Air cooling heat exchange device for heat pipe energy transporting system

A technology of heat exchange device and heat pipe condenser, which is applied in the direction of heat exchanger types, indirect heat exchangers, fixed conduit components, etc., can solve the problems of low heat exchange efficiency and rising air temperature, and achieve improved heat exchange efficiency and Enhanced thermal effect, efficient deep cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

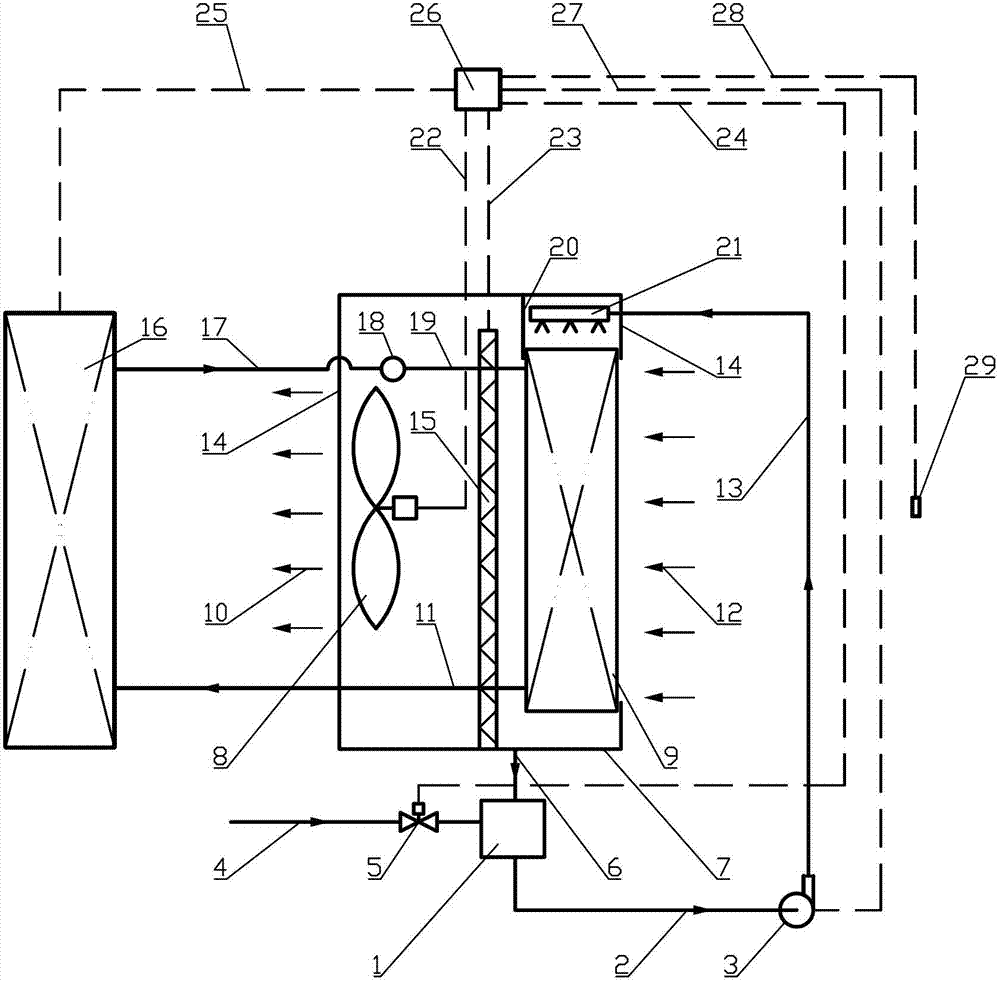

Embodiment 1

[0019] The structure principle and working flow diagram of the first high-efficiency air-cooled heat exchange device suitable for the heat pipe energy transport system involved in this embodiment are as follows: figure 1 As shown, it includes a supplementary water supply and control subsystem composed of a water tank 1, a supplementary water pipe 4 and a water control valve 5; The plate 15, the water receiving tray 7 and the return pipe 6 are connected to form a circulating water supply and distribution subsystem; the heat pipe evaporator combination 16, the heat pipe gaseous (gas-liquid two-phase flow) working medium feeding pipe 17, the heat pipe gaseous (gas-liquid two-phase flow) Phase flow) working medium distributor 18, heat pipe gaseous (gas-liquid two-phase flow) working medium equal share pipe 19, heat pipe condenser 9 and heat pipe liquid working medium return pipe 11 connected to form the heat pipe body subsystem; Condenser 9, outer sealing shell 14, inner sealing p...

