectivity of ether is 84.8%, and the GC-MS test chart is attached figure 2 . Then the dibenzyl ether mixture was distilled at 220-240°C under normal pressure for 1 hour to obtain the remaining liquid which was dibenzyl ether, with a yield of 3.9 g and a yield of 70.9%.

Embodiment 3

[0030] Mix 0.3g of graphene oxide and 18g of benzyl alcohol in a 50ml three-necked flask, stir while heating, keep the temperature at about 90°C, and react for 24h. The reacted product was filtered under reduced pressure, and the filtrate was collected, which was a mixture of dibenzyl ether. Then the collected mixture containing dibenzyl ether was treated with CH 2 Cl 2 Diluted, and measured by Fuli GC9790 gas chromatography, the conversion rate of benzyl alcohol was 39.2%, and the selectivity of dibenzyl ether was 88.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com