Method and device for treating a liquid food product

A liquid food and food technology, applied in liquid bottling, food preservation, liquid filling, etc., can solve the problems that the pressure difference cannot maintain uniformity, damage, and damage food quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

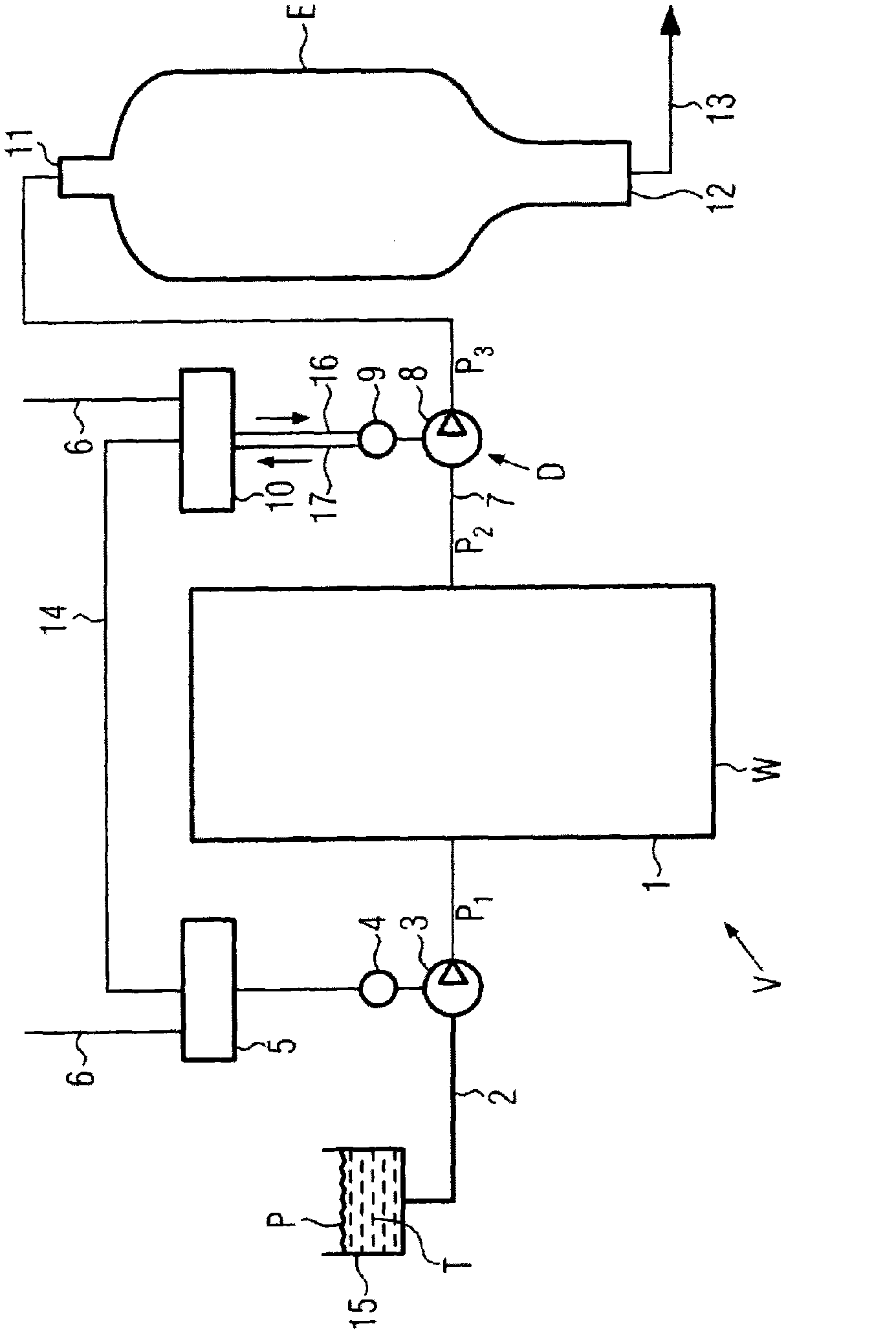

[0021] The device V is used, for example, in filling technology for fruit juice or milk products or the like. The device V is especially suitable for liquid foods comprising solids such as fibres, pulp, pieces of fruit, pieces of fruit and the like, but can also be used for making beer (for example for wort) or for filling yoghurt with additives. during installation.

[0022] The device V has a heat exchanger W defining, for example, a preheating section 1 , in a predetermined product flow from the storage 15 through the supply section 2 , for example by means of an electric feed pump 3 at a predetermined feed pressure P1 , which will contain solids The liquid food P of T is conveyed through the preheating section 1, and the liquid food P is heat-treated such as pasteurization or the like. The supply pump 3 is connected to the electric motor 4 . An electric motor 4 can be included in the charge pump 3 and is connected in an embodiment to a frequency converter 5 , which recei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com