10MN microcomputer-controlled electro-hydraulic servo force standard machine and application method thereof

A technology of microcomputer control and servo force, which is applied in the calibration/testing of force/torque/power measuring instruments, measuring devices, instruments, etc. It can solve problems such as overshooting and the influence of verification results, achieve a large detection range and improve accuracy and stability, control delicate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

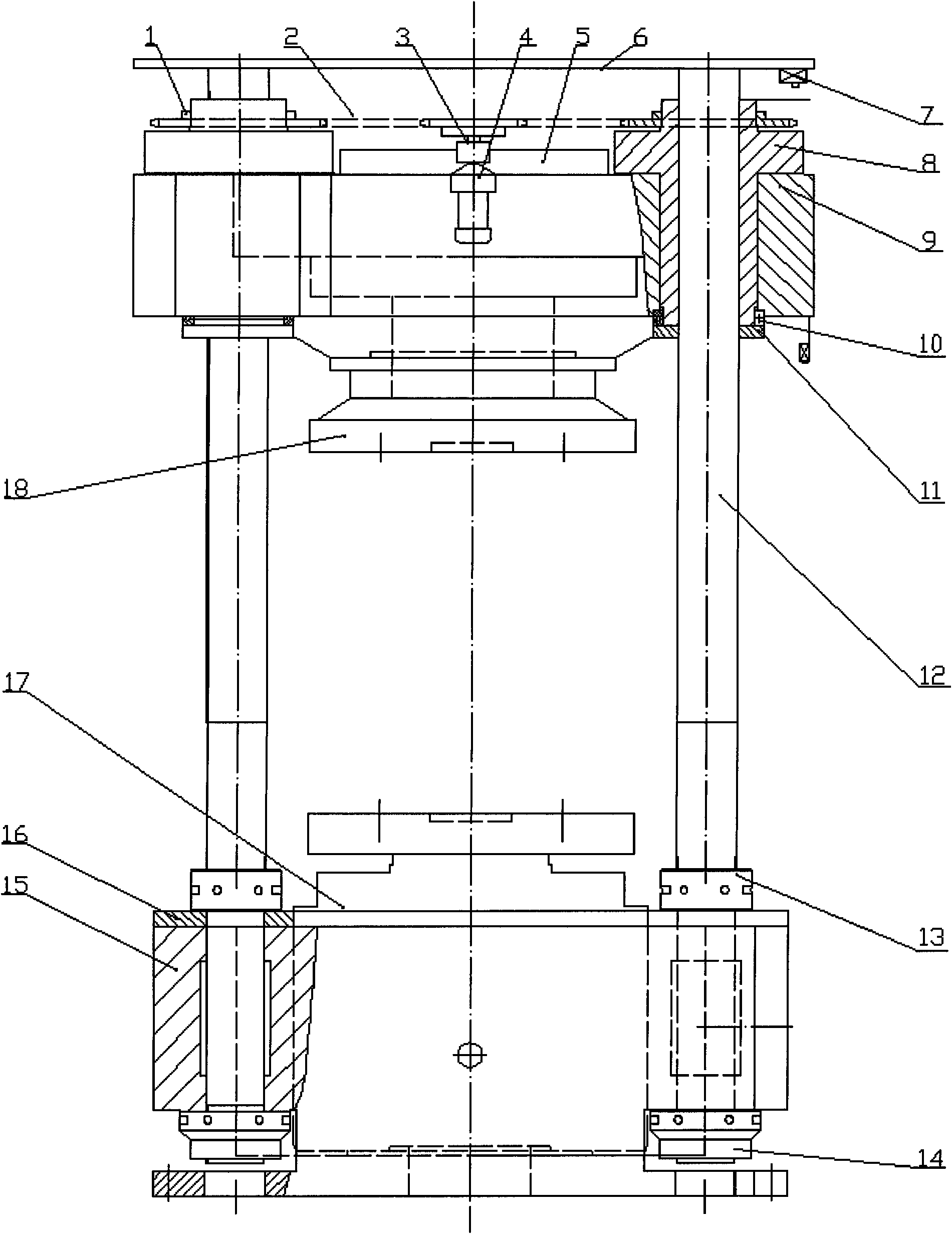

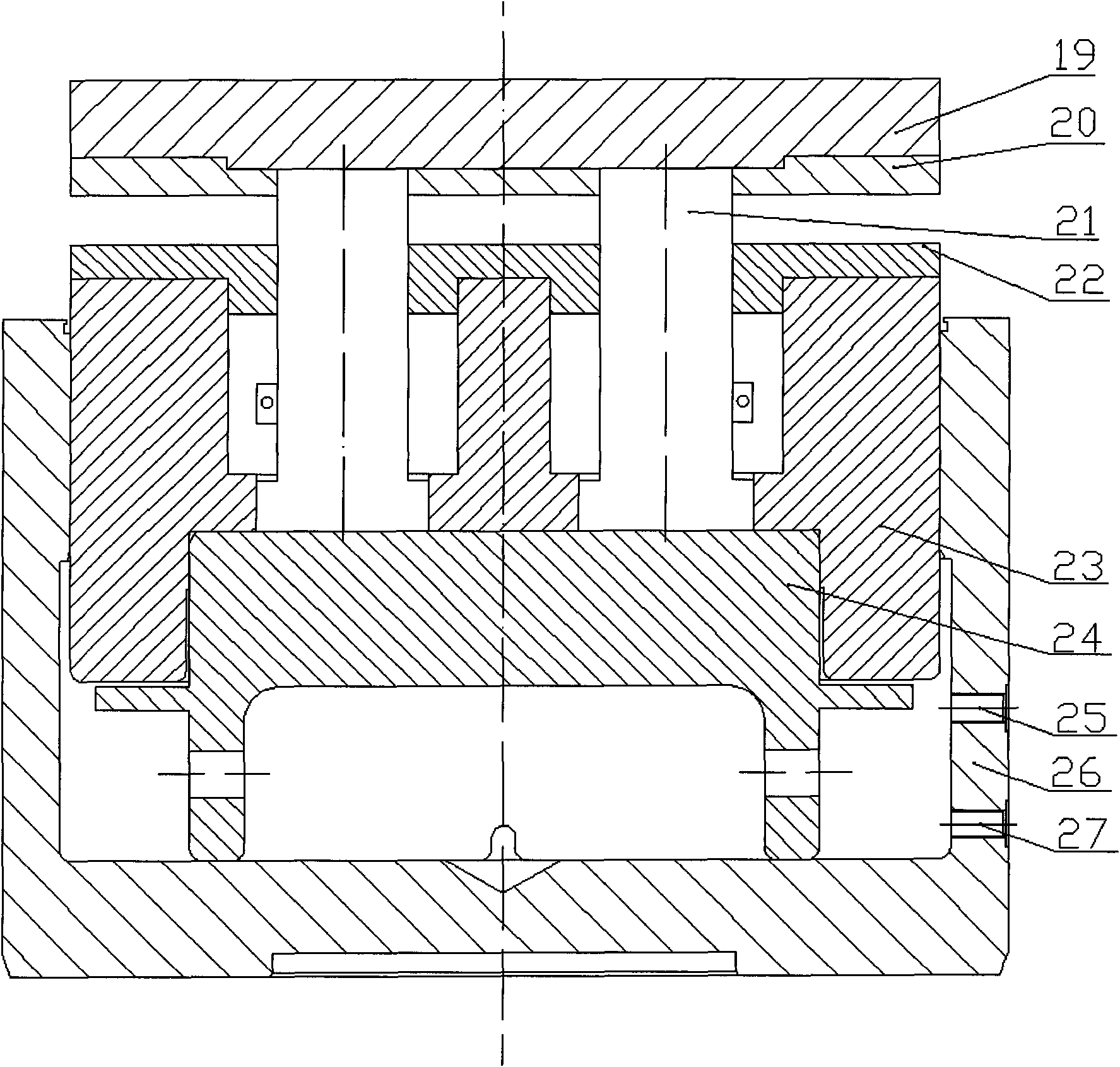

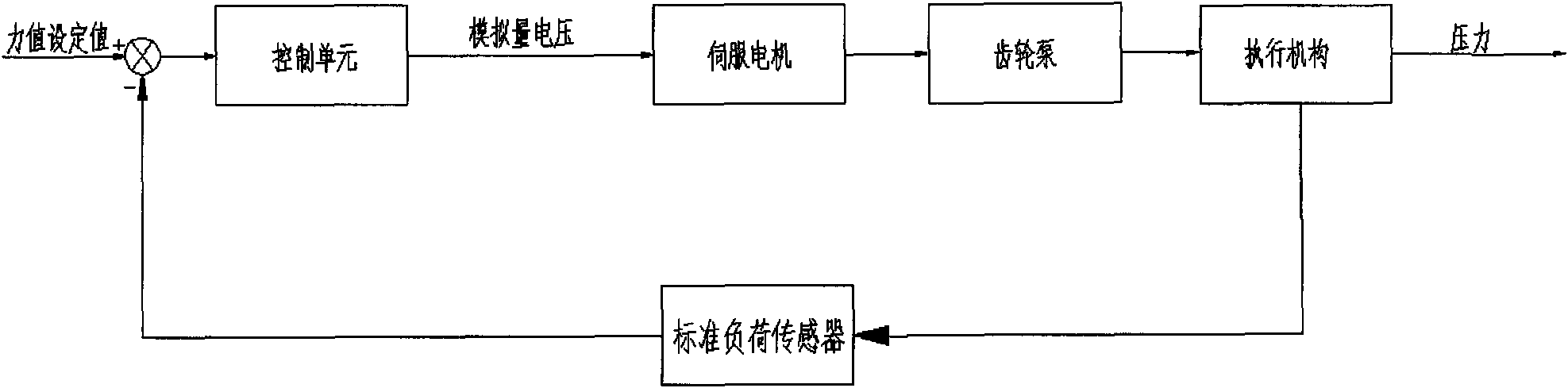

[0019] Such as figure 1 , 2 , 3, the 10MN microcomputer-controlled electro-hydraulic servo force standard machine includes an actuator and a control system; the actuator includes a driven sprocket 1, a drive roller chain 2, a reducer 3, an AC motor 4, a chain drive mechanism 5, a machine Cover top plate 6, beam travel limit switch 7, drive screw sleeve 8, beam 9, bearing 10, bearing support plate 11, lead screw 12, upper nut 13, lower nut 14, base 15, base cover 16, lifting mechanism 17. Upper plate seat 18, lower plate seat 19, lower plate seat positioning plate 20, standard load sensor 21, plunger cover 22, plunger 23, plunger base 24, oil inlet 25, cylinder body 26 and oil outlet Port 27; the shaft of the AC motor 4 is connected to the chain transmission mechanism 5 through the reducer 3, the chain transmission mechanism 5 is connected to the driven sprocket 1 through the transmission roller chain 2, and the driven sprocket 1 is fixed on the drive screw sleeve 8. , The trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com