Preparation method for producing ainothiazoly loximate by utilizing phase transfer technology

An aminothioxamic acid and phase transfer technology, which is applied in the field of synthesis of pharmaceutical intermediates and drugs, can solve the problems of being difficult to adapt to market competitiveness, difficult to popularize production technology, dangerous in production process, etc., and achieve safe and reliable production process and easy reaction process. Control and reduce the effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

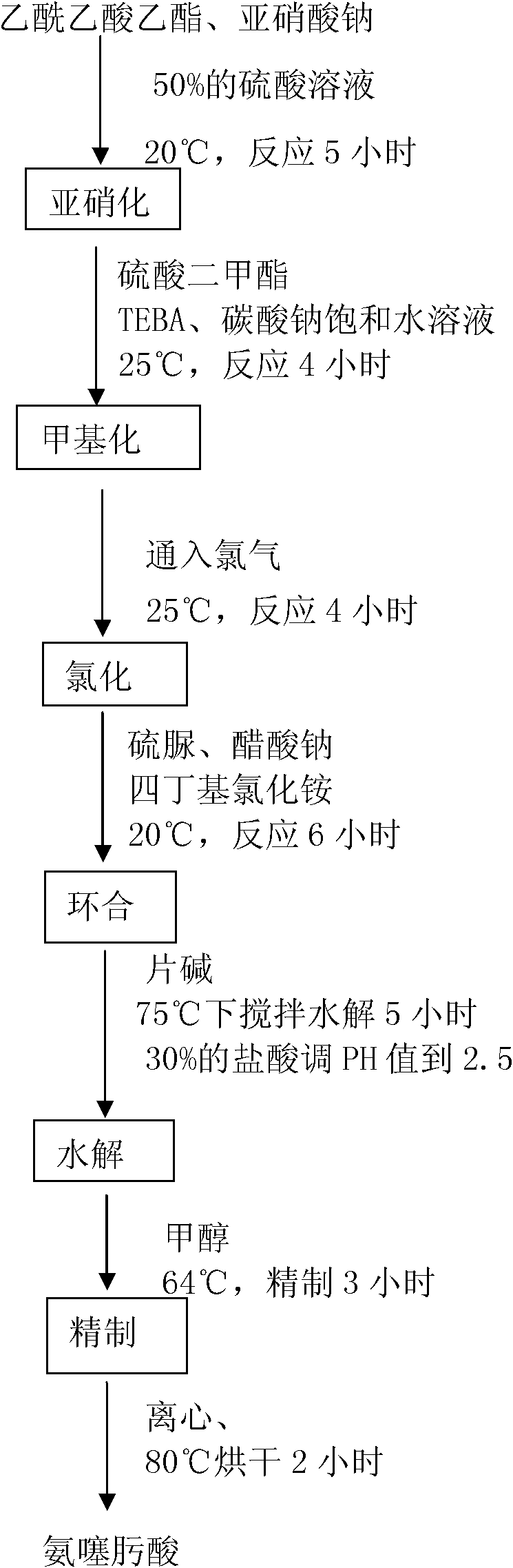

Image

Examples

Embodiment 1

[0018] A preparation method utilizing phase transfer to produce aminothiaxamic acid, the steps are:

[0019] A. Nitrosation: Put 130kg of ethyl acetoacetate into the reaction kettle, add 73.4kg of sodium nitrite and 200kg of water to make a solution, stir well; at 8 or 10 or 12 or 14 or 15 or 18 or 20 ℃ , add 100kg of sulfuric acid solution with a mass concentration of 50%, react for 3 or 5 or 6 or 7 or 8 hours, then divide the lower layer of the aqueous solution to obtain the product 2-hydroxime ethyl acetoacetate.

[0020] B. Methylation: Add 138.6kg of dimethyl sulfate, 0.5kg of phase transfer catalyst TEBA to 2-hydroxyxime ethyl acetoacetate, add dropwise the saturated solution prepared by 120kg of sodium carbonate and water, add about 0.5 or 1 or 2 or 3 or 4 or 5 hours to complete the addition, and then 16 or 19 or 23 or 25 or 28 or 30 ° C for 4 hours of heat preservation reaction, after the end of the reaction, the aqueous solution of the lower layer was separated,

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com