Arc voltage track pulse submerged-arc welding control method, control circuit and welding machine

A technology of tracking pulses and control methods, which is applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve problems such as harsh working conditions, small installation space, and difficult control, and achieve low implementation costs, simple control circuits, and good performance. The effect of external characteristic output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0038] Firstly, it is determined that the present invention relates to an arc voltage tracking pulse submerged arc welding, which belongs to the technical field of submerged arc welding equipment.

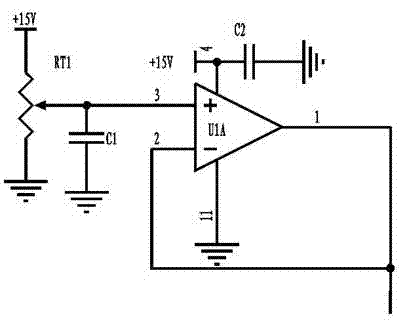

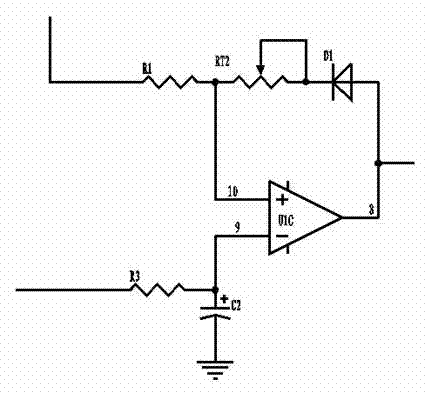

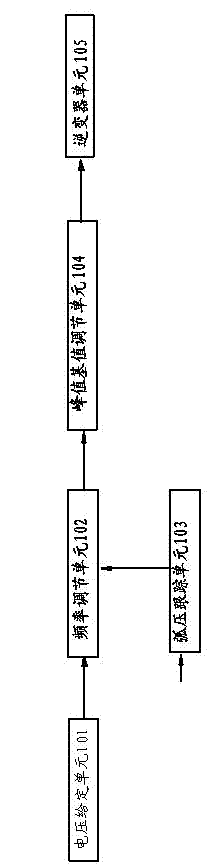

[0039] The invention provides an arc voltage tracking pulse submerged arc welding control method. The arc voltage tracking pulse submerged arc welding control method adopts the arc voltage tracking mode to sample the output voltage, and realizes the control of the pulse current according to the change of the arc voltage.

[0040]In the technical solution of the present invention: the arc voltage tracking pulse submerged arc welding control method includes the steps: A: compare the reference voltage signal superimposed on the output pulse current with the output arc voltage signal, and output a high-low variation signal according to the comparison result The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com