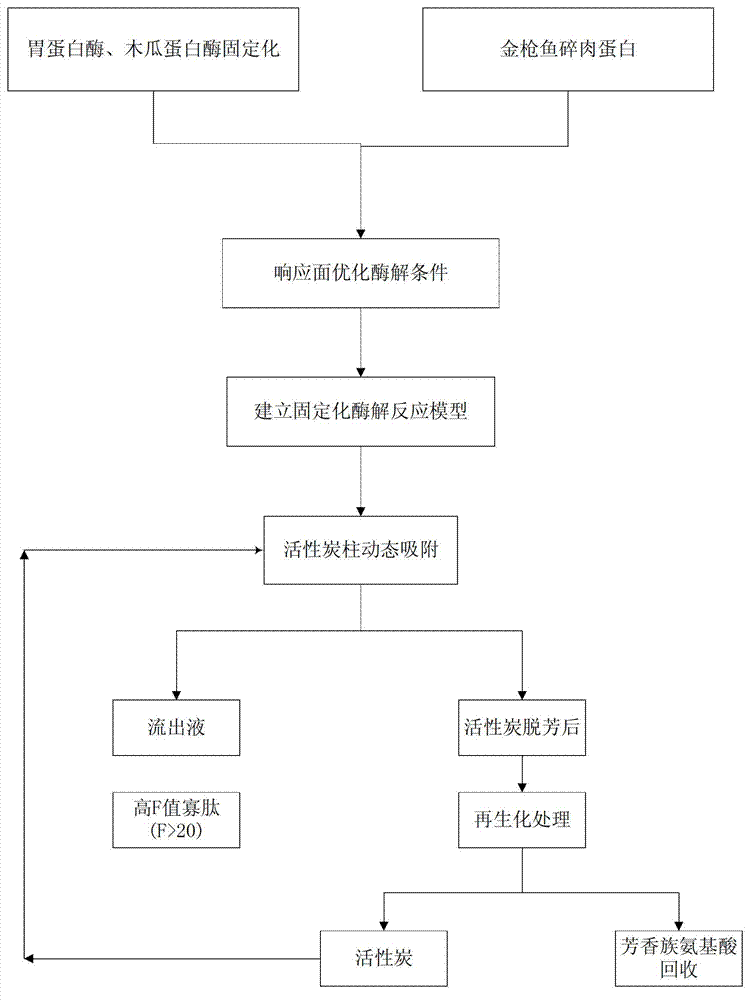

Preparation method of high-F-value tuna oligopeptide

A technology of tuna and oligopeptides, applied in the direction of peptide preparation methods, chemical instruments and methods, peptides, etc., can solve the problems of multi-activated carbon, difficult regeneration of activated carbon, and limited elution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of high F value tuna oligopeptide comprises the following steps:

[0034] Pretreatment: Weigh 50g of thawed tuna mince, homogenize it with a homogenizer for two minutes until there are no large pieces of fish, then add distilled water according to w / v=1:7, put it in the reactor, 35°C insulation;

[0035] The first step of enzymatic hydrolysis: adjust the pH of the reaction solution to 2.0 with 6mol / L HCl solution, add pepsin at 800U / g, place in a 35°C shaking water bath for 4 hours, and use 6mol / L HCl every half hour Adjust the pH value of the solution once, so that the enzymolysis solution is always at pH 2.0 for enzymolysis; adjust the temperature of the reactor to 95°C to inactivate the enzyme for 15 minutes, adjust the pH to neutral, cool to room temperature, and then suction filter, and the filtrate is set aside;

[0036] The second step of enzymatic hydrolysis: take the filtrate of the first step of enzymatic hydrolysis, add actinase accord...

