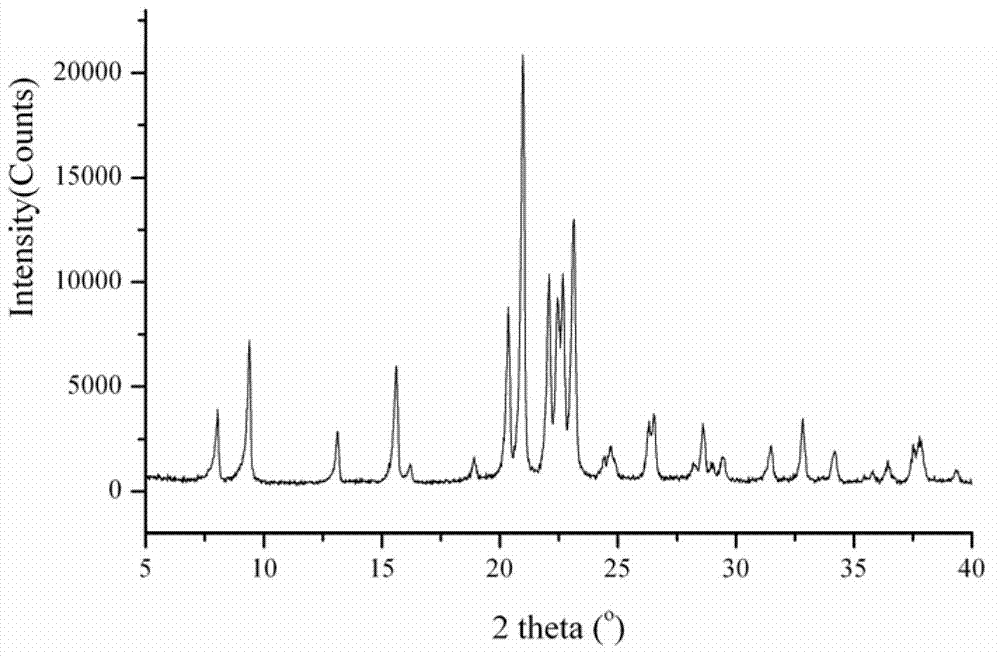

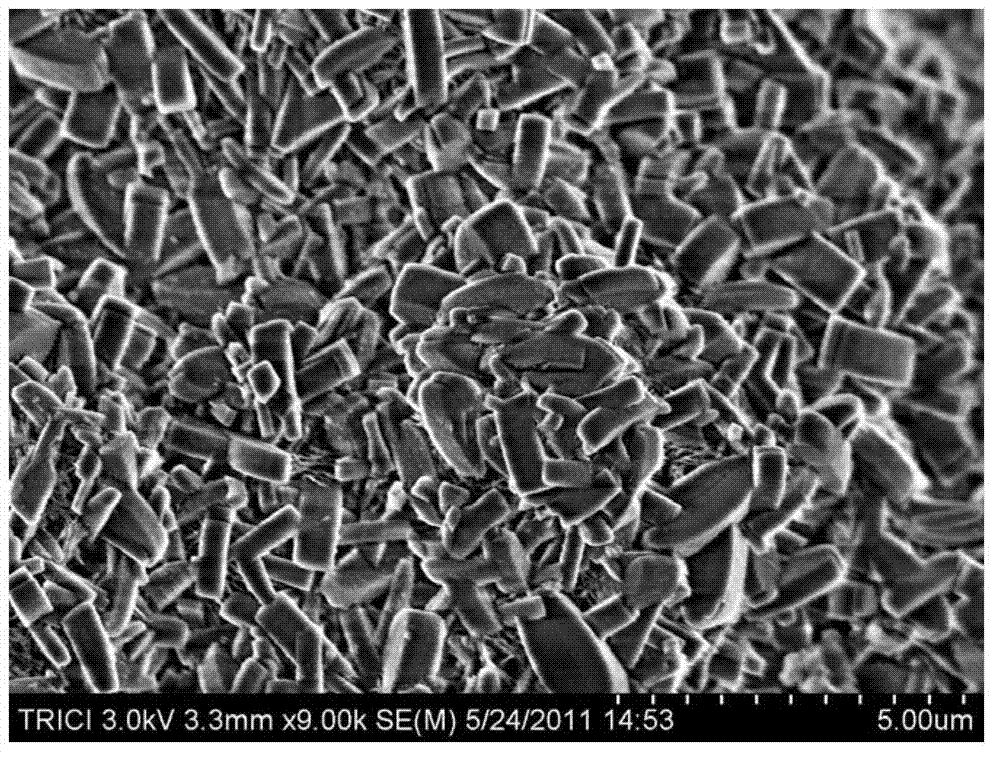

Method for synthesizing silicoaluminophosphate molecular sieve SAPO-11 at normal pressure

A technology of SAPO-11 and silicoaluminophosphate, which is applied in the direction of molecular sieve characteristic silicoaluminophosphate, molecular sieve and alkali exchange phosphate, etc., can solve the problems of inconvenient synthesis and high price of ionic liquids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Weigh 20.0 grams of pentaerythritol and 40.0 grams of tetrabutylammonium bromide, grind and mix them, place them in a 150 mL beaker, heat them on a hot plate to melt them, and stir them until a transparent liquid is formed to obtain a eutectic mixture. Add 3.89 grams of phosphoric acid dropwise to the eutectic mixture, stir well, then add 7.1 grams (30.0%) of acidic silica sol, then add 0.50 grams of hydrofluoric acid (40.0%), and add 3.1 grams of di-n-propylamine to the eutectic In the mixture, stir evenly; slowly add 2.85 grams of Shandong aluminum powder from the aluminum source to the above mixed solution, continue to stir the resulting mixed sol for half an hour; transfer the above mixed sol to a 150 ml round bottom flask, use a heating mantle to heat, and stir magnetic , The condenser is connected to the flask with water cooling, at 180 o C crystallized for 12 hours. Then the reactant was cooled to room temperature, 50 ml of deionized water was added and stirred, a...

Embodiment 2~5

[0035] The specific steps and synthesis conditions are similar to Example 1, but the crystallization temperature is 160, 170, 180, 190 o C, the crystallization time is 24 hours.

Embodiment 6

[0037] The specific steps and synthesis conditions are similar to those in Example 1, but the eutectic mixture is made of 15 grams of pentaerythritol and 45 grams of tetrabutylammonium bromide. The crystallization reaction is carried out in a 150 ml static reactor, and the constant temperature is 180 in a rotating oven. o C crystallized for 12 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com