Hydraulic brake system of wind driven generator

A wind turbine and hydraulic braking technology, applied in the control of wind turbines, wind turbines, engines, etc., can solve the problems of large braking kinetic energy, large power consumption, and wind turbine shaft damage, and achieve flexible and reliable braking, The effect of simple structure and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

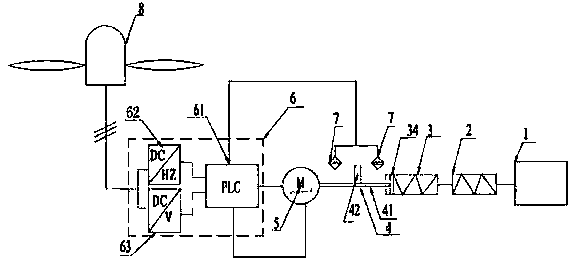

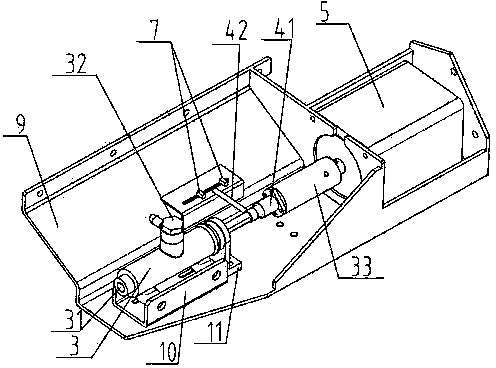

[0027] Such as figure 1 Show, the hydraulic suppression system of the wind turbine, including the one -control module 6 and one for the main shaft or the execution agency of the brake and release of the brake wind power generator 8, at least one to drive the execution agency 1 No. 1 No. 1Two -cylinder body 2, one with a piston 34 and connected to the second cylinder 2, one step into the motor 5, connect to the motor 5 and the first cylinder body 3 3The transmission parts 4 between and axial -oriented movement 4, which is connected to the second cylinder body 2, which is connected to the second cylinder body 2.The motor 5 is running, and the output shaft of the motor 5 is connected to the transmission parts 4, so that the piston 34 of the first cylinder 34 performed axial back and forth in the first cylinder 3.

[0028] In the embodiment, the transmission component 4 of the axial movement is 41, and the roller screw mechanism 41 is connected to the rotation axis of the step motor 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com