Liquid crystal medium composition

A technology of liquid crystal medium and composition, which is applied in the field of liquid crystal display devices, can solve problems such as the decrease in contrast of liquid crystal panels, achieve the effects of improving contrast and optical effects, and avoiding poor alignment of liquid crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

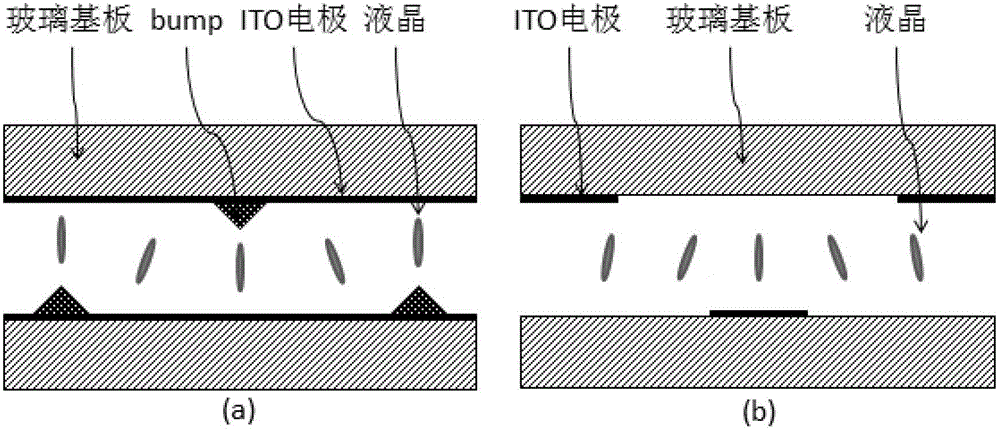

Problems solved by technology

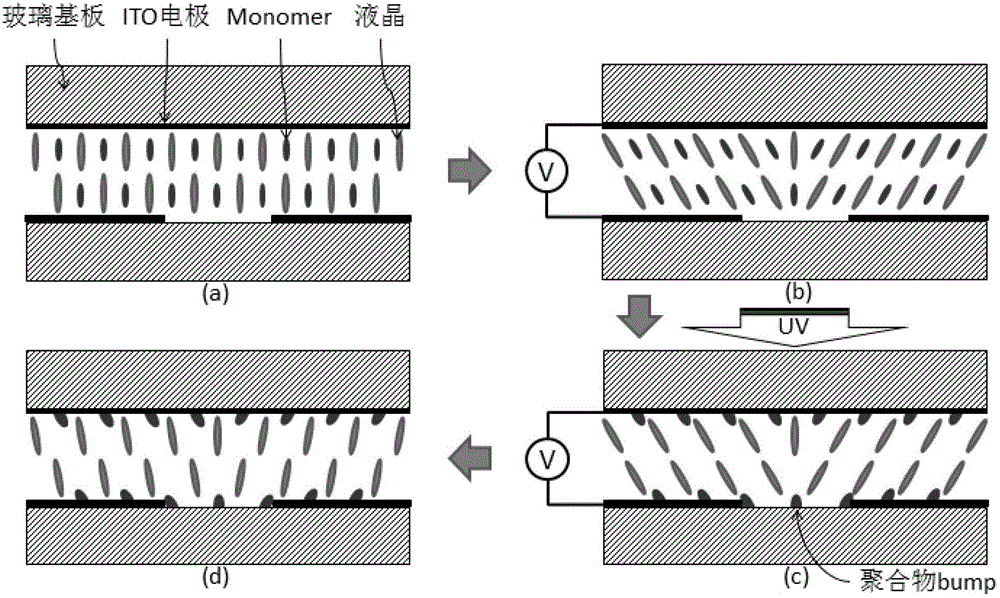

Method used

Image

Examples

Embodiment 1

[0039] The component contents involved in this embodiment are given according to the contents specified in Table 1 and Table 2.

[0040] Step 1. Add the single-polymerization-based monomer with the structure described in formula (3) and the double-polymerized-based monomer with the structure described in formula (4) to T ni 75°C, △n is 0.095 (25°C, 589nm), △ε is -2.8 (25°C, 1kHz) in the mixture of negative liquid crystal material and stabilizer, so as to form a uniform liquid crystal medium composition;

[0041]

[0042] Among them, the molecular weight of the single polymeric monomer corresponding to the formula (3) is 316, and the molecular weight of the double polymeric monomer corresponding to the formula (4) is 364.

[0043] Step 2: Drop the liquid crystal medium composition formed in step 1 on the prepared thin film transistor array substrate by ODF method, then combine the thin film transistor array substrate with the CF substrate, and then solidify the frame glue to...

Embodiment 2

[0046] The component contents involved in this embodiment are given according to the contents specified in Table 1 and Table 2.

[0047] Step 1. Add the single-polymerization-based monomer with the structure described in formula (5) and the double-polymerized-based monomer with the structure described in formula (6) to T ni 75°C, △n is 0.095 (25°C, 589nm), △ε is -2.8 (25°C, 1kHz) in the mixture of negative liquid crystal material and stabilizer, so as to form a uniform liquid crystal medium composition;

[0048]

[0049] Among them, the molecular weight of the monopolymeric monomer corresponding to the formula (5) is 250, and the molecular weight of the tripolymeric monomer corresponding to the formula (6) is 424.

[0050] Step 2: Drop the liquid crystal medium composition formed in step 1 on the prepared thin film transistor array substrate by ODF method, then combine the thin film transistor array substrate with the CF substrate, and then solidify the frame glue to form a...

Embodiment 3

[0053] The component contents involved in this embodiment are given according to the contents specified in Table 1 and Table 2.

[0054] Step 1. Add the single-polymerization-based monomer with the structure described in formula (7), the double-polymerized-based monomer with the structure described in formula (8), and the tri-polymerized-based monomer with the structure described in formula (9) into T ni 75°C, △n is 0.095 (25°C, 589nm), △ε is -2.8 (25°C, 1kHz) in the mixture of negative liquid crystal material and stabilizer, so as to form a uniform liquid crystal medium composition;

[0055]

[0056]

[0057] Among them, the molecular weight of the single polymeric monomer corresponding to the formula (7) is 254, the molecular weight of the double polymeric monomer corresponding to the formula (8) is 282, and the molecular weight of the tripolymeric monomer corresponding to the formula (9) is 372.

[0058] Step 2: Drop the liquid crystal medium composition formed in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com