Embodiment 2

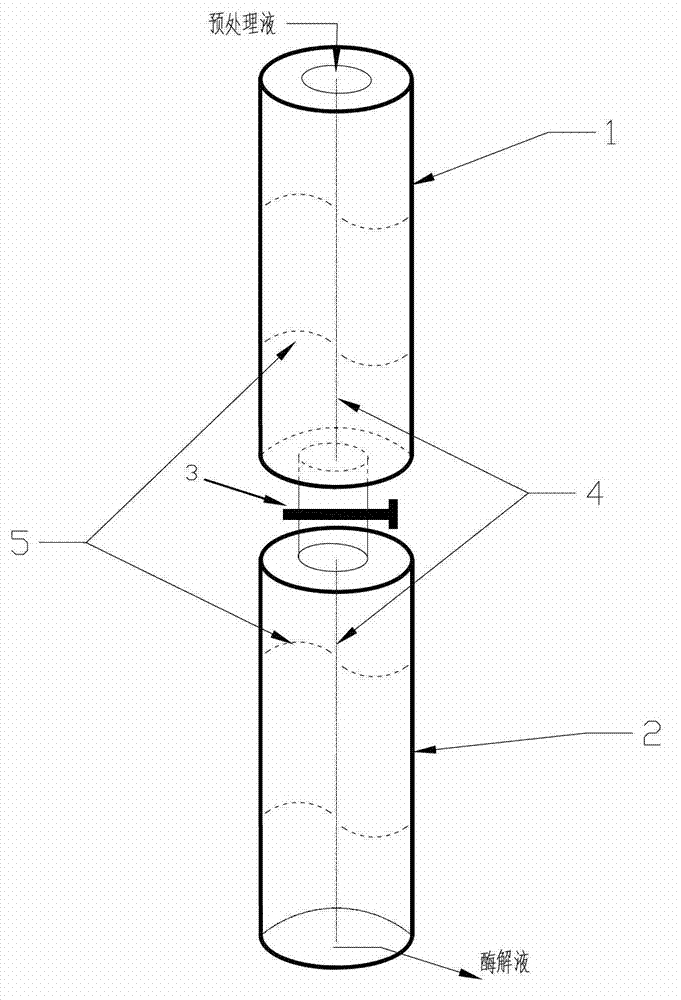

[0041] Different from Example 1, this example uses an immobilized enzyme reactor.

[0042] Immobilized enzyme preparation:

[0043] Weigh a certain amount of chitosan, dissolve it completely with 2% acetic acid solution, put the prepared chitosan gel in 1:3 90% ethanol solution with a syringe, coagulate for 2 hours, add 5% glutaraldehyde, start Vibrate at 150 rpm for 1 hour with a magnetic stirrer, and wash thoroughly with deionized water until there is no residual glutaraldehyde.

[0044] Add a certain amount of pepsin solution prepared by lactic acid-sodium lactate with pH=3.0 to the cross-linked carrier, cross-link in a refrigerator at 4°C for 10 h, wash with distilled water, and filter with Buchner funnel to obtain immobilized enzyme.

[0045] A certain amount of papain solution prepared by distilled water was added to the cross-linked carrier, cross-linked in a refrigerator at 4° C. for 10 h, washed with distilled water, and filtered through a Buchner funnel to obtain...

Embodiment 3

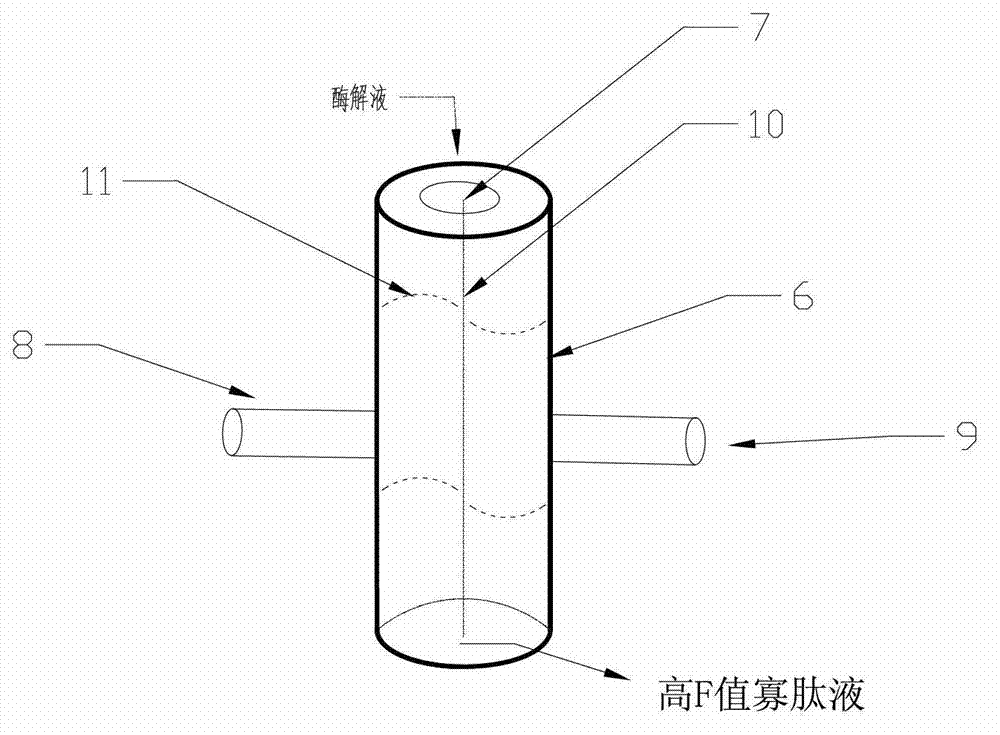

[0055] The difference from Example 2 is that this example uses an adsorption reactor instead of an activated carbon adsorption column.

[0056] Put the activated carbon into the rotating interlayer. When adsorbing, turn on the pump one, set the pressure to 0.04Mpa, and the adsorption temperature at 40°C. The enzymolysis solution enters the activated carbon column. Turn on the blade to make it fully contact with the activated carbon, and turn on the left pump at the same time. 2. Set the pressure to 0.02Mpa, set the desorption temperature to 15°C, and let the desorption liquid flow into the rotating interlayer. Because of the low pressure, it will not enter the enzymatic hydrolysis liquid, and the desorption liquid will desorb the aromatic amino acids adsorbed by activated carbon. Down, turn on the pump three on the right side, set the pressure to -1000Pa, and let the desorption liquid flow out. The adsorption pipeline and the analytical pipeline are relatively independent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com