Special culture medium for Lilium spp. and Lilium spp. culture method

A cultivation medium and technology for lily, applied to soilless cultivation medium of lily and the field of lily cultivation, can solve problems such as unfavorable growth of lily, insignificant effect, low land utilization rate, etc., so as to improve land utilization rate, reduce pollution and harm, The effect of robust plant growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

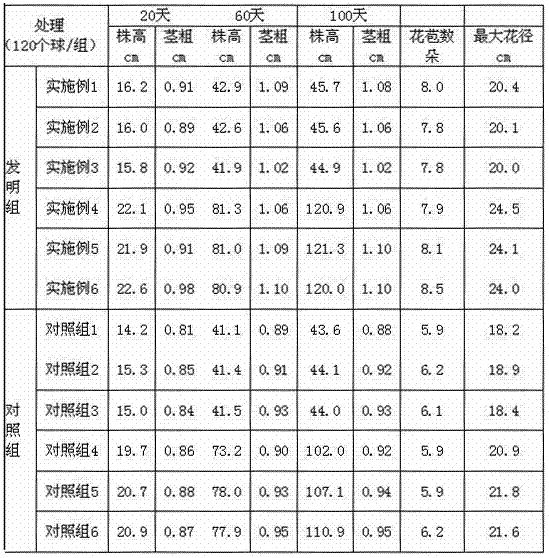

Examples

Embodiment 1

[0033] The configuration of special cultivation medium for lily and the cultivation steps of lily:

[0034] Step a: Mix the following components evenly according to the corresponding requirements and volume percentage: white peat, fiber length 0~5mm, pH6.2, volume percentage 28%; black peat, fiber length 0~5mm, pH6.2, volume percentage 12% %; fermented pine scales, particle size 3~6mm, accounting for 30% by volume; perlite, 30%.

[0035] Step b: Add medical stone with a particle size of 3-5mm to the uniformly mixed medium in step a in an amount of 2.6kg / m3 and mix evenly.

[0036]Step c: Add Aibeishi trace element controlled-release fertilizer to the uniformly mixed medium in step b in an amount of 0.6kg / m3 and mix evenly.

[0037] Step d: Put the medium prepared after step c in a flower pot with a caliber of 18 cm for later use.

[0038] Step e: According to the specification of 3 bulbs / pot, plant the 16 / 18 specification potted lily variety 'Sunshine Bonaire' in the flowerp...

Embodiment 2

[0040] The configuration of special cultivation medium for lily and the cultivation steps of lily:

[0041] Step a: Mix the following components evenly according to the corresponding requirements and volume percentage: white peat, fiber length 0~5mm, pH6.1, volume percentage 29%; black peat, fiber length 0~5mm, pH6.1, volume percentage 10% %; pine scale fermented type, particle size 3~6mm, accounting for 32% by volume; perlite, 29%.

[0042] Step b: Add medical stone to the uniformly mixed medium in step a in an amount of 2.9kg / m3 and mix uniformly.

[0043] Step c: Add Aibeishi trace element controlled-release fertilizer to the uniformly mixed medium in step b in an amount of 0.8kg / m3 and mix evenly.

[0044] Step d: Put the medium prepared after step c in a flower pot with a caliber of 18 cm for later use.

[0045] Step e: According to the specification of 3 bulbs / pot, plant the 16 / 18 specification potted lily variety 'Sunshine Bonaire' in the flowerpot in step d.

Embodiment 3

[0047] The configuration of special cultivation medium for lily and the cultivation steps of lily:

[0048] Step a: Mix the following components evenly according to the corresponding requirements and volume percentage: white peat, fiber length 0~5mm, pH6.4, volume percentage 30%; black peat, fiber length 0~5mm, pH6.4, volume percentage 10% %; pine scale fermented type, particle size 3~6mm, accounting for 32% by volume; perlite, 28%.

[0049] Step b: Add medical stone to the uniformly mixed medium in step a in an amount of 3.0kg / m3 and mix uniformly.

[0050] Step c: Add Aibeishi trace element controlled-release fertilizer to the uniformly mixed medium in step b at an amount of 0.7kg / m3 and mix evenly.

[0051] Step d: Put the medium prepared after step c in a flower pot with a caliber of 18 cm for later use.

[0052] Step e: According to the specification of 3 bulbs / pot, plant the 16 / 18 specification potted lily variety 'Sunshine Bonaire' in the flowerpot in step d.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com