Device for generating hydrogen through powder hydrolysis

A technology of hydrogen production and powder by hydrolysis, which is applied in the production of hydrogen, etc., can solve the problems of reducing the life of hydrophobic and breathable membranes, poor hydrogen purity and dryness, and reduced life, so as to increase practicability and reliability and ensure dryness and purity, prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

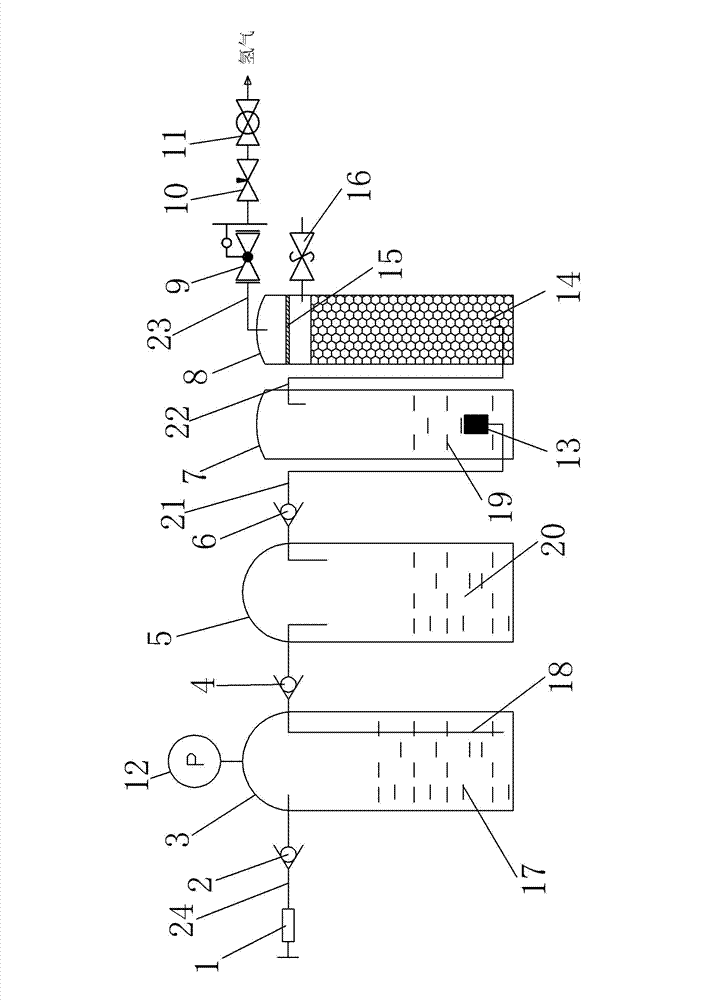

[0011] See figure 1 , which includes a powder raw material solution tank 3 and a reaction tank 5. The powder raw material solution tank 3 is equipped with a raw material solution 17. The raw material solution 17 is specifically formed by dissolving hydrogen production powder in water. The hydrogen production powder is specifically sodium borohydride powder. The powder raw material solution The bottom of tank 3 is connected to the top inlet of reaction tank 5 by liquid pipeline 18, and catalyst 20 is housed in reaction tank 5, and the top outlet of reaction tank 5 is communicated with the porous medium filter head 13 of water filtration cooling tank 7 by outlet pipeline 21 Inlet, liquid water 19 is housed in the water filter cooling tank 7, the porous media filter head 13 is immersed in the liquid water 19, the upper outlet of the water filter cooling tank 7 is connected to the lower inlet of the dry filter 8 through the pipeline 22, and the dry filter 8 The lower part of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com