Air cooling heat exchange device for heat pipe energy transporting system

A technology of heat exchange device and heat pipe condenser, which is applied in the field of energy-saving and environmentally friendly air-cooled heat exchange devices, high-efficiency, air-cooled heat exchange devices, can solve the problems of low heat exchange efficiency and air temperature rise, and achieve heat exchange efficiency. Improve, enhance heat exchange effect, increase the effect of ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

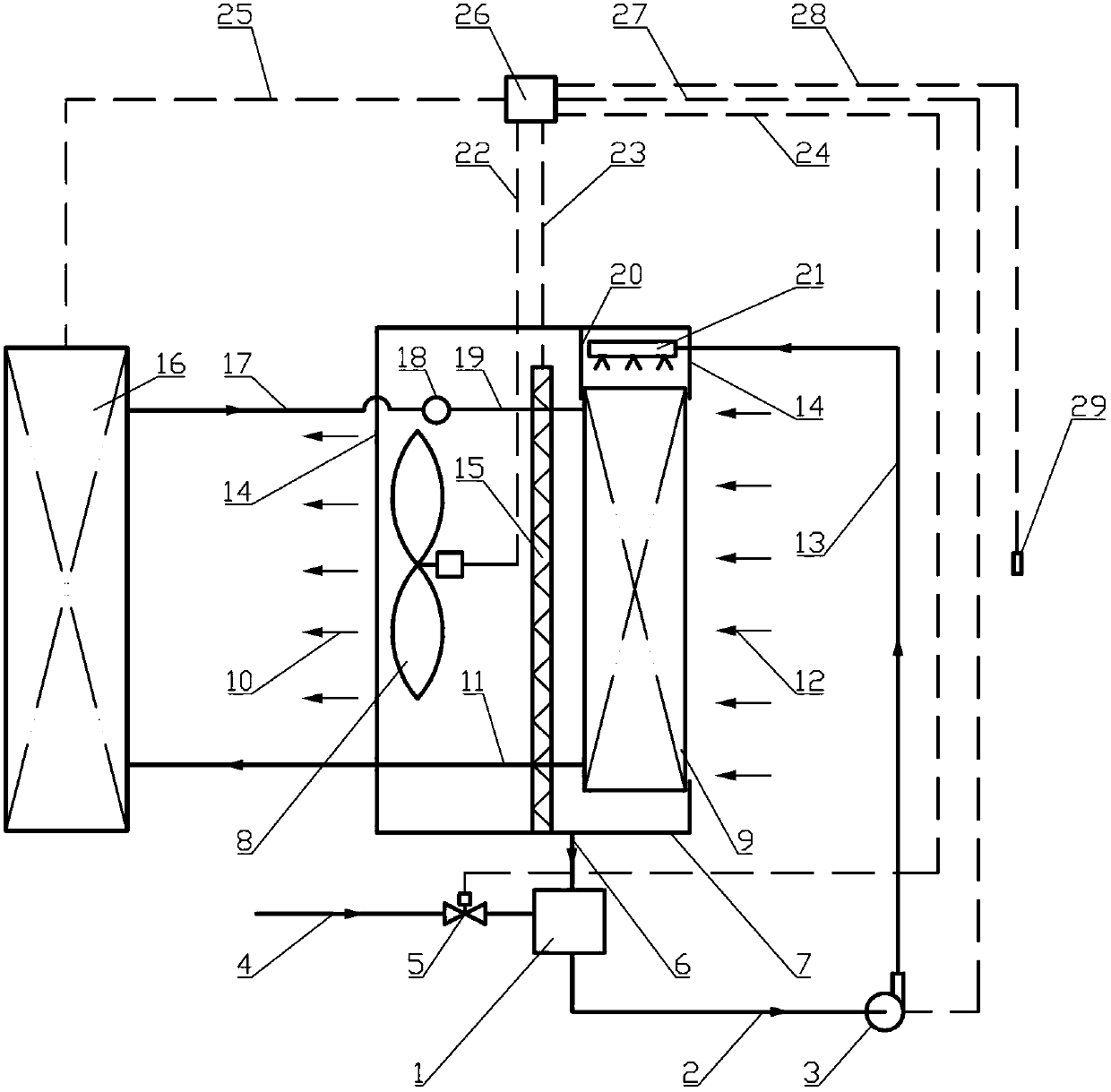

[0019] The structural principle and working flow schematic diagram of the first high-efficiency air-cooled heat exchange device suitable for the heat pipe energy transport system involved in this embodiment is as follows: figure 1 As shown, it includes a supplementary water supply and control subsystem composed of a water tank 1, a water supply pipe 4 and a water control valve 5; Plate 15, water tray 7 and water return pipe 6 are connected to form a circulating water supply and distribution subsystem; heat pipe evaporator combination 16, heat pipe gaseous (gas-liquid two-phase flow) working medium feeding pipe 17, heat pipe gaseous (gas-liquid two-phase flow) phase flow) working medium distributor 18, the heat pipe gaseous (gas-liquid two-phase flow) working medium equalizing pipe 19, the heat pipe condenser 9 and the heat pipe liquid working medium return pipe 11 are connected to form the heat pipe body subsystem; the air inlet 12, the heat pipe Condenser 9, outer sealing she...

