LED (light emitting diode) high-efficient conversion hollow glass curtain wall and manufacturing method

A technology of glass curtain wall and manufacturing method, which is applied to the installation of window glass, chemical instruments and methods, glass/slag layered products, etc. It can solve the problems of butt connection of LED luminescent transparent curtain wall, thermal expansion coefficient of surface glass, It does not solve the heat dissipation problems of LED chips, and achieves the effects of reducing energy consumption, improving light conversion efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

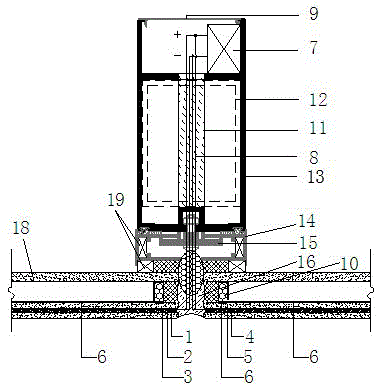

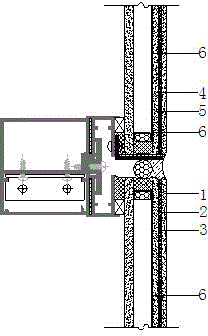

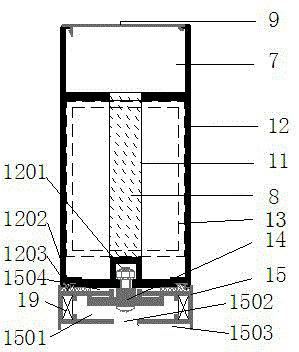

[0014] Embodiment 1: with reference to attached Figure 1-3. A hollow glass curtain wall with efficient conversion of LED performance, including an LED display glass screen. The hollow glass curtain wall with high efficiency conversion of LED performance is composed of glass or tempered glass layer 1 and LED dot matrix glass mold tape layer 5 superimposed (bonded) to form LED hollow glass Display layer, one side of LED dot matrix glass mold belt layer (heat-absorbing glass) 5 is embedded with a layer of conductive metal lattice network 3 composed of LED positive and negative electrodes or one side of LED dot matrix glass mold belt layer 5 is provided with conductive film The conductive metal lattice network (3) is formed, the LED chip 4 is located at the intersection of the conductive metal lattice network, and the back glass or back tempered glass 18 is bonded to the LED lattice glass mold belt layer 5 through the hollow aluminum strip 17 The backside and the back layer glas...

Embodiment 2

[0015] Embodiment 2: On the basis of Embodiment 1, the first surface of the quartz glass layer is a frosted glass surface, in order to minimize reflection.

Embodiment 3

[0016] Embodiment 3: On the basis of Embodiment 1, a method for manufacturing a hollow glass curtain wall with efficient conversion of LED performance, ⑴ According to the size of the LED lattice glass mold tape layer, the conductive metal lattice network 3 with positive and negative poles is made, and then the heat-absorbing glass is heated to the melting and softening point, and the conductive metal lattice network 3 with positive and negative poles is formed. Press into the melted and softened heat-absorbing glass surface; ⑵ A heat-absorbing and heat-dissipating layer 6 is placed on the back of the heat-absorbing glass; ⑶ Paste the LED chip 4 on the intersection of the conductive metal lattice network 4 and form the LED lattice glass tape layer 5, then cover the PVB or EVA film 2 on the LED lattice glass tape layer 5, and then cover the quartz glass layer 1 Superimposed on PVB or EVA film and glued together with heat-absorbing glass, the LED lamp can efficiently convert i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com