Directly-buried steam pipeline for long-distance transportation

A technology of steam and direct burial, which is applied in the direction of pipeline protection, pipeline protection through heat insulation, pipeline anticorrosion/rust protection, etc. It can solve problems such as accidental damage to pipelines, affecting the operation of pipeline networks, and broken water ingress, etc., to achieve heat transfer coefficient Small, improve water permeability, reduce the effect of heat flow leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

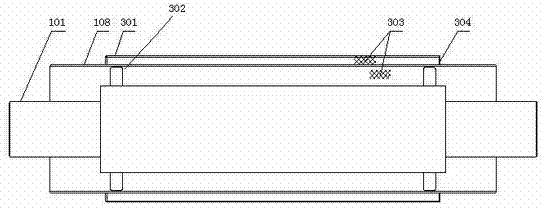

[0024] A directly buried steam pipeline for long-distance transportation, which includes: a lower drain joint 4, a movable inner and outer fixed support 2, a tee 5, a straight pipe with a sliding support 1, a compensator 3 and an elbow 6, and the arrangement sequence is drain Section 4. Displaceable internal and external fixed support 2, tee 5, straight pipe with sliding bracket 4, compensator 3, displaceable internal and external fixed support 2 and elbow 6.

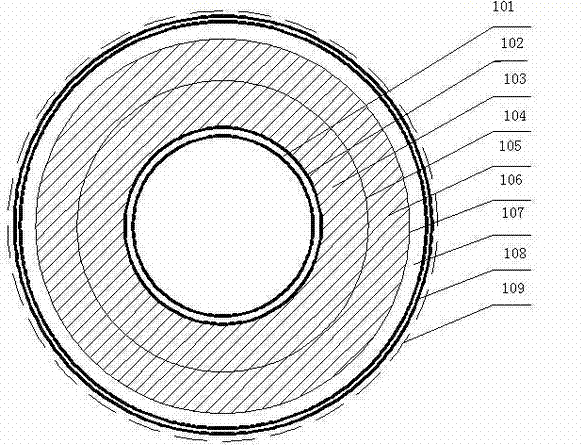

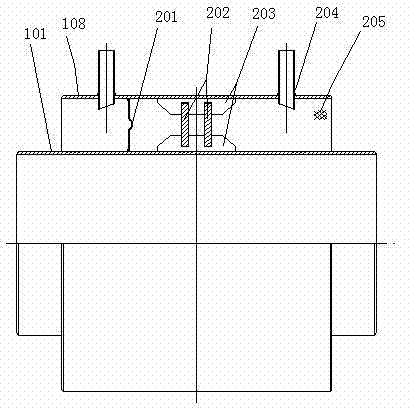

[0025] The straight pipe with sliding support includes a working steel pipe 101 for long-distance transport of high-temperature medium and an outer protective pipe 108. The outer protective pipe 108 is composed of an outer protective steel pipe and its outer side alternately composited chopped fiber-resin and two-dimensional untwisted glass The three-dimensional glass fiber reinforced plastic of fiber grid cloth is formed, and between working steel pipe 101 and outer protective pipe 108, be provided with multi-screen ins...

Embodiment 2

[0031] A directly buried steam pipeline for long-distance transportation, which includes: a lower drain joint 4, a movable internal and external fixed support 2, a tee 5, a straight pipe with a sliding support 1, a compensator 3 and an elbow 6, and the arrangement sequence is as follows: Displacement internal and external fixed support 2, hydrophobic joint 4, compensator 3, straight pipe with sliding support 1, movable internal and external fixed support 2, straight pipe with sliding support 1, elbow 6, straight pipe with sliding support 1 and displaceable Internal and external fixed support 2.

[0032] The straight pipe with sliding support includes a working steel pipe 101 for long-distance transport of high-temperature medium and an outer protective pipe 108. The outer protective pipe 108 is composed of an outer protective steel pipe and its outer side alternately composited chopped fiber-resin and two-dimensional untwisted glass The three-dimensional glass fiber reinforced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com