Wafer temporary bonding method

A temporary bonding and wafer technology, applied in the field of bonding, can solve the problems of long polishing time, residual slurry pollution, increased production costs, etc., and achieve the effect of avoiding the influence of warpage, convenient operation and reducing the influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0028] In order to be able to reduce the impact of warpage on devices after wafer thinning, the present invention uses a temporary bonding method to form a permanent bonding process. Specifically, the temporary wafer bonding method of the present invention includes the following steps:

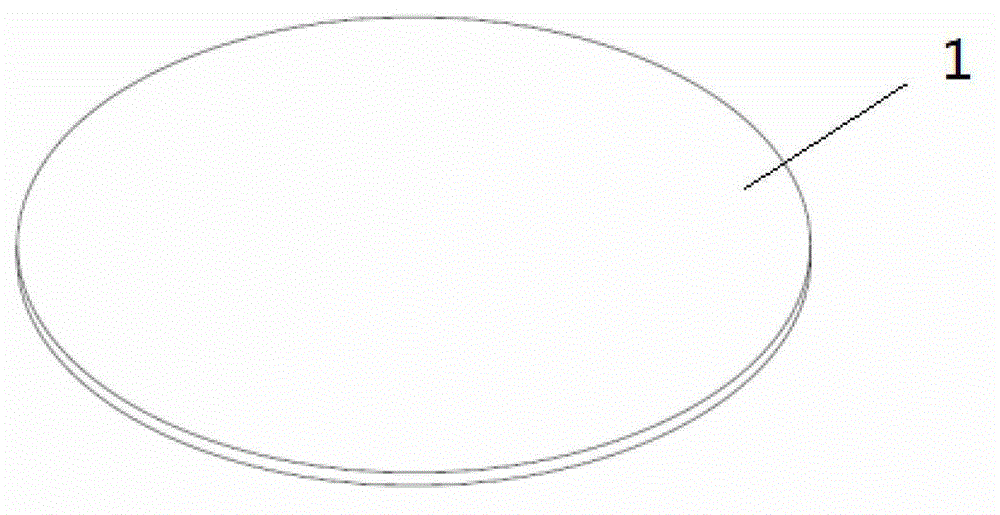

[0029] a. Provide and clean the required first wafer 1 to be bonded;

[0030] like figure 1 As shown: the material of the first wafer 1 includes silicon and germanium, and the first wafer 1 may also use SOI (silicon on insulator);

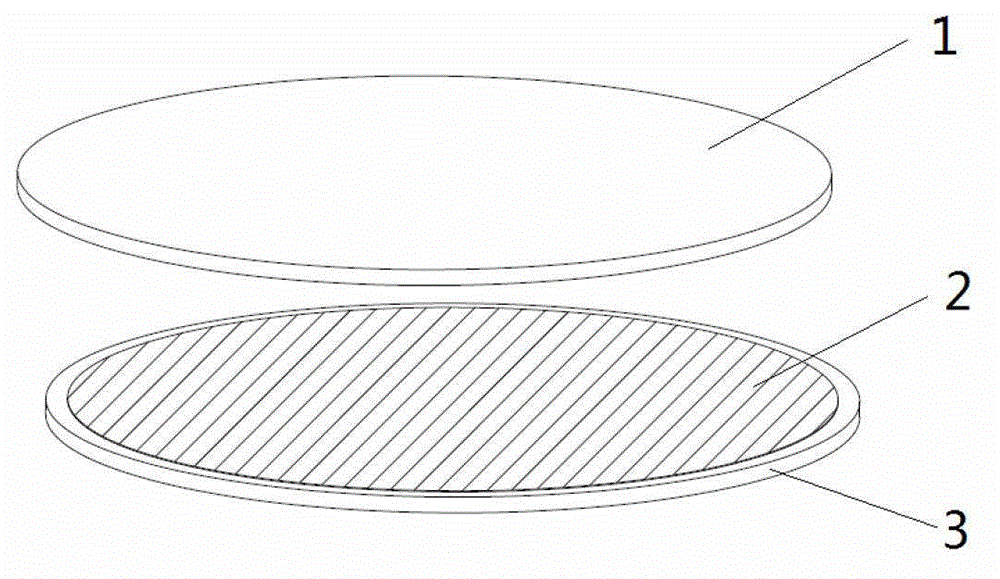

[0031] b. Provide a carrier wafer 2, and spin-coat an adhesive 3 on a surface of the carrier wafer 2;

[0032] like figure 2 As shown: the carrier wafer 2 is a transitional wafer, and the adhesive 3 is made of conventional materials, such as SU-8, etc., which will not be listed here;

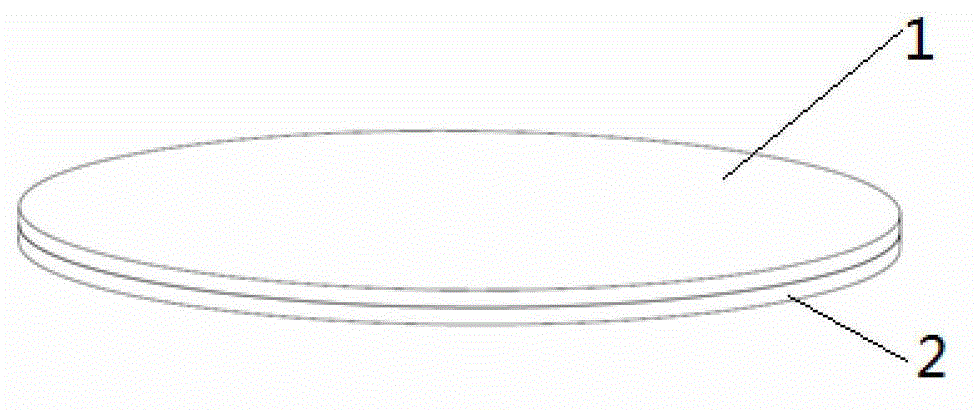

[0033] c. Transfer the above-mentioned first wafer 1 and ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com