Method for preparing ethylene and propylene through catalytic cracking of light hydrocarbons

A technology for catalytic cracking and light hydrocarbons, applied in catalytic cracking, hydrocarbon cracking, hydrocarbon production, cracking, etc., can solve the problems of low yields of ethylene and propylene, difficulty in high-temperature cracking of light hydrocarbons, etc., and achieve good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

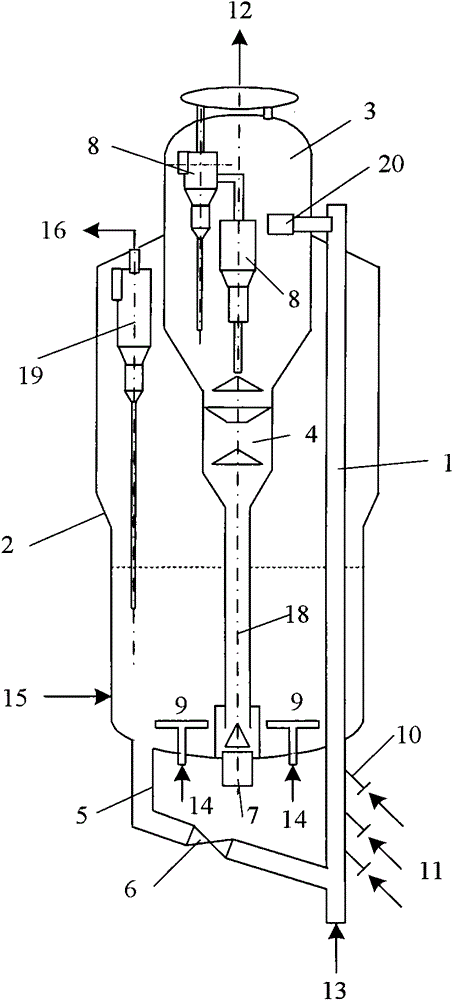

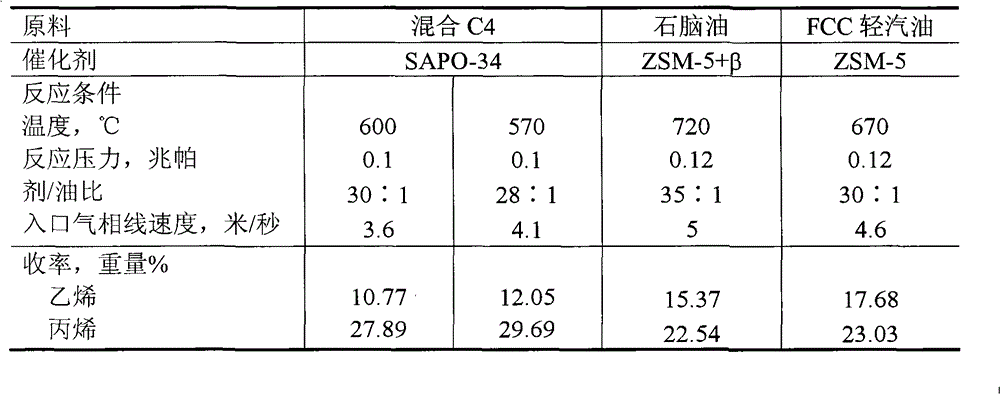

[0029] exist figure 1 On the shown device, 4 groups of experiments were carried out, and the reaction raw materials, catalysts, reaction conditions and results are shown in Table 1.

[0030] The content of butene in the mixed C4 is 73.8% by weight, and the content of n-butane is 26.2% by weight; the naphtha is mainly C 5 ~C 8 Alkanes, the contents are respectively 12.62 wt%, 25.54 wt%, 25.25 wt%, 17.86 wt%; catalytic cracking light gasoline (FCC light gasoline) is mainly pentene and hexene, the contents are respectively 36.4 wt% and 34.1 wt%.

[0031] The catalyst used in the experiment was prepared by a semi-synthetic method, that is, the molecular sieve, the carrier and the binder were mechanically mixed, and an appropriate amount of water, HCl and H 3 PO 4 (Not added when preparing SAPO-34 catalyst), control the pH value to not less than 3, stir the slurry evenly and spray it at 500°C. In the ZSM-5 catalyst used, the mass ratio of HZSM-5 molecular sieve and matrix is ...

Embodiment 2

[0039] Adopt the built-in type riser device basically identical with embodiment 1, but two feed nozzles are set on the built-in riser, two nozzles are 0.3 meters apart, enter and mix C4 and FCC light gasoline respectively from bottom to top, reaction raw material , reaction conditions, catalyst and reaction results are shown in Table 3. The composition of the raw materials used and the preparation process of the catalyst are shown in Example 1.

[0040] table 3

[0041]

Embodiment 3~7

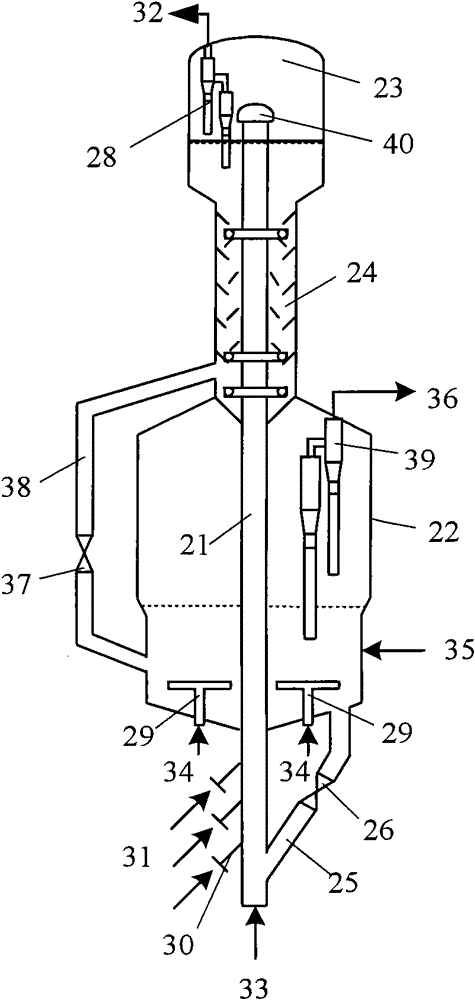

[0043] exist figure 2 Five groups of experiments were carried out on the shown device, and the reaction raw materials, reaction conditions, catalysts and reaction results are shown in Table 4. The composition of the raw materials used and the preparation process of the catalyst are shown in Example 1.

[0044] The propane content in the liquefied gas was 7.5% by weight, the propylene content was 2.5% by weight, the butene content was 33.8% by weight, and the butane content was 56.2% by weight. The density of light diesel oil is 0.72 g / cm 3 , the H content was 15.2% by weight, the saturated content was 91.37% by weight, and the aromatic content was 8.63% by weight. Diesel has a density of 0.78 g / cm 3 , the H content is 14.7% by weight, the saturated content is 89.29% by weight, and the aromatic content is 10.71% by weight. Catalytically cracked gasoline (FCC gasoline) is mainly C 5 ~C 10 Hydrocarbons, olefins, alkanes, cycloalkanes, and aromatics are 36.4% by weight and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com