Composite roll outer periphery material and preparation method thereof

A composite roll and outer ring technology, applied in the direction of fireproof coatings, etc., can solve the problems of easy wear and cracking, short service life, etc., and achieve the effect of good extrusion resilience, long service life and ideal overall bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

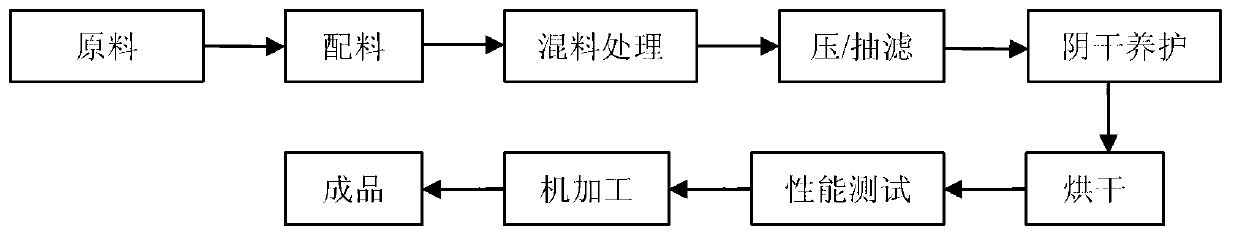

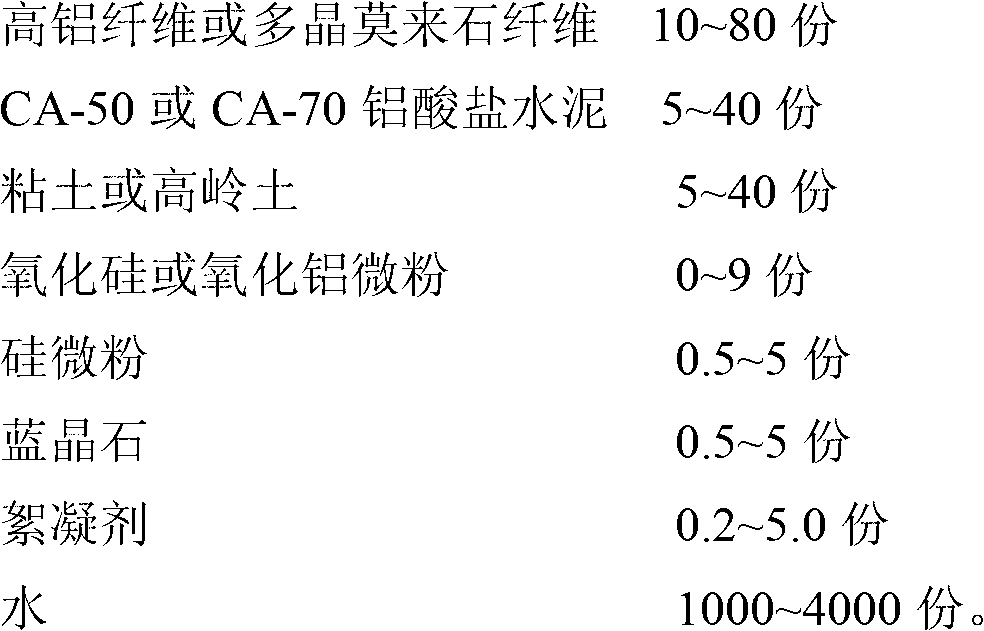

[0043] Accurately weigh the following raw materials: 400 grams of high alumina fiber, 250 grams of CA-50 aluminate cement, 250 grams of kaolin, 60 grams of alumina micropowder, 20 grams of silica micropowder, 20 grams of kyanite, plus flocculant ( Cationic polyacrylamide) 7.0 g, water 15000 ml, mixed by mechanical stirring for about 30 minutes, until the slurry has good fluidity and good dispersibility on the hand, stop stirring.

[0044] The above slurry is subjected to vacuum filtration on a suction filter, and the upper and lower surfaces are required to be flat, and then taken out for machine press molding. After press filtration, the moisture content of the product is controlled at about 20-30%. After taking out the mold, carry out dry curing in the shade for 24 hours, and then bake in an environment of 110°C for 8 hours.