Embodiment 2

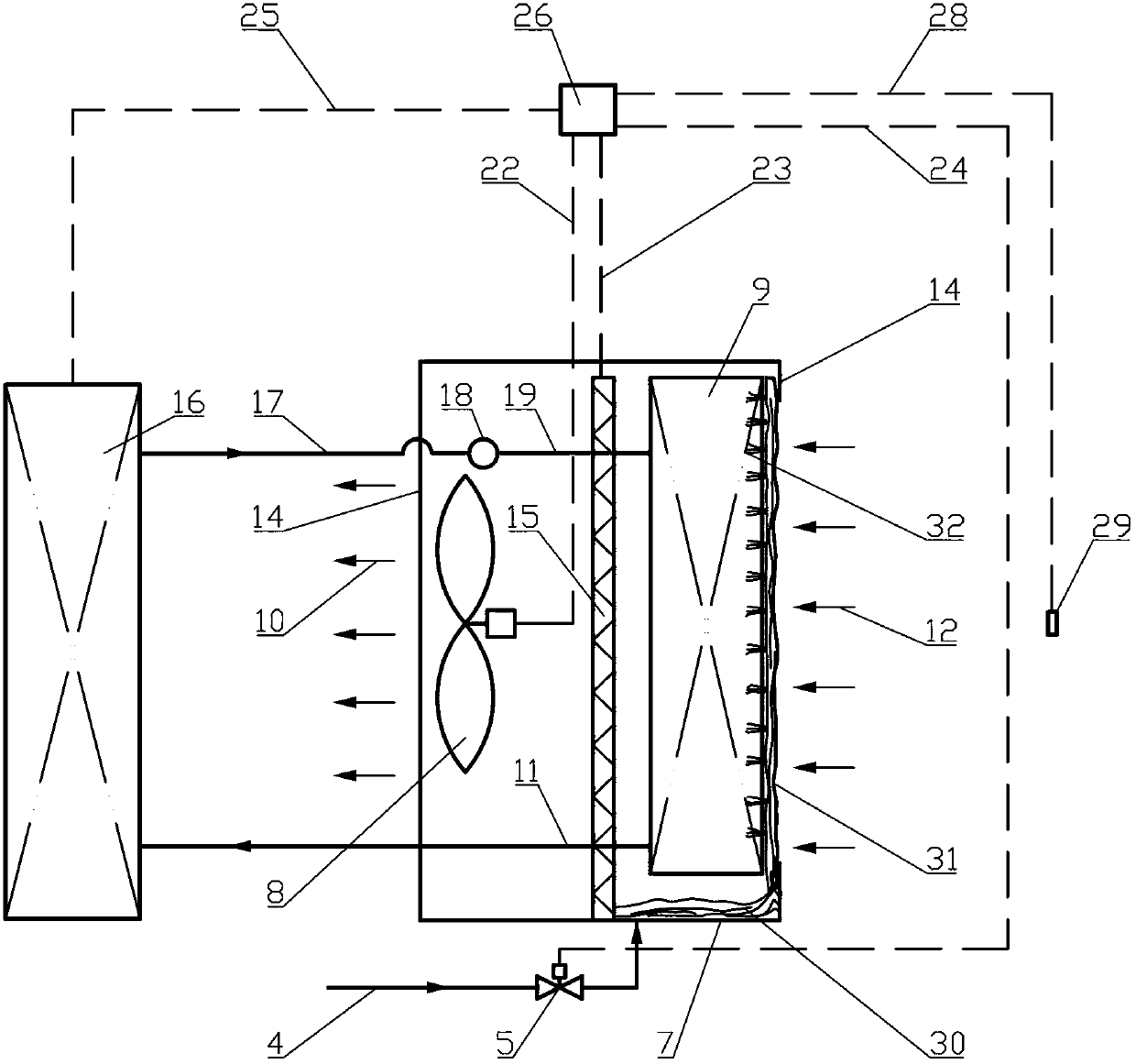

[0021] The structural principle and working flow diagram of the second air-cooled heat exchange device involved in this embodiment are as follows: figure 2 As shown, it includes a supplementary water supply and control subsystem composed of a water receiving tray 7, a water supply pipe 4 and a water control valve 5; Circulating water supply and distribution subsystem formed by connecting water tray 7; heat pipe evaporator and other combinations 16, heat pipe gaseous (gas-liquid two-phase flow) working medium feeding pipe 17, heat pipe gaseous (gas-liquid two-phase flow) working medium distribution 18, the heat pipe gaseous (gas-liquid two-phase flow) working medium equalizing pipe 19, the heat pipe condenser 9 and the heat pipe liquid working medium return pipe 11 are connected to form the heat pipe body subsystem; the air inlet 12, the heat pipe condenser 9, and the outer sealing shell 14. The air flow and treatment subsystem composed of the water baffle 15, the fan 8 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com