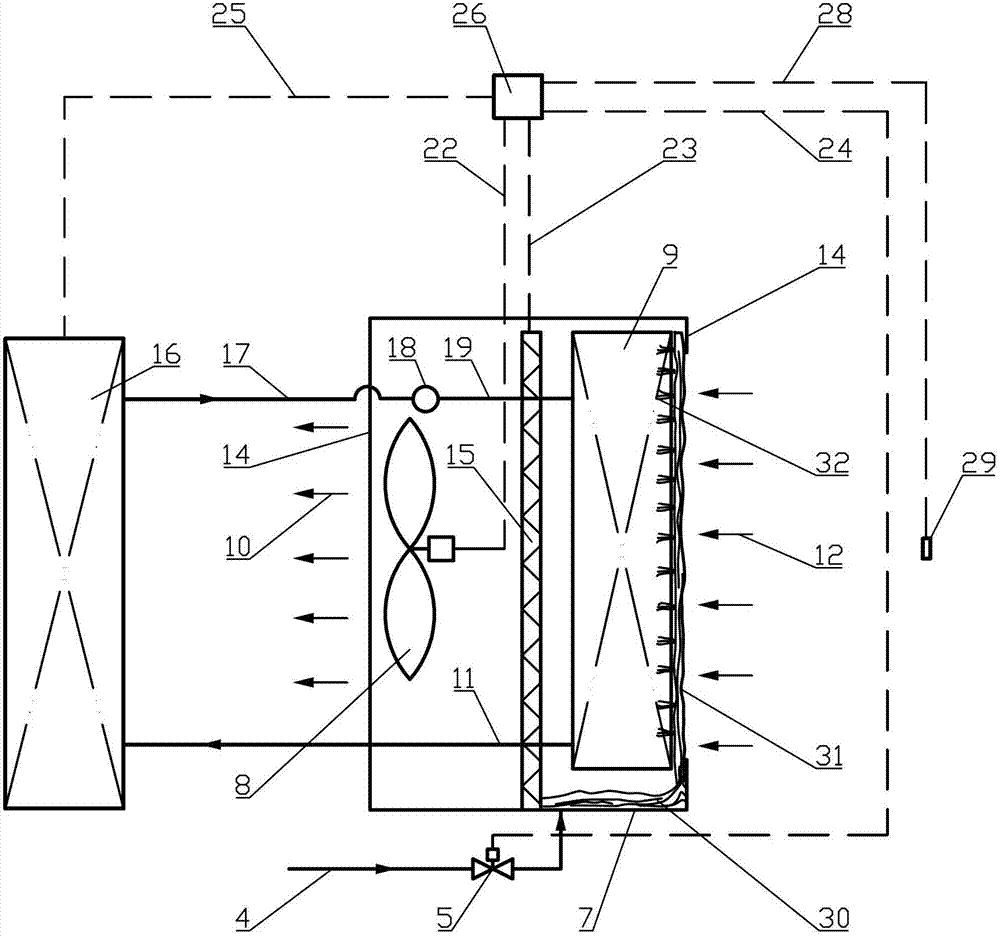

Embodiment 2

[0021] The structural principle and working flow diagram of the second type of air-cooled heat exchange device involved in this embodiment are as follows figure 2 As shown, it includes a supplementary water supply and control subsystem composed of a water receiving tray 7, a supplementary water pipe 4 and a water control valve 5; The circulating water supply and distribution subsystem formed by the connection of the water receiving tray 7; composed of a combination of heat pipe evaporators 16, heat pipe gaseous (gas-liquid two-phase flow) working medium feeding pipe 17, heat pipe gaseous (gas-liquid two-phase flow) working medium distribution 18, heat pipe gaseous (gas-liquid two-phase flow) working medium equal share pipe 19, heat pipe condenser 9 and heat pipe liquid working medium return pipe 11 are connected to form the heat pipe body subsystem; 14. The air flow and processing subsystem formed by the communication between the water baffle 15, the fan 8 and the exhaust 10;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com