Method for replacing corn ingredients in pig feed

A pig feed, corn technology, applied in animal feed, animal feed, application and other directions, can solve the problems of natural corrosion or burning, waste of resources, damage to the structure and other problems, to improve daily weight gain, low reaction temperature, enzymatic hydrolysis reaction activity-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The wheat straw was shredded into pieces with a length of 2 cm, a width of 1 cm and a thickness of 2 cm, and the wheat straw was mechanically activated by a three-dimensional mill. The activation time was 3 minutes, and the grain size of the wheat straw was 250 mesh. The reduced sugar of the activated wheat straw is measured by conventional measurement methods in the field of feed, which is 2.5 times that of the raw material before activation; , the surface active groups of straw fiber increased significantly, and the cation exchange capacity was significantly enhanced, which was 1.5 times that of the raw material before activation. Twelve times that of the previous raw material, the water diffusibility is significantly enhanced. The prepared mechanically activated wheat straw is packaged in a woven bag with an inner film bag, sealed and stored in a ventilated, cool and dry place.

Embodiment 2

[0018] Weigh 40kg of the mechanically activated wheat straw product obtained in Example 1, 960kg of full-price feed for growing pigs (T312) produced by Shanghai Xinnong Feed Co., Ltd. In addition to the components, the crushing particle size of other feed components is 40 mesh. Mix the above-mentioned feed components for 3 minutes with a mixer, then pack them in woven bags with an inner film, and store them in a ventilated, cool and dry place after sealing.

Embodiment 3

[0020] Weigh 60 kg of the mechanically activated wheat straw product obtained in Example 1, 940 kg of full-price feed for fattening pigs (T313) produced by Shanghai Xinnong Feed Co., Ltd. Except for the corn component, the crushing particle size of other feed components is 30 mesh. Mix the above-mentioned feed components for 3 minutes with a mixer, then pack them in woven bags with an inner membrane, and store them in a ventilated, cool and dry place after sealing.

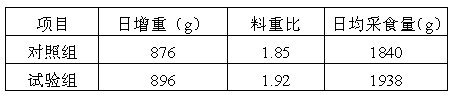

[0021] Illustrate effect of the present invention below by contrast test:

[0022] The specific arrangement of the test is as follows:

[0023] (1) Test animals

[0024] The body weight of 35kg (±0.5kg) long × large binary hybrid meat pigs (a binary hybrid of Landrace and Large White pigs) was selected.

[0025] Trial date and location

[0026] From August 25th to September 27th, 2011 at Xinnong Nanhui Pig Farm in Shanghai.

[0027] (2) Experimental design and diet

[0028] In this experiment, single ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com