Anti-mildew and antiseptic treatment method for artificial bamboo boards

An anti-mildew and antiseptic technology, applied in the direction of impregnating wood, manufacturing tools, wood impregnation, etc., can solve the problems of reducing the strength of bamboo products, large environmental impact, affecting appearance, etc., to reduce labor costs, high degree of automation, and improve labor. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

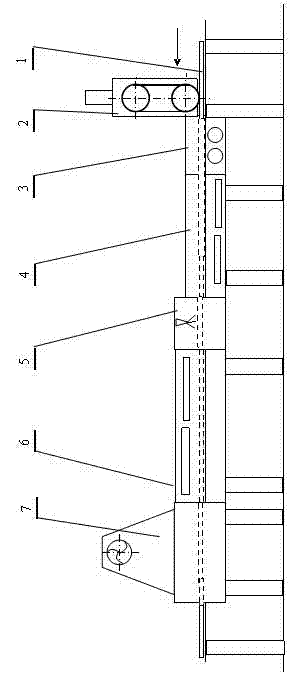

Image

Examples

Embodiment 1

[0027] The method for automatic anti-corrosion and anti-mildew treatment of bamboo recombined wood flooring for outdoor use comprises the following process steps:

[0028] 1. The net width of the bamboo composite wood floor surface is 90-210mm;

[0029] 2. Dilute the water-based colorless bamboo wood mildew-proof preservative (model ZJFC-I) of propiconazole with water to an aqueous concentrate of 2.0% (weight ratio) of active ingredients;

[0030] 3. Adjust the coating amount of propiconazole water-based colorless bamboo wood anti-mold preservative (ZJFC-I) aqueous solution, so that the single-side roller coating amount is 15g / m2, and the single-side spraying amount is about 20g / m2;

[0031] 4. Put the bamboo reconstituted wood floor into the assembly line from the feed port, and use the sander 2 to sand the surface and determine the thickness, and the feed speed is about 15m / min;

[0032] 5. After sanding with sanding rollers, use a double-roller back roller coater 3 to roll...

Embodiment 2

[0038] The method for the anti-mildew and anti-corrosion automatic treatment of the bamboo curtain laminated board and the bamboo-wood composite laminated board for the carriage floor comprises the following process steps:

[0039] 1. Bamboo curtain laminates and bamboo-wood composite laminates are used for the floor of the carriage, with a surface width of 250-610mm;

[0040] 2. Dilute the water-based colorless bamboo wood mildew-proof preservative (model ZJFC-I) of propiconazole with water to an aqueous concentrate of 1.0% (weight ratio) of active ingredients;

[0041] 3. Adjust the coating amount of propiconazole water-based colorless bamboo wood anti-mold preservative (ZJFC-I) aqueous solution, so that the single-side roller coating amount is 10 g / m2, and the single-side spraying amount is about 15 g / m2;

[0042] 4. Enter the assembly line with bamboo curtain laminated board and bamboo-wood composite laminated board from the feed port, and use the sander 2 to sand the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com