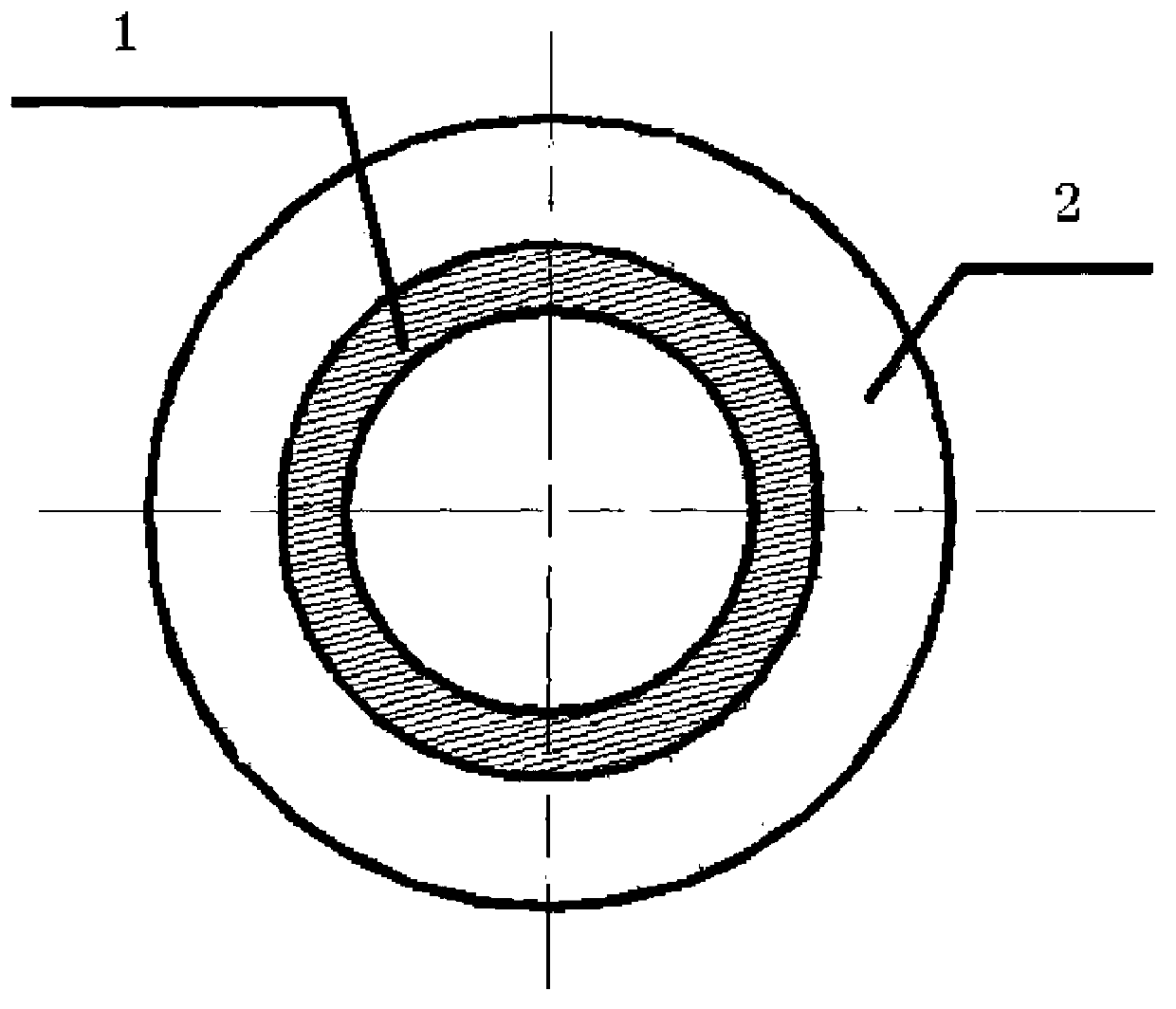

[0045] as attached figure 1 Shown: the dried green body is punched into a ring on a punching machine (i.e., the outer ring 2 of the high-temperature-re...

Embodiment 2

[0047] Accurately weigh the following raw materials: 450 grams of high alumina fiber, 270 grams of CA-50 aluminate cement, 315 grams of clay, 45 grams of alumina micropowder, 22.5 grams of silica micropowder, 22.5 grams of kyanite, plus flocculant ( Cationic polyacrylamide) 7.5 grams, water 16000ml, mixed by mechanical stirring method for about 30 minutes, until the slurry has good fluidity and good dispersibility on the hand, stop stirring.

[0048] Filter the above slurry on a filter press with a pressure of 0.6~1.0MPa. The upper and lower surfaces are required to be smooth, and the moisture content of the product after the filter is controlled at about 20~30%. After taking out the mold, carry out dry curing in the shade for 24 hours, and then bake in an environment of 110°C for 8 hours. Put the dried green body on the heat-resistant steel roll core, and use a lathe for metal processing to trim the billet to prepare a high-temperature-resistant and long-life composite roll. ...

Embodiment 3

[0050] Accurately weigh the following raw materials: 374 grams of polycrystalline mullite fiber, 225 grams of CA-70 aluminate cement, 225 grams of kaolin, 75 grams of alumina micropowder, 18.7 grams of silica micropowder, 18.7 grams of kyanite, Add 7.0 grams of flocculant (cationic polyacrylamide) and 15,000 ml of water, mix them with mechanical stirring for about 30 minutes, and stop stirring until the slurry has good fluidity and good dispersibility.

[0051] Filter the above slurry on a filter press with a pressure of 0.6~1.0MPa. The upper and lower surfaces are required to be smooth, and the moisture content of the product after the filter is controlled at about 20~30%. After taking out the mold, carry out dry curing in the shade for 24 hours, and then bake in an environment of 110°C for 8 hours. Put the dried green body on the heat-resistant steel roll core, and use a lathe for metal processing to trim the billet to prepare a high-temperature-resistant and long-life compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com