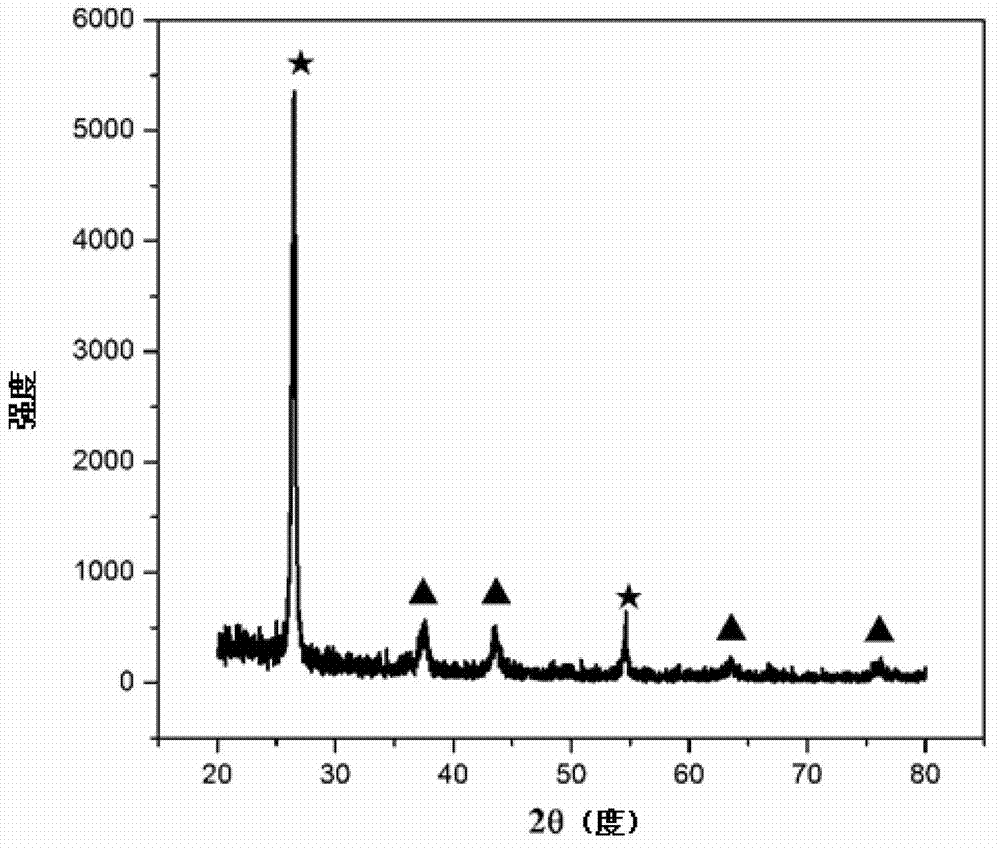

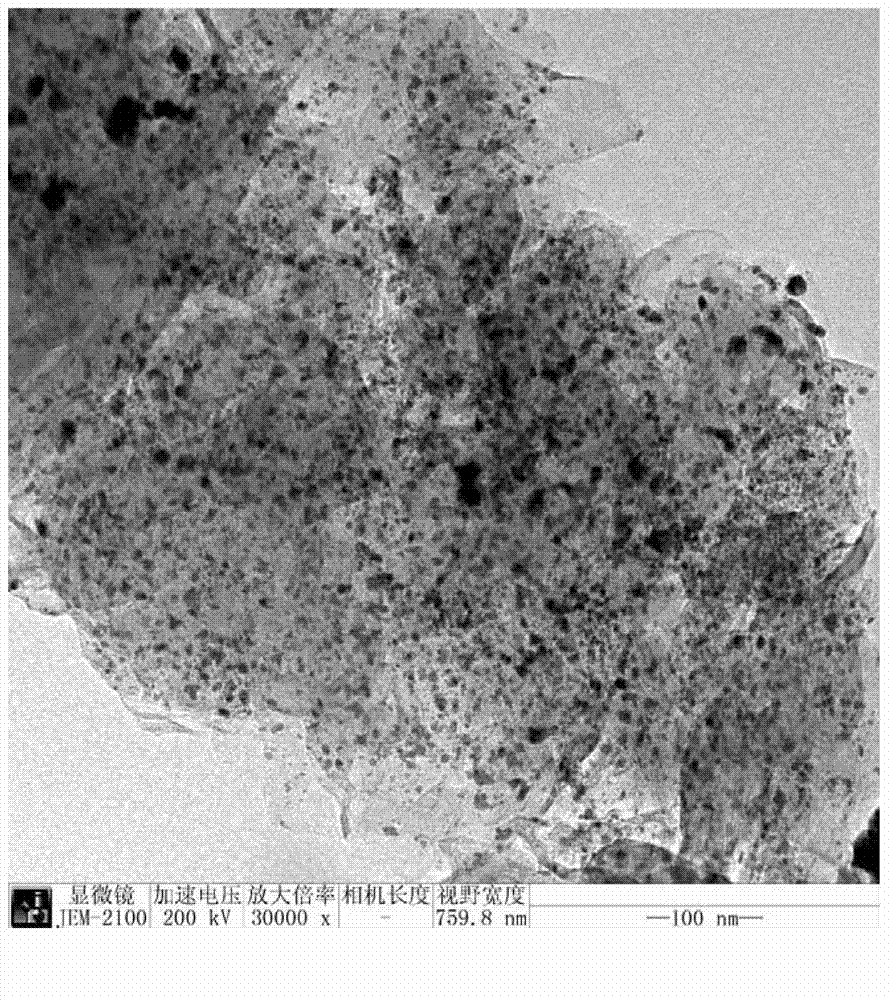

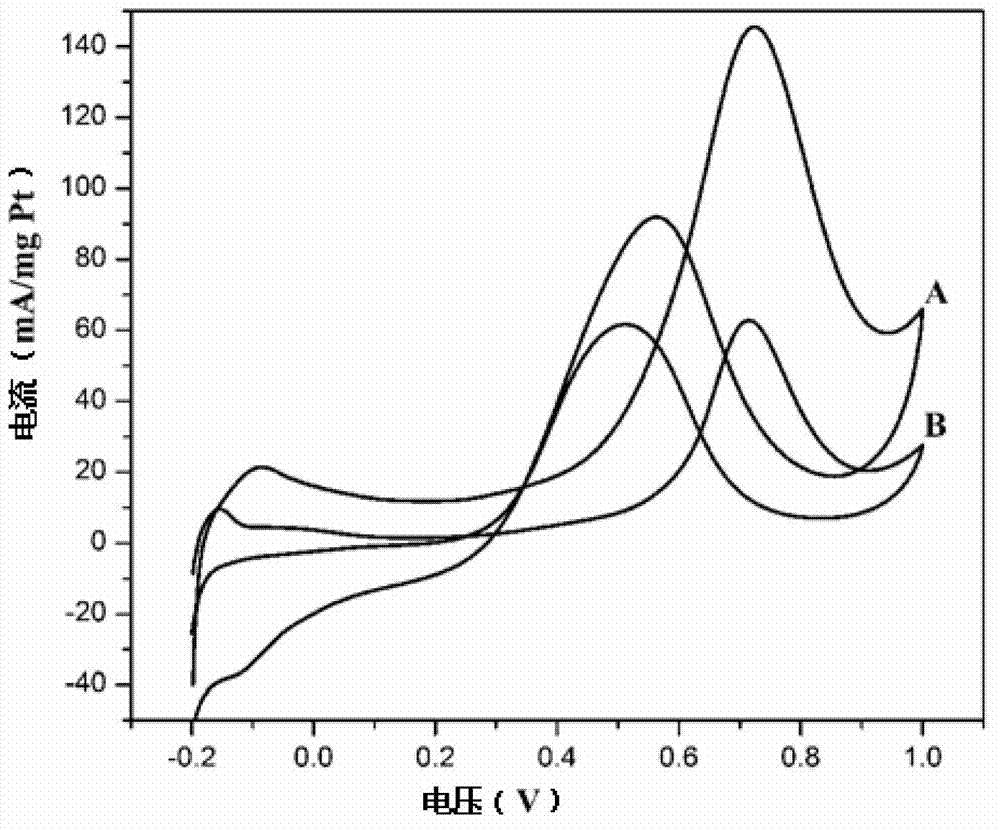

Method for loading nitride to graphite nano-sheet and application of graphite nano-sheet

A nanosheet and nitride technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of high production cost, easy agglomeration, large particle size, etc., and achieve low cost, reaction Mild conditions, evenly distributed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0027] Specific embodiment one: the method for loading nitride on the graphite nano flakes in this embodiment is carried out according to the following steps:

[0028] 1. Weigh 0.3-6 parts of tungsten source, molybdenum source or vanadium source, 1 part of expandable graphite, 0.05-0.6 parts of surfactant and 50-100 parts of solvent in parts by weight;

[0029] 2. Put the expandable graphite into the high temperature furnace and continuously feed N 2 Or use Ar gas as a protective gas, then heat up to 700°C to 1100°C, heat treatment for 1min to 10min, and then cool to room temperature to obtain expanded graphite;

[0030] 3. Dissolve the tungsten source, molybdenum source or vanadium source and surfactant weighed in step 1 in the solvent measured in step 1, and ultrasonicate for 15 minutes under the condition of ultrasonic power of 100W to obtain a uniformly mixed precursor;

[0031]4. Put the expanded graphite prepared in step 2 into a vacuum filtration device, and inject the...

specific Embodiment approach 2

[0040] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, 3 parts by weight of tungsten source, molybdenum source or vanadium source, 1 part of expandable graphite, and 0.3 parts of surfactant are weighed and 60 parts of solvent. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0041] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 2, the temperature is raised to 800° C. to 1000° C., and the heat treatment is performed for 3 minutes to 8 minutes. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com