Direct drive wind turbine with a thermal control system

一种风力涡轮机、驱动型的技术,应用在控制机械能、风力发动机、风力电机组合等方向,能够解决不充分、风力涡轮机中油泄漏、油润滑系统复杂等问题,达到避免热压缩、提高可靠性和寿命、避免热膨胀的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

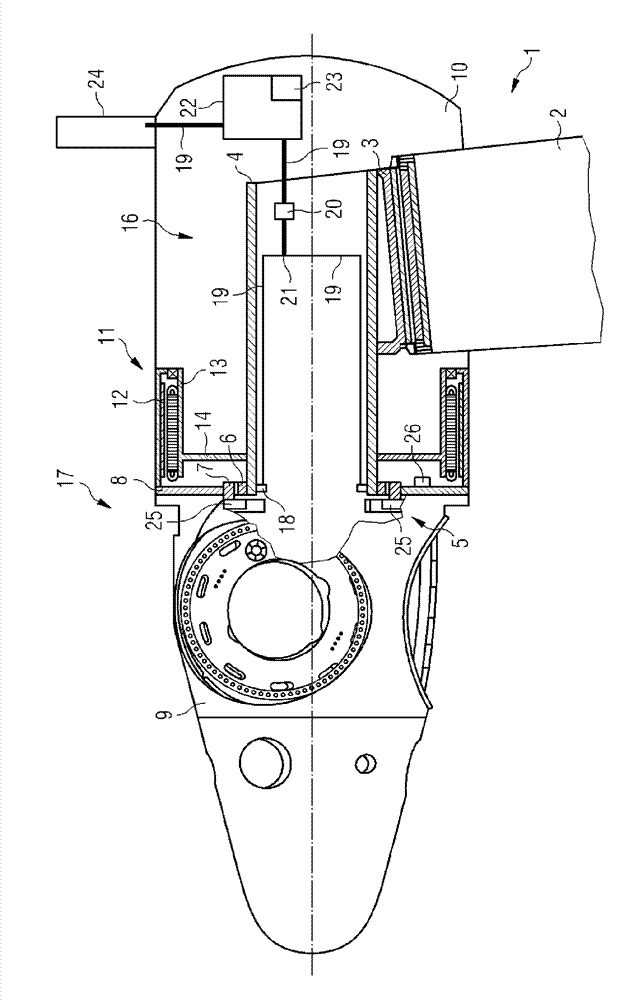

[0041] In the following detailed description, reference is made to the accompanying drawings, which form a part hereof, and in which are shown, for purposes of illustration, specific embodiments in which the invention may be practiced. In this regard, directional terms such as "top" or "bottom" etc. are used with reference to the orientation of the figure(s) being described. Because components of an embodiment may be positioned in a number of different orientations, directional terms are used for purposes of illustration and are in no way limiting. It is to be understood that other embodiments may be utilized and structural or logical changes may be made without departing from the scope of the present invention. Therefore, the following detailed description is not to be taken in a limiting sense, but the scope of the invention is defined by the appended claims.

