Overwater unpowered microalgae culture method and floating island system

A technology of microalgae cultivation and floating island, applied in microorganism-based methods, biochemical equipment and methods, biological material sampling methods, etc. The effect of pumping energy, reducing cultivation cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

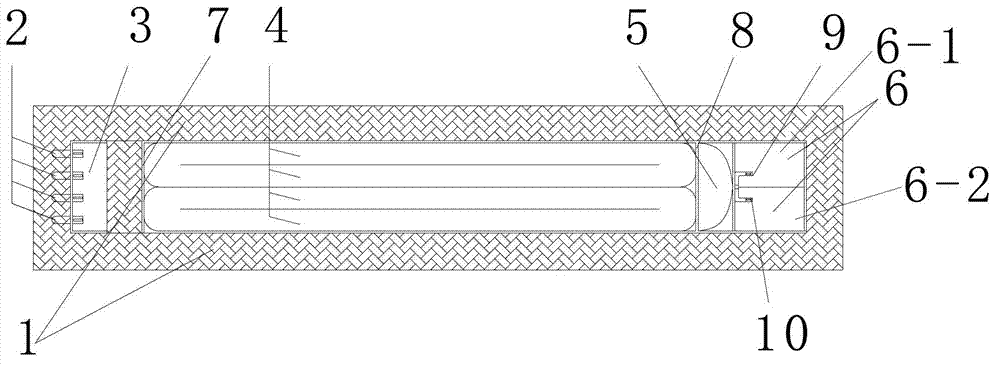

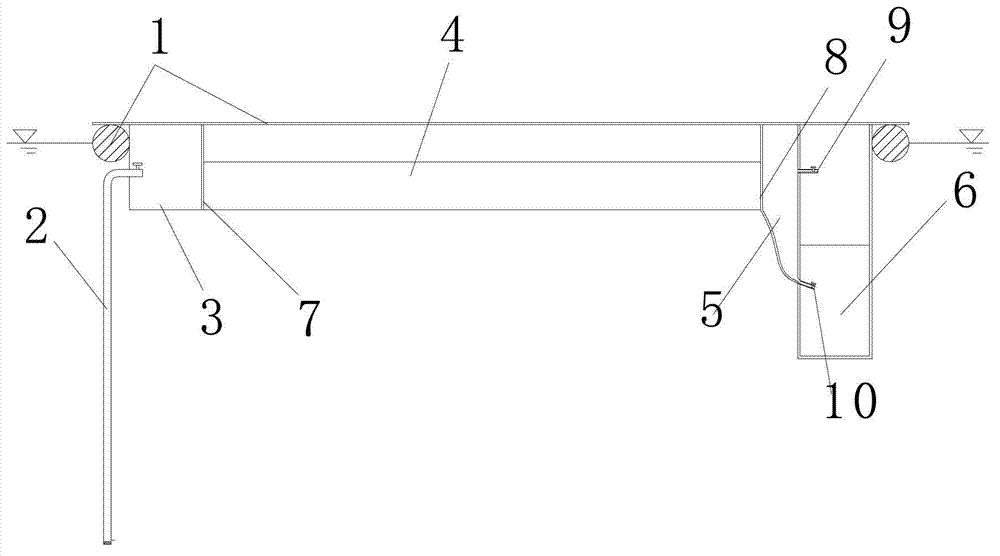

[0032] A method for cultivating open microalgae on water and a floating island system, using steel materials to weld an annular steel frame 1-1, erecting buoys 1-2 under the steel frame 1-1, and laying bamboo springboards on the steel frame 1-1, An annular floating bed 1 that is hollow inside and surrounded by aisles is formed. Then use angle steel to divide the hollow part of the annular floating bed 1 into four parts of different sizes according to the requirements, and fill the four hollow parts with open water frames of different sizes made of polyethylene materials, and form the treatment pool 3 and the cultivation pool in turn. 4. Sedimentation tank 5 and collection tank 6.

[0033] Among them, the bottom of the treatment tank 3 and the cultivation tank 4 is 0.5 m lower than the buoy, and the partition board separates the cultivation tank 4 into four parts, forming a loop-type cultivation tank.

[0034] The shape of the sedimentation tank 5 is a streamline funnel shape,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com