Method for separating saturated hydrocarbons and aromatic hydrocarbons from lightweight cycle oil

A technology for light cycle oil and aromatics, applied in the preparation of test samples, weighing by removing certain components, etc., can solve problems such as distortion of saturated hydrocarbons and aromatics analysis results, and achieve good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

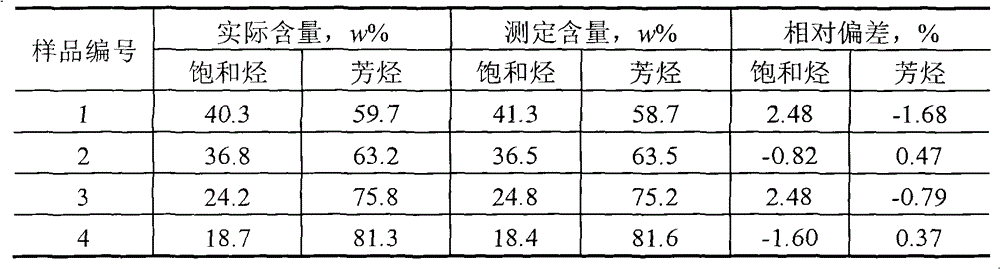

[0022] The accuracy of the method for separating saturated hydrocarbons and aromatics in samples with high aromatics content was investigated.

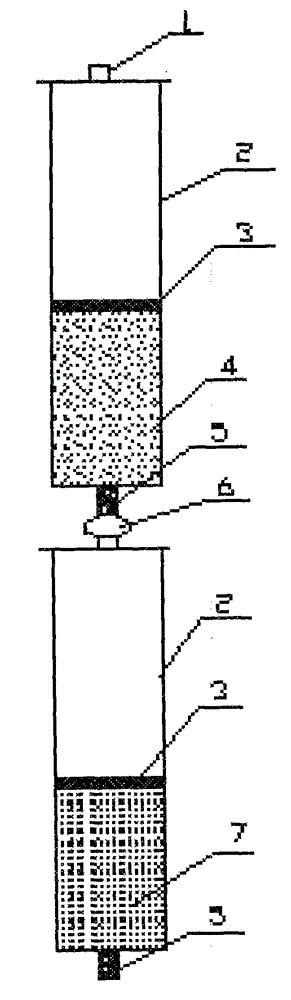

[0023] A solid phase extraction column with a column height of 60 mm and an internal diameter of 70 mm is packed with 1.0 g of active silica, whose particle size is 100)200 mesh. 1.0 g of active neutral alumina is packed in a solid-phase extraction column with a column height of 60 mm and an internal diameter of 7.0 mm, and its particle size is 100)200 mesh. Two solid-phase extraction columns are connected together with a column joint, the silica column is located at the upper part, and the alumina column is located at the lower part.

[0024] According to the method of ASTM D2549, the saturated hydrocarbons and aromatics of diesel oil samples were separated, and after constant weight weighing, four samples with different contents of saturated hydrocarbons and aromatics were prepared. According to the method described in claim 1, fou...

Embodiment 2

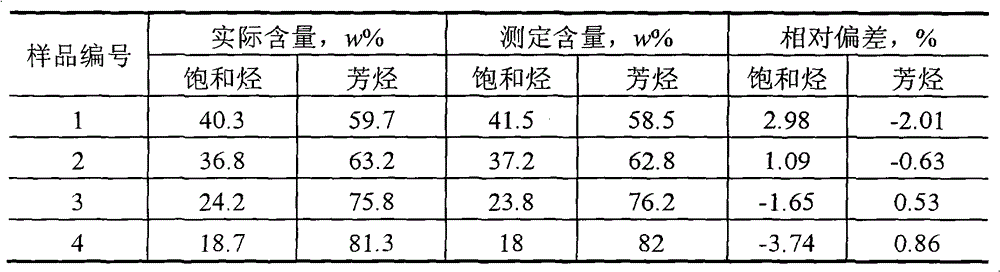

[0029] The accuracy of the method for separating saturated hydrocarbons and aromatics in samples with high aromatics content was investigated.

[0030] A solid phase extraction column with a column height of 60 mm and an internal diameter of 70 mm is packed with 1.0 g of active silica, whose particle size is 100)200 mesh. 1.0 g of active neutral alumina is packed in a solid-phase extraction column with a column height of 60 mm and an internal diameter of 7.0 mm, and its particle size is 100)200 mesh. Two solid-phase extraction columns are connected together with a column joint, the silica column is located at the upper part, and the alumina column is located at the lower part.

[0031] According to the method of ASTM D2549, the saturated hydrocarbons and aromatics of diesel oil samples were separated, and after constant weight weighing, four samples with different contents of saturated hydrocarbons and aromatics were prepared. According to the method described in claim 1, fou...

Embodiment 3

[0036]The accuracy of the method for separating saturated hydrocarbons and aromatics in samples with high aromatics content was investigated.

[0037] Pack 1.0 g of activated silica in a solid-phase extraction column with a column height of 60 mm and an internal diameter of 7.0 mm, and its particle size is 100)200 mesh. 1.0 g of active neutral alumina is packed in a solid-phase extraction column with a column height of 60 mm and an internal diameter of 70 mm, and its particle size is 100)200 mesh. Two solid-phase extraction columns are connected together with a column joint, the silica column is located at the upper part, and the alumina column is located at the lower part.

[0038] According to the method of ASTM D2549, the saturated hydrocarbons and aromatics of diesel oil samples were separated, and after constant weight weighing, four samples with different contents of saturated hydrocarbons and aromatics were prepared. According to the described method of claim 1, four s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com