Blast furnace hot blast stove and construction method thereof

A construction method and hot blast stove technology, which can be applied to brick blast furnaces and other directions, can solve the problems that the heat exchange temperature cannot be too high, which is not conducive to lean production, and the waste of hot blast stove space, so as to prolong the heating time, shorten the heating time, save energy cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

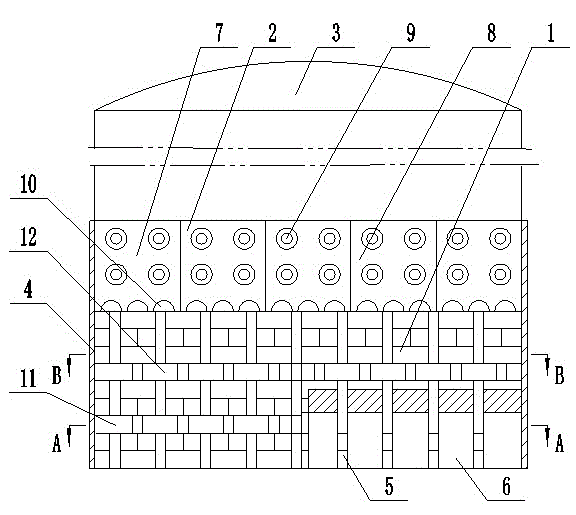

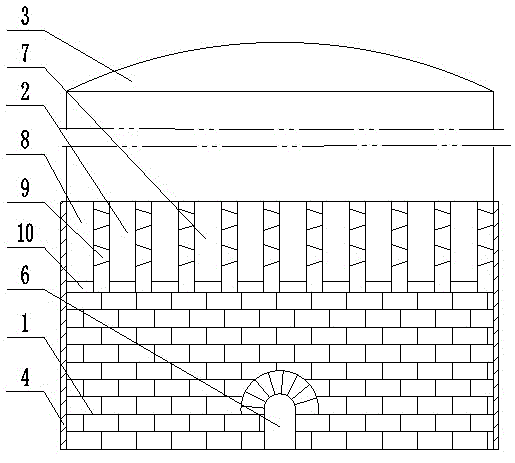

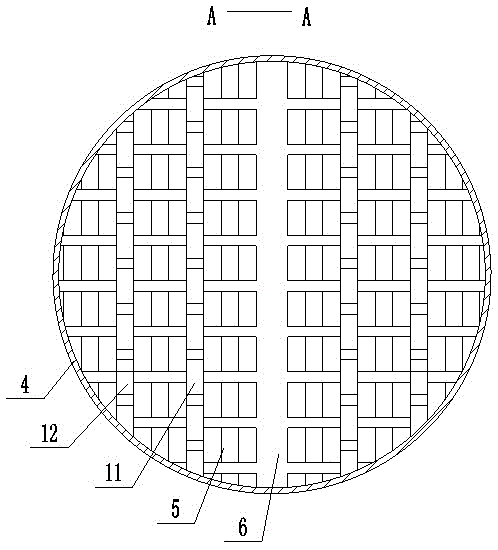

[0032] Such as figure 1 — Figure 4 As shown, a blast furnace hot blast stove of the present invention comprises a furnace bottom 1, a furnace grate 2 and a furnace roof 3, the furnace bottom 1 is a refractory brick, and the structure of the furnace bottom 1 is: the furnace wall 4 is cylindrical, more The bottom wall 5 of the road is equidistantly arranged in parallel in the furnace wall 4, and the two ends of the bottom wall 5 are all connected on the furnace wall 4 and a main air duct 6 is arranged on the side of the furnace wall 4 perpendicular to the direction of the bottom wall 5. The main air duct 6 runs through all the bottom walls 5;

[0033] The circular furnace grate 2 located in the furnace wall 4 is arranged on the bottom wall 5 and the height of the furnace wall 4 is the same as that of the furnace grate 2, and the furnace roof 3 is arranged on the upper part of the furnace grate 2;

[0034] The structure of the grate 2 is: formed by overlapping successively wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com