Method for improving sulfonation process of naphthalene-based water reducer

A naphthalene-based water reducer and sulfonation technology, which is applied in the field of improving the sulfonation process of naphthalene-based water reducers, can solve the problems of low sulfonation rate, waste of energy, and waste, so as to increase the degree of sulfonation and reduce production costs , the effect of reducing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

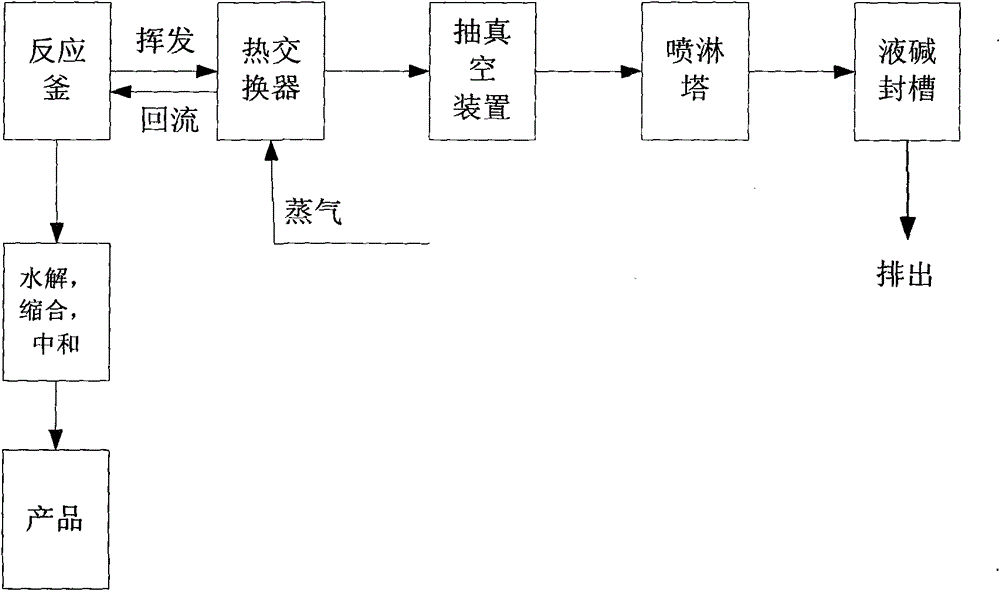

Embodiment 1

[0013] Measure 1.2 tons of industrial naphthalene into the reactor, heat up to 120°C, start to add 1.3 tons of 98% concentrated sulfuric acid dropwise, and finish the dropwise addition in half an hour. Start the negative pressure device every 0.5h, control the pressure in the kettle to 0.07MP, and the extraction time is 8 minutes. At the same time, turn on the steam valve of the heat exchanger to melt the volatilized industrial naphthalene, ensure the smooth flow of gas in the whole extraction device, and extract the reaction kettle. The gas is treated with more than two alkali sprays in the spray tower, then enters the liquid alkali sealing tank for neutralization treatment, and is finally discharged. After the sulfonation is completed, the dry powder product is obtained by hydrolysis, condensation and neutralization, and the sulfonation rate is 95.50%.

Embodiment 2

[0015] Measure 1.2 tons of industrial naphthalene into the reactor, heat up to 120°C, start to add 1.3 tons of 98% concentrated sulfuric acid dropwise, and finish the dropwise addition in half an hour. Start the negative pressure device every 0.5 hours, control the pressure in the kettle to 0.08 MP, and the extraction time is 6 minutes. At the same time, start the steam valve of the heat exchanger to melt the volatilized industrial naphthalene, so as to ensure the smooth flow of gas in the entire extraction device. After the sulfonation is completed, the dry powder product is obtained by hydrolysis, condensation and neutralization, and the detected sulfonation rate is 96.20%.

Embodiment 3

[0017] Measure 1.2 tons of industrial naphthalene into the reactor, heat up to 120°C, start to add 1.3 tons of 98% concentrated sulfuric acid dropwise, and finish the dropwise addition in half an hour. Start the negative pressure device every 0.5 hours, control the pressure in the kettle to 0.09 MP, and the extraction time is 5 minutes. At the same time, start the steam valve of the heat exchanger to melt the volatilized industrial naphthalene, so as to ensure the smooth flow of gas in the entire extraction device. After the sulfonation is completed, the dry powder product is obtained by hydrolysis, condensation and neutralization, and the sulfonation rate is 96.50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com