High strength steel sheet having excellent brittle crack resistance and method for manufacturing same

A high-strength steel plate, brittle technology, applied in the field of iation) tools, can solve the problems of increased manufacturing cost and cumbersome manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach )

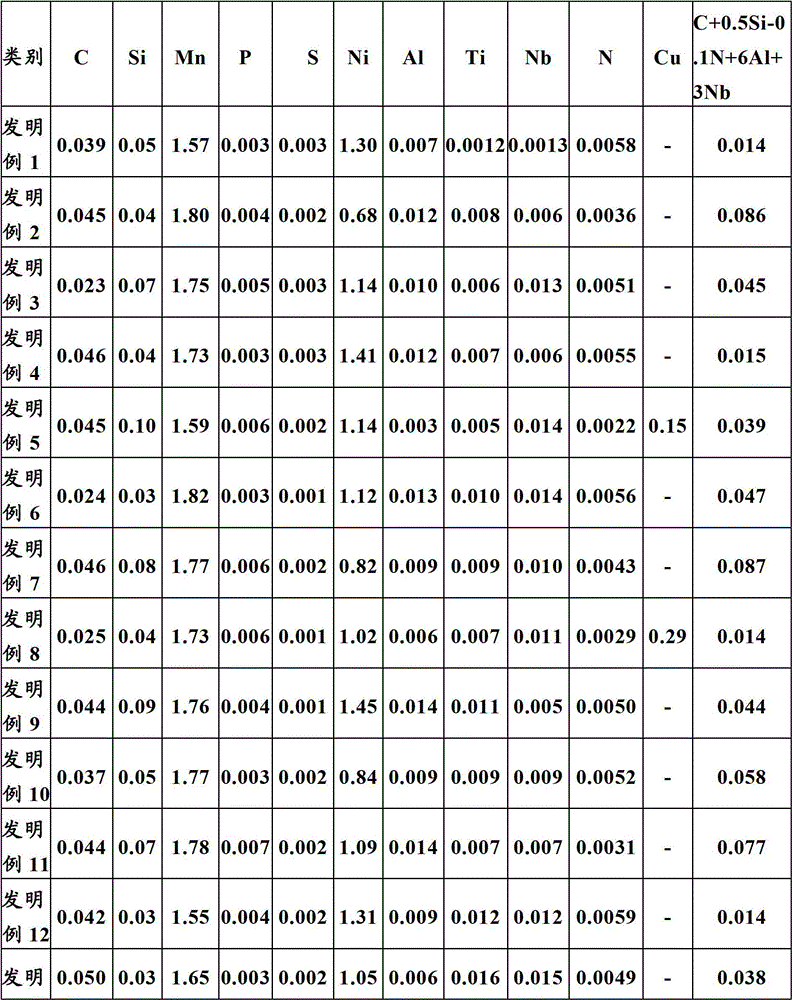

[0068] Molten steel was prepared in a 300-ton electric furnace according to the composition shown in Table 1, and a 300 mm slab was prepared by a continuous casting method. As shown in Table 2, the slabs thus produced were heated and subjected to rough rolling and finish rolling, and steel products were produced through final accelerated cooling.

[0069] The electron backscatter diffraction pattern (EBSP) device installed in the scanning electron microscope (SEM) can be used to measure the effective particle size of the prepared steel plate. The magnification used was in the range of 300X-500X with a step size of 0.75 μm, and the thickness direction of the rolled cross-section and the plate center in the thickness direction were observed. In order to obtain meaningful data values, a minimum of 5000+ grains defined as boundaries with 15°+ grain misorientation was included. The effective particle diameter defined in the present invention is calculated by using software capable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Critical value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com