Shirt shell fabric

A technology for fabrics and shirts, applied in the field of shirt fabrics, can solve the problems of poor water absorption and moisture absorption, difficult to popularize and use, poor elongation, etc., and achieve good air permeability, excellent drape and elongation recovery, and simple production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

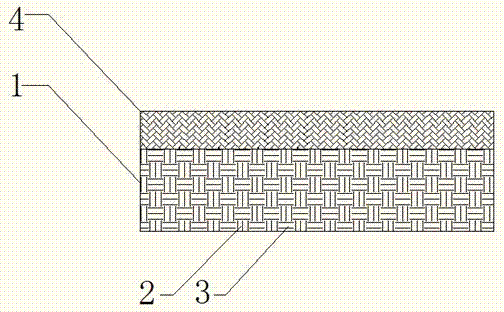

[0010] see figure 1 , a kind of shirting fabric, comprises fabric base layer 1, and described fabric base layer 1 comprises warp yarn 2 and weft yarn 3, and described fabric base layer 1 surface is provided with anti-wrinkle layer 4, and between described fabric base layer 1 and anti-wrinkle layer 4 passes water-based polyurethane Adhesive compounded together.

[0011] The warp yarn is blended with tussah silk and soybean fiber, and the weft yarn is bamboo fiber. The soybean fiber has excellent properties such as soft touch, soft glossy cotton and good skin affinity, and the bamboo fiber has good air permeability, Instant water absorption, strong wear resistance and good dyeability, among which the blending ratio of tussah silk and soybean fiber is 30%:70%.

[0012] The anti-wrinkle layer is made of blended PTT fiber and polyester, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com