Solar energy temperature difference power generation system based on liquid metal thermal switch

A liquid metal, thermoelectric power generation technology, applied in the direction of generators/motors, electrical components, etc., can solve the problems that the output electric energy cannot be accumulated, and the utilization efficiency of thermoelectric heat energy is not high, so as to improve the energy conversion efficiency, the driving power is small, and the system is high The effect of energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

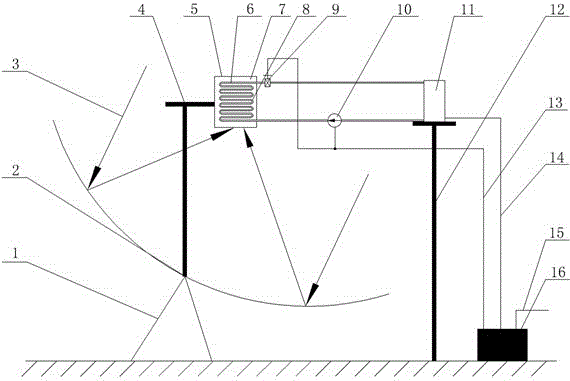

[0022] see Figure 1~2 , a solar thermoelectric power generation system based on liquid metal thermal switches, including:

[0023] The solar concentrator 2 is a focusing structure for collecting solar energy and transferring heat energy to the heat storage device 5;

[0024] The heat storage device 5 is mainly composed of a coil 8 filled with liquid metal 6 and a heat storage material 7 arranged outside the coil for collecting heat energy;

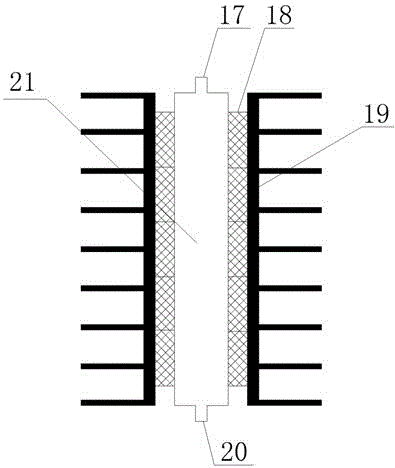

[0025] The thermoelectric power generation assembly 11 is mainly composed of a hot end flow channel 21, a thermoelectric power generation module 18 and a radiator 19; the hot end flow channel 21 is a rectangular channel structure, and its outer wall is a thermoelectric power generation module 18; A radiator 19 is provided; the upper and lower ends of the hot end flow channel 21 are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com