Method for measuring drift amount of buried graph after epitaxial growth

A technology of pattern drift and epitaxial growth, applied in measurement devices, instruments, optical devices, etc., can solve problems such as measurement accuracy of only 0.1 μm, inability to measure measurement, and complicated operation, and achieves reduction of human bias, simple method, and measurement. simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with accompanying drawings and examples.

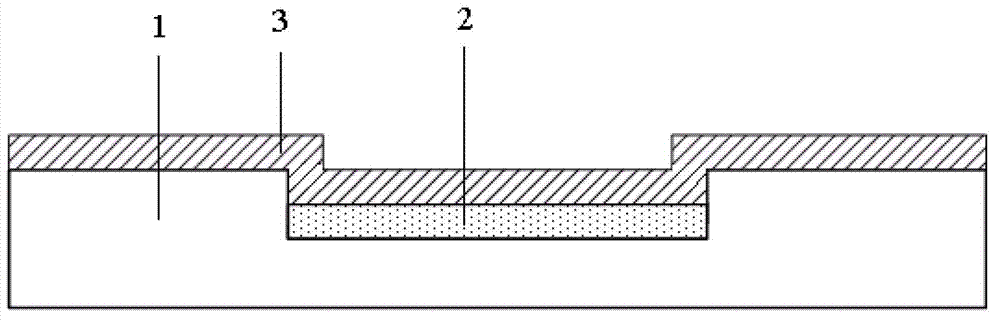

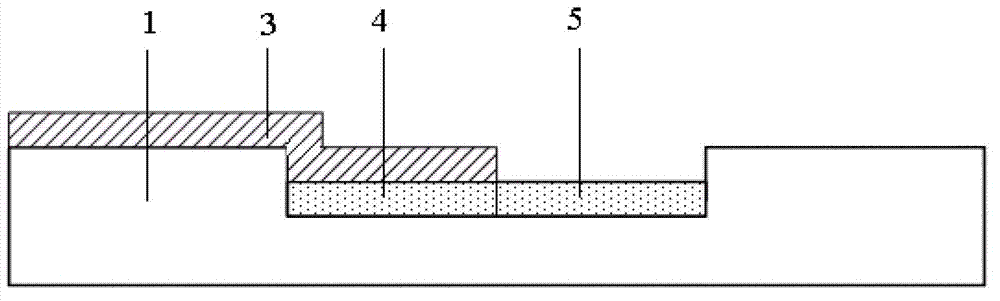

[0032] The method for measuring the drift of buried layer pattern after epitaxial growth of the present invention is to utilize the feature that selective epitaxial growth technology can carry out epitaxial growth in a specific area of silicon substrate material, and other areas do not carry out epitaxial growth, to realize the same buried layer pattern. Epitaxial growth does not occur in protected areas and epitaxial growth occurs in unprotected areas. By measuring the relative position data of the protected area and the unprotected area, the drift data of the buried layer pattern after epitaxy is obtained. Concrete method of the present invention is as follows:

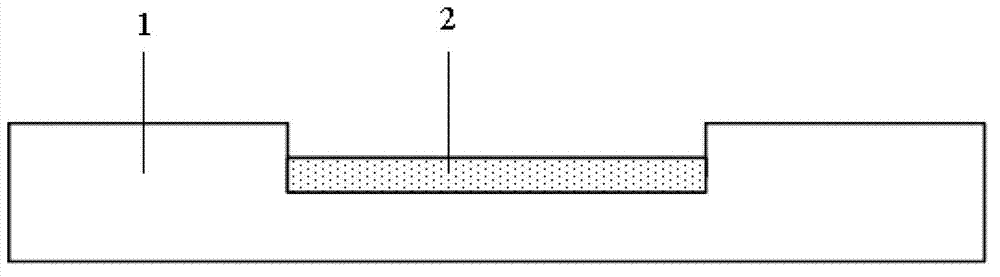

[0033] 1. Using photolithography plate A, form buried pattern 2 on silicon wafer 1:

[0034] (1) Silicon wafer 1 is: P type, crystal orientation, resistivity 7~13Ω·cm, and 1# liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com