Hollow combined filling wall and construction method thereof

A construction method and filling wall technology, which is applied to building components, buildings, building structures, etc., can solve the problems of increased cost of the main structure, low strength of filling walls, and increased cost of filling walls, etc., to achieve fast on-site installation and improve production The degree and construction efficiency, the effect of ingenious and simple construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

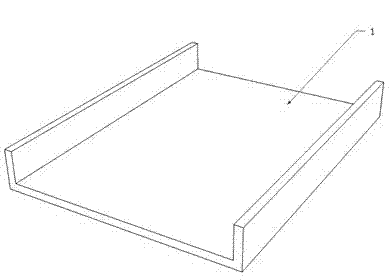

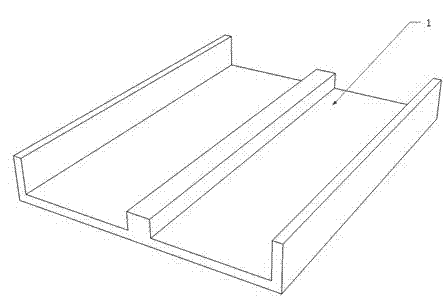

[0033] Example 1: Prefabricated trough-shaped member 1 (groove depth 90, width 600, length 2800, plate thickness 25, cross-section in the shape of "concave") is transported to the construction site after mass production of industrial waste phosphogypsum, such as Figure 4 The prefabricated trough-shaped components 1 are arranged in two rows with half-cross-sectional width buckles, and the two ends are fixed on the upper and lower floors for positioning. Adhesive gypsum caulking and plastering are used for veneering, and the grooves are filled with thermal insulation materials.

Embodiment 2

[0034] Example 2: Prefabricated trough member 1 (groove depth 90, width 600, length 2800, plate thickness 25, cross-section "concave") is transported to the construction site after mass production with cement mortar, such as Figure 5 Arrange two groups of prefabricated trough-shaped components 1 end-to-end along the cross-sectional direction, and then arrange one group vertically and one group horizontally, and connect the groove surfaces to each other for combination. , Paint the gypsum finish, and fill the groove with thermal insulation material.

Embodiment 3

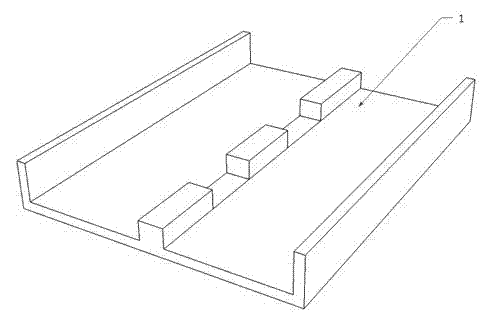

[0035] Example 3: Prefabricated trough-shaped member 1 (groove depth 90, width 600, length 2800, plate thickness 25, cross-section in the shape of "concave") is transported to the construction site after mass production of industrial waste phosphogypsum, such as Image 6 A three-row combination is adopted, the outer two rows of prefabricated trough members 1 face each other, and the middle group is arranged in a staggered manner according to the opposite direction of the adjacent trough surfaces and is offset from the outer two rows by half the width, and the two ends are fixed on the upper and lower floors for positioning , use adhesive plaster caulking, plaster plaster finish, and fill the groove with thermal insulation material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com