Function-shared three-composite-layer laminated flameproof fabric, preparation technology and application

A technology of function sharing and fireproof cloth, which is applied in the field of composite fireproof fabrics, can solve problems such as burns or burns, and achieve the effect of simple processing and reasonable functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

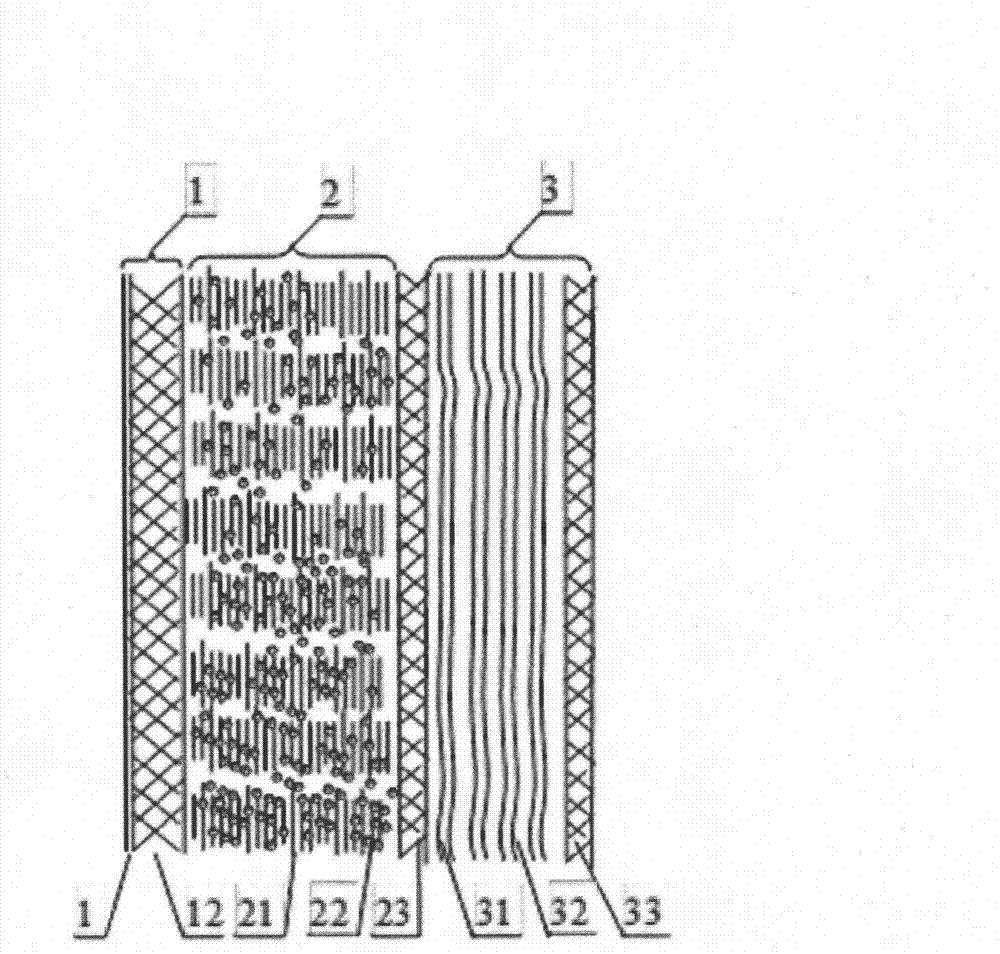

Image

Examples

Embodiment 1

[0039] The fireproof cloth laminated with three composite layers adopts the function sharing of the present invention. Among them, the reflective heat insulation layer is made of 6μm metal aluminum foil (the weight of the square meter is 15.7g / m 2 ) and basalt fiber reinforced base fabric (thickness 0.26mm, square meter weight 212.8g / m 2 ) compounded by adhesive; the natural thickness of the heat consumption and temperature-limiting layer is 2.32mm, and the weight per square meter is 318.2g / m 2 ;The natural thickness of the thermal insulation comfort layer is 0.59mm, and the weight per square meter is 194.6g / m 2 . The final compressed thickness of the fireproof cloth is 2.76mm, and the square meter weight is 821.5g / m 2 , the outer side is kept under the environment of 1000 ℃ high temperature and strong heat flow for 8 minutes, and the inner temperature can be kept below 45 ℃.

Embodiment 2

[0041] The fireproof cloth laminated with three composite layers adopts the function sharing of the present invention. Among them, the reflective heat insulation layer is made of 9μm metal aluminum foil (the weight of the square meter is 20.4g / m 2 ) and glass fiber reinforced base fabric (thickness 0.23mm, square meter weight 196.9g / m 2 ) compounded by adhesive; the natural thickness of the heat consumption and temperature-limiting layer is 2.51mm, and the weight per square meter is 325.1g / m 2 ;The natural thickness of the thermal insulation comfort layer is 0.52mm, and the weight per square meter is 188.3g / m 2 . The final compressed thickness of the fireproof cloth is 2.84mm, and the square meter weight is 803.6g / m 2 , the outer side is kept under 800°C open flame high temperature and strong heat flow environment for 10 minutes, and the inner temperature can be kept below 50°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com