Strengthening maize powder and preparation method thereof

A production method and technology of corn flour, applied in food preparation, application, food science and other directions, can solve the problems of rough taste, poor viscoelasticity, poor palatability, etc., and achieve retention of nutrients and flavor characteristics, good quality, and increased viscoelasticity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

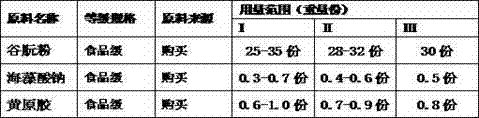

[0075] A kind of gluten-enhanced corn flour of the present invention is made up of the raw material of following weight part:

[0076] Main ingredient: modified corn flour 100kg;

[0077] Excipients: gluten powder 28 kg, sodium alginate 0.6 kg, xanthan gum 0.6 kg.

[0078] Make it as follows:

[0079] Step a: preparation of main ingredient modified corn flour

[0080] (a1) Cleaning: Put the crushed corn groats into a washing machine to clean them, and the cleaned corn groats must not be mixed with foreign impurities;

[0081] (a2) Soaking: transfer the cleaned corn groats to a soaking tank, add soaking water at a ratio of 1:8 to the mass ratio of the material to liquid, and add 0.8% of the weight of the corn groats by pullulanase and corn groats 1.2% papain by grain weight, keep the temperature at 55°C, and soak for 6 hours;

[0082] (a3) Refining: Drain the soaking liquid, rinse with clear water for 2-3 times, and then put it into a refiner for rough grinding. The mass ra...

Embodiment 2

[0092] A kind of gluten-enhanced corn flour of the present invention is made up of the raw material of following weight part:

[0093] Main ingredients: modified corn flour 100kg;

[0094] Excipients: gluten powder 35 kg, sodium alginate 0.4 kg, xanthan gum 1.0 kg.

[0095] Make it as follows:

[0096] Step a: preparation of main ingredient modified corn flour

[0097] (a1) Cleaning: Put the crushed corn groats into a washing machine to clean them, and the cleaned corn groats must not be mixed with foreign impurities;

[0098] (a2) Soaking: Transfer the cleaned corn groats to a soaking tank, add soaking water at a ratio of 1:8 to the mass ratio of material to liquid, and add 1.5% of the weight of corn groats by pullulanase and corn groats 0.6% papain by grain weight, keep the temperature at 65°C, and soak for 4 hours;

[0099] (a3) Refining: Drain the soaking liquid, rinse with clear water for 2-3 times, and then put it into a refiner for rough grinding. The mass ratio of ...

Embodiment 3

[0109] A kind of gluten-enhanced corn flour of the present invention is made up of the raw material of following weight part:

[0110] Main ingredients: modified corn flour 100kg;

[0111] Excipients: gluten powder 30 kg, sodium alginate 0.5 kg, xanthan gum 0.8 kg.

[0112] Make it as follows:

[0113] Step a: preparation of main ingredient modified corn flour

[0114] (a1) Cleaning: Put the crushed corn groats into a washing machine to clean them, and the cleaned corn groats must not be mixed with foreign impurities;

[0115] (a2) Soaking: Transfer the cleaned corn groats to a soaking tank, add soaking water at a ratio of 1:8 to the mass ratio of material to liquid, and add 0.5% of the weight of corn groats by pullulanase and corn groats 1.0% papain by grain weight, keep the temperature at 60°C, and soak for 5 hours;

[0116] (a3) Refining: Drain the soaking liquid, rinse it with clear water for 2-3 times, and then put it into a refiner for rough grinding. The mass ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com