Production method for high-bulk packing board

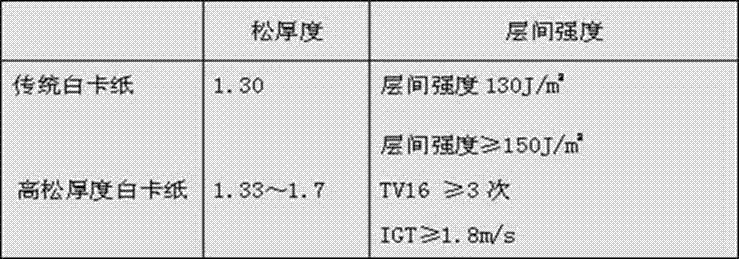

A packaging cardboard and production method technology, applied in the direction of packaging paper, wrapping paper, packaging, etc., can solve the problems of unfavorable environment and resource protection, reduction of white cardboard thickness and stiffness, and large consumption of fiber resources, etc., to achieve favorable Protection of the environment and resources, reduction of wood consumption, and high printing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: A kind of production method of high-bulk packaging cardboard (white cardboard), its specific production process is:

[0016] (1) Prepare the slurries required for the surface layer, lining layer, core layer and bottom layer respectively by disintegration, screening, purification, flotation, heat dispersion, bleaching and refining;

[0017] (2) When mixing the slurry of the lining layer and the core layer in the mixing tank, add bulk thickness ≥ 2.0m to the waste paper pulp used to prepare the lining layer and the core layer 3 / g of mechanical pulp, and mix uniformly to form the mixed pulp required for each layer, wherein in the mixed pulp of the lining layer: the weight percentage of mechanical pulp is 50%, and the weight percentage of chemical pulp and waste paper pulp is 50%. , in the mixed pulp of the core layer: the weight percentage of mechanical pulp is 59%, the weight percentage of chemical pulp and waste paper pulp is 41%;

[0018] (3) Prepare the...

Embodiment 2

[0021] Embodiment 2: A kind of production method of high-bulk packaging cardboard (white cardboard), its specific production process is:

[0022] (1) Prepare the slurries required for the surface layer, lining layer, core layer and bottom layer respectively by disintegration, screening, purification, flotation, heat dispersion, bleaching and refining;

[0023] (2) When mixing the slurry of the lining layer and the core layer in the mixing tank, add bulk thickness ≥ 2.0m to the waste paper pulp used to prepare the lining layer, core layer and bottom layer 3 / g of mechanical pulp, and mix uniformly to form the mixed pulp required for each layer, wherein in the mixed pulp of the lining layer: the weight percentage of mechanical pulp is 60%, and the weight percentage of chemical pulp and waste paper pulp is 40%. In the mixed pulp of the core layer: the weight percentage of mechanical pulp is 73%, the weight percentage of chemical pulp and waste paper pulp is 27%, and in the mixed ...

Embodiment 3

[0027] Embodiment 3: A kind of production method of high-bulk packaging cardboard (white cardboard), its specific production process is:

[0028] (1) Prepare the slurries required for the surface layer, lining layer, core layer and bottom layer respectively by disintegration, screening, purification, flotation, heat dispersion, bleaching and refining;

[0029] (2) When mixing the slurry of the lining layer and the core layer in the mixing tank, add bulk thickness ≥ 2.0m to the waste paper pulp used to prepare the lining layer, core layer and bottom layer 3 / g of mechanical pulp, and mix uniformly to form the mixed pulp required for each layer, wherein in the mixed pulp of the lining layer: the weight percentage of mechanical pulp is 42%, and the weight percentage of chemical pulp and waste paper pulp is 58%. , in the mixed pulp of the core layer: the weight percentage of mechanical pulp is 53%, the weight percentage of chemical pulp and waste paper pulp is 47%;

[0030] (3) P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com