Cementing material with strength grade of above 200MPa and preparation method thereof

A technology of cementitious materials and strength grades, which is applied in the field of building materials, can solve problems such as poor thermal stability, high cost, and poor durability, and achieve the effects of popularizing value, increasing strength, and improving concrete fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A cementitious material with a strength level above 200MPa proposed by the present invention uses silicate clinker as a component raw material, mixes a certain proportion of the compounded mixture to form it, puts it into a curing box for curing, and takes out the colloidal sand for testing after 28 days. The blocks are subjected to compression tests, and the strength exceeds 210MPa.

[0018] Introduce the embodiment of the present invention below:

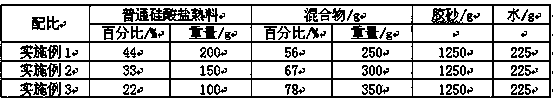

[0019] The ingredients (in grams) are as follows:

[0020]

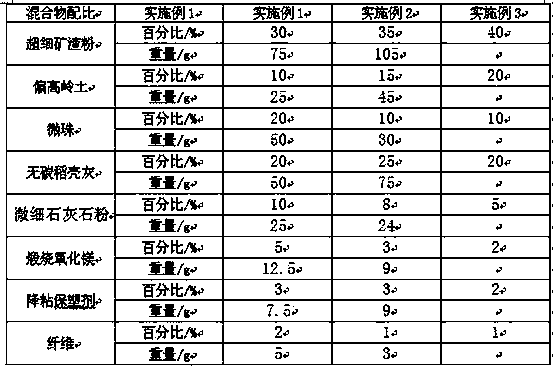

[0021] The proportions of each component in the mixture of the three embodiments are as follows:

[0022]

[0023] Among the above-mentioned viscosity-reducing and plastic-preserving agents, there are 75 parts of zeolite powder and 25 parts of sodium gluconate.

[0024] Pour cement, various ingredients, and plastic sand into the plastic sand mixer one after another, stir and vibrate, and then put them in the curing box for curing. After demoulding for 24 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com