Structural long-period optical fiber grating

A fiber grating, long-period technology, applied in the direction of cladding fiber, optical waveguide light guide, optical waveguide coupling, etc., can solve the problems of insufficient compact structure, single structure, harsh realization conditions, etc., and achieves simple composition structure and preparation process. The effect of reducing the number of grating periods and enriching the optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

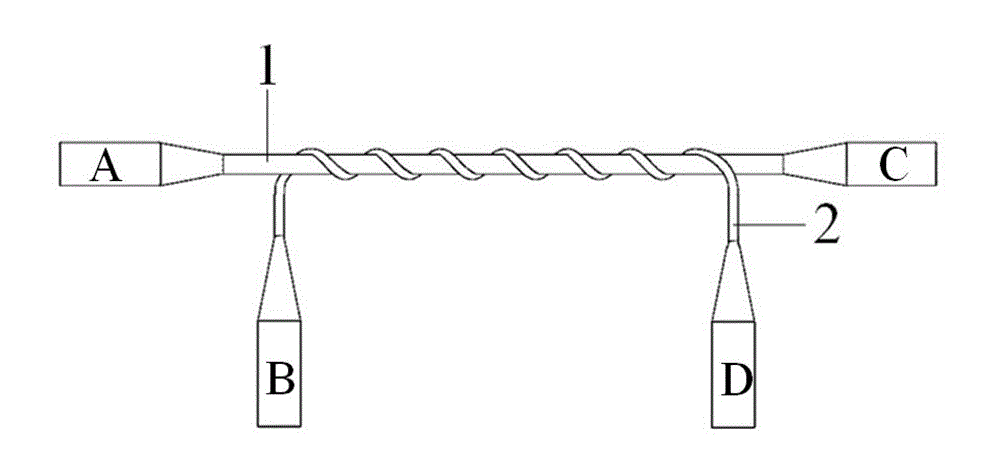

[0029] Such as figure 1 As shown, a structural long-period fiber grating includes a shaft 1 and a helix 2, and a periodic helical structure is formed by winding the helix 2 on the shaft 1, thereby obtaining a long-period fiber grating; it can be seen that the long-period fiber of this embodiment The composition structure and preparation process of the grating are very simple.

[0030] The shaft 1 and the helix 2 are micro-nano silica fibers, micro-nano glass fibers or micro-nano polymer fibers with a cross-sectional diameter of micron or nanometer order; the cross-sectional diameter of the shaft 1 is larger than that of the helix 2. Micro-nano silica optical fiber is obtained by melting and tapering of standard optical fiber; micro-nano glass optical fiber is obtained by melting and drawing of glass fiber or glass melting; micro-nano polymer optical fiber is obtained by melting and drawing of polymer optical fiber or polymer melting; Both ends of the micro-nano silica fiber, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross section diameter | aaaaa | aaaaa |

| Cross section diameter | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com