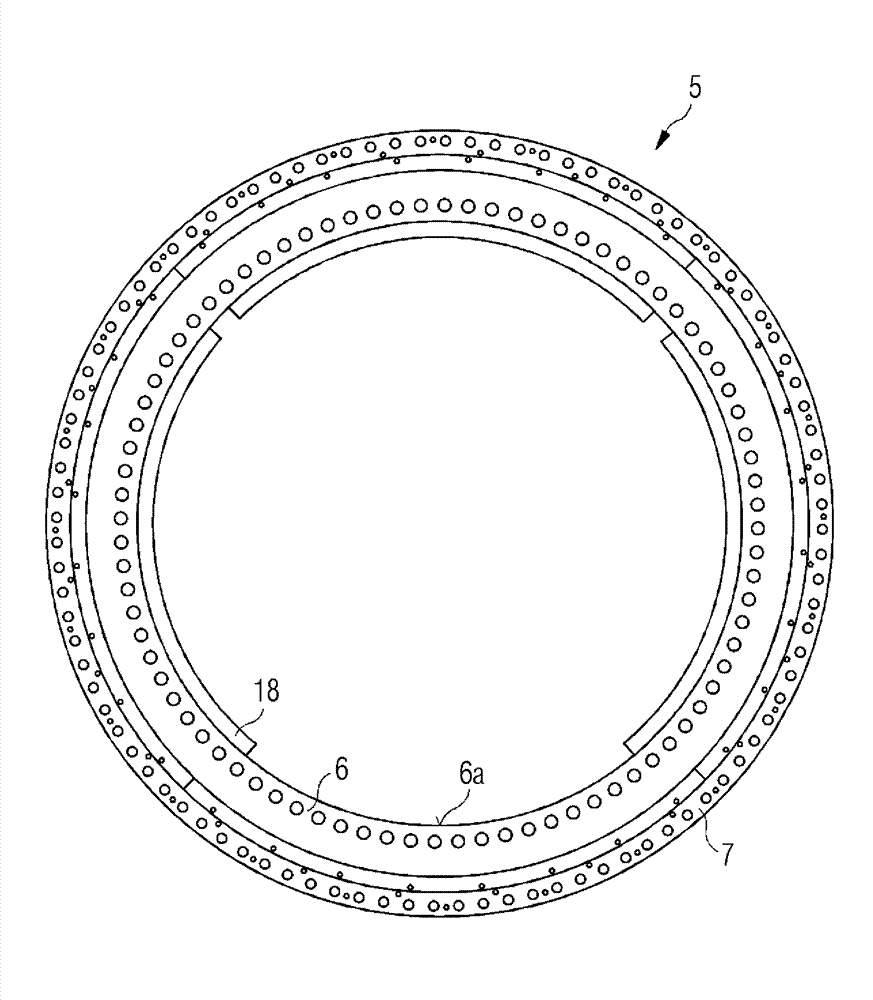

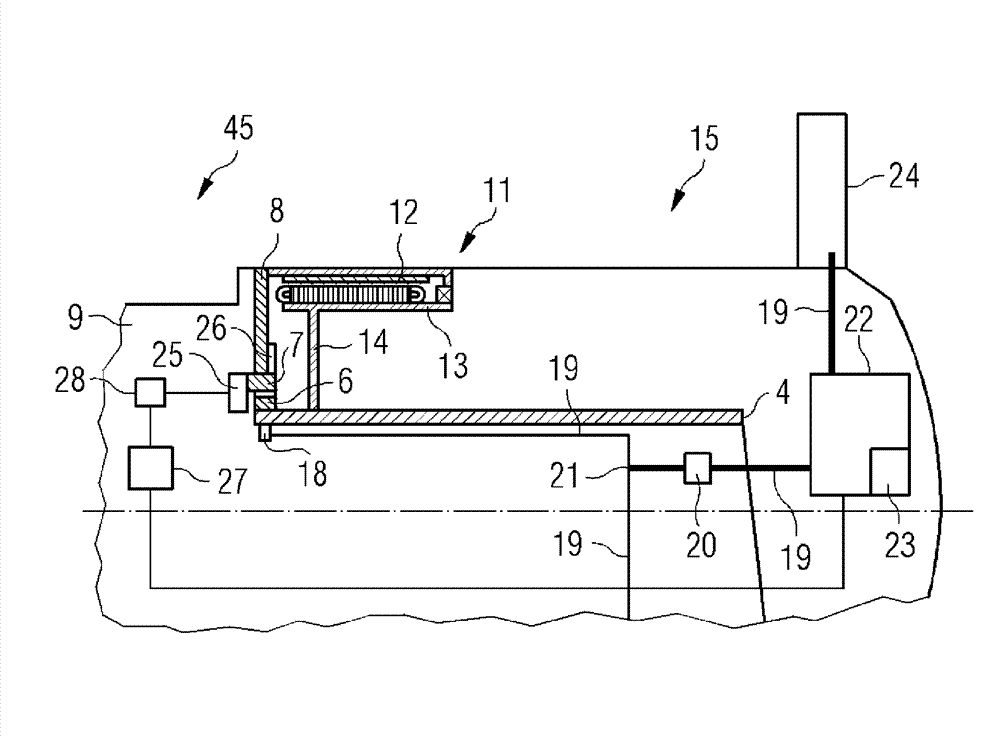

[0042] The wind turbine 1 has a tower 2 which is fixed to the ground and carries the entire structure of the wind ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com