Water-soluble ceramic core and preparation method thereof

A ceramic core and water-soluble technology, which is applied in the field of ceramic cores, can solve the problem that resin sand cores have a large amount of gas generation and are not popular; it is reported that Hefei University of Technology and other units have successfully developed fused corundum soluble cores; Chengdu Dongfang Electric Co., Ltd. The factory has successfully developed a potassium carbonate silica sand soluble core; Meng Shuangfen and others have successfully developed a water soluble core for the production of steam turbine steel castings; there are also some problems in the development and application of this technology abroad, such as corrosion of castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

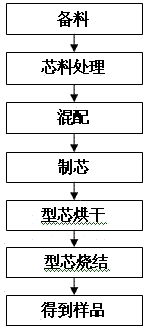

Method used

Image

Examples

Embodiment Construction

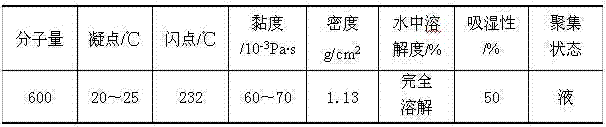

[0012] raw material

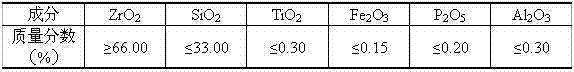

[0013] 1.1 Core matrix material

[0014] The present invention adopts fused corundum powder and zircon sand powder, and its chemical composition should meet the requirements of Table 1 and Table 2 respectively, that is, α-Al in fused corundum 2 o 3 The content is not less than 98.5%, ZrO in zircon sand 2 The content is not less than 66.0%.

[0015] Table 1 Chemical composition of fused corundum powder

[0016]

[0017] Table 2 Chemical composition of zircon sand powder

[0018]

[0019] Fused corundum has high melting point (2030°C) and high density (3.99~4.00g / cm 3 ), dense structure, good thermal conductivity, small thermal expansion coefficient (86×10 -7 1 / ℃) and uniform, it belongs to the amphoteric oxide, it is weakly alkaline or neutral at high temperature, and has good chemical stability; it has strong acid and alkali resistance, and can be used in the action of oxidizing agents, reducing agents or various metal liquids The follow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com