Spherical lithium ion battery anode material and preparation method of precursor thereof

A technology for lithium-ion batteries and positive electrode materials, which is applied in the direction of battery electrodes, circuits, electrical components, etc., to achieve the effects of good charge and discharge reversibility and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Preparation of nano-nickel hydroxide: 0.015mol of NiCl 2 ·6H 2 0, 0.03mol of NaOH, respectively dissolved in 25mL water to form a solution, mix the two in a reaction kettle, place them in an oven at 180°C for 24 hours, separate and dry to obtain nano-nickel hydroxide .

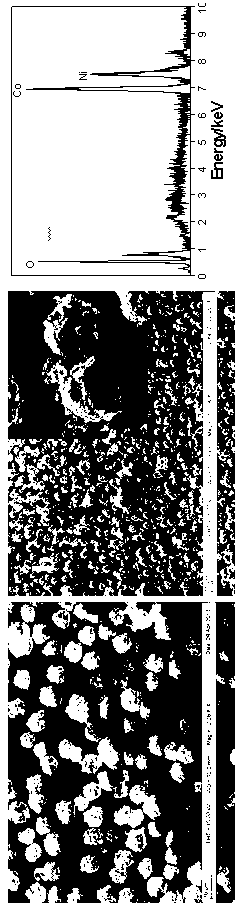

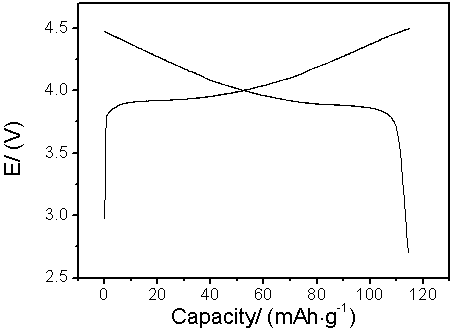

[0023] Preparation of lithium-ion battery cathode material: 0.25 g of the prepared nano-nickel hydroxide was dispersed in 50 mL of distilled water, and 2.57 g of CoCl 2 ·6H 2 O was dissolved in the above system, and the resulting mixture was placed in a reaction kettle and reacted in an oven at 200 °C for 24 hours. After the reaction was completed, it was naturally cooled to room temperature, centrifuged and dried at 60 °C to obtain spherical lithium-ion battery materials. precursor, whose shape is as figure 1 shown in a. Depend on figure 1 It can be seen that the precursor is in the form of spherical particles, and its particle size distribution is relatively uniform, mainly between 8-10 mi...

Embodiment 2

[0026] 0.25 g of the prepared nano-nickel hydroxide was dispersed in 50 mL of distilled water, and 1.93 g of CoCl 2 ·6H 2 O is dissolved in the above system, and the resulting mixture is placed in a reaction kettle and reacted in an oven at 200 °C for 24 hours. After the reaction is completed, it is naturally cooled to room temperature, centrifuged and dried at 60 °C to obtain a spherical lithium-ion battery material precursors.

[0027] Take 1 g of the lithium-ion battery material precursor prepared in the above steps and grind and mix them with 0.28 g of LiOH. After mixing, program the temperature in a muffle furnace to 500 ° C for 5 hours, then calcinate at 750 ° C for 12 hours, and cool naturally After that, the spherical lithium-ion battery material (LiNi 0.23 co 0.77 o 2 ).

Embodiment 3

[0029] 0.25 g of the prepared nano-nickel hydroxide was dispersed in 50 mL of distilled water, and 1.28 g of CoCl 2 ·6H 2 O was dissolved in the above system, and the resulting mixture was placed in a reaction kettle and reacted in an oven at 200 °C for 24 hours. After the reaction was completed, it was naturally cooled to room temperature, and dried at 60 °C after centrifugation to obtain spherical lithium-ion battery materials. Precursor.

[0030] Take 1 g of the lithium-ion battery material precursor prepared by the above steps and grind and mix them with 0.28 g of LiOH. After mixing, program the muffle furnace to 500 ° C for 5 hours, then calcinate at 750 ° C for 12 hours, and cool naturally After that, the spherical lithium-ion battery material (LiNi 0.44 co 0.56 o 2 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com