Sea moss-roasted flavour baked walnut and production method thereof

A production method and walnut technology, applied in the field of food, can solve the problems of poor taste and better release of aroma substances, and achieve the effects of rich taste, good economic benefits and good palatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

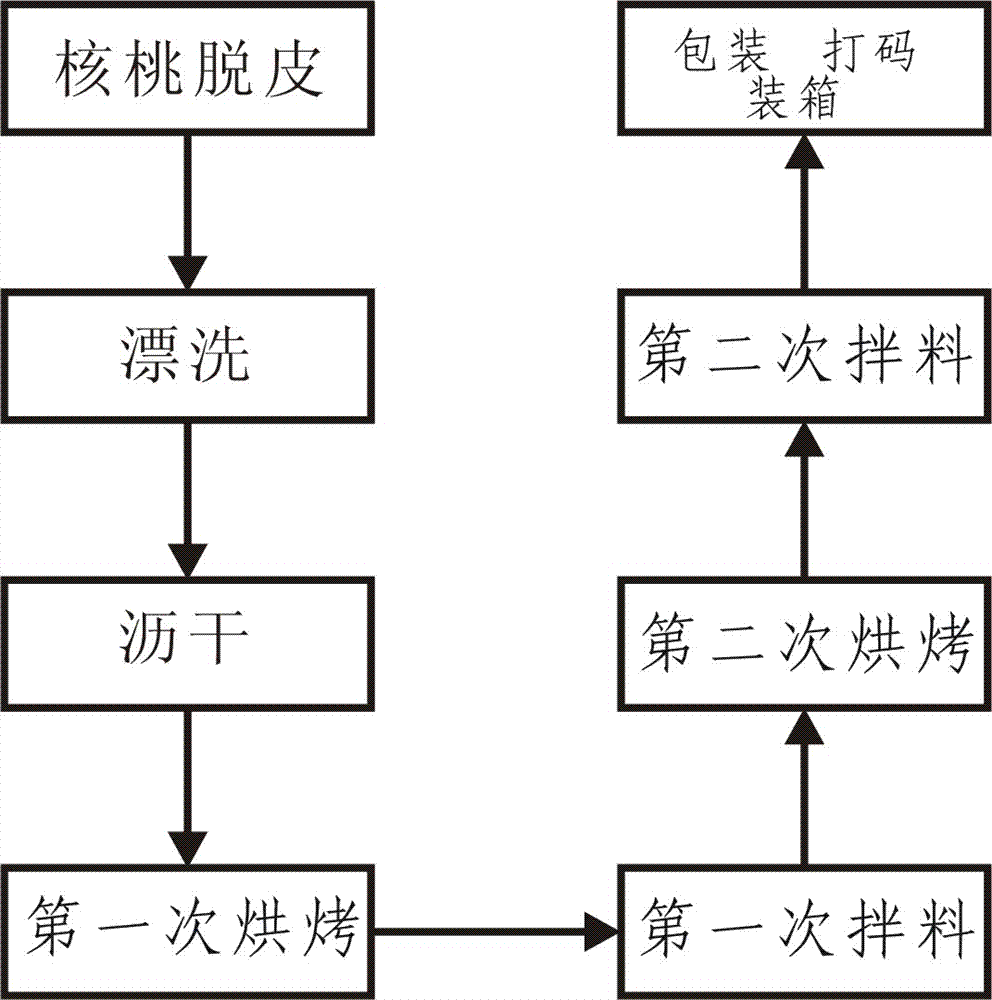

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: each raw material adopts following parts by weight in the present embodiment:

[0021] 73 parts of roasted walnuts, 1.5 parts of sugar powder, 0.25 parts of garlic powder, 0.95 parts of salt, 0.25 parts of monosodium glutamate, 0.27 parts of dry yeast powder, 8.0 parts of crushed peanuts, 0.66 parts of salt and pepper powder, 1.95 parts of butter, 6.3 parts of malt syrup, 0.14 parts of white pepper powder, 2.5 parts of seaweed powder essence, and 1.8 parts of barbecue powder essence.

[0022] Its production process is as follows:

[0023] Pretreatment of auxiliary materials and production of white sugar powder, because the white sugar particles are relatively coarse, which is not conducive to mixing materials, the white sugar should be ground into powder with a food grinder first, and then subdivided through a 60-mesh sieve. For the production of peanut crumbs, choose peanuts that have taken off their red coats, use a vibrating sieve to remove impurities ...

Embodiment 2

[0046] Embodiment 2: each raw material adopts following parts by weight in the present embodiment:

[0047] 76 parts of roasted walnuts, 1.7 parts of white sugar powder, 0.27 parts of garlic powder, 1.0 parts of table salt, 0.27 parts of monosodium glutamate, 0.30 parts of dry yeast powder, 9.0 parts of crushed peanuts, 0.68 parts of salt and pepper powder, 1.98 parts of butter, 6.9 parts of malt syrup, 0.16 parts of white pepper powder, 3.0 parts of seaweed powder essence, and 1.9 parts of barbecue powder essence.

[0048] The production method of this embodiment is the same as embodiment 1.

Embodiment 3

[0049] Embodiment 3: In the present embodiment, each raw material adopts the following parts by weight: 74.19 parts of roasted walnuts, 1.57 parts of white sugar powder, 0.26 parts of garlic powder, 0.98 parts of table salt, 0.26 parts of monosodium glutamate, 0.28 parts of dry yeast powder, crushed peanuts 8.78 parts, 0.67 parts of salt and pepper powder, 1.96 parts of butter, 6.52 parts of malt syrup, 0.15 parts of white pepper powder, 2.56 parts of seaweed powder essence, and 1.86 parts of barbecue powder essence.

[0050] The production process of this embodiment is the same as that of embodiment 1.

[0051] In each of the above-mentioned embodiments: the roasted walnuts are obtained from high-quality walnuts purchased by our company in Chaotian District, Guangyuan City, and then processed by shelling and roasting. Chaotian walnuts are well-known throughout the country based on the unique geographical climate of the Chaotian area. Chaotian District is located in the centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com