Closed type ultrasonic wave water and heat meter

An ultrasonic and thermal energy meter technology, applied in calorimeters, measuring heat, measuring devices, etc., can solve the problems of not improving the flow rate, losing normal transmission and reception, rough surface, etc., to achieve increased propagation time difference, measurement accuracy and The effect of increased sensitivity and increased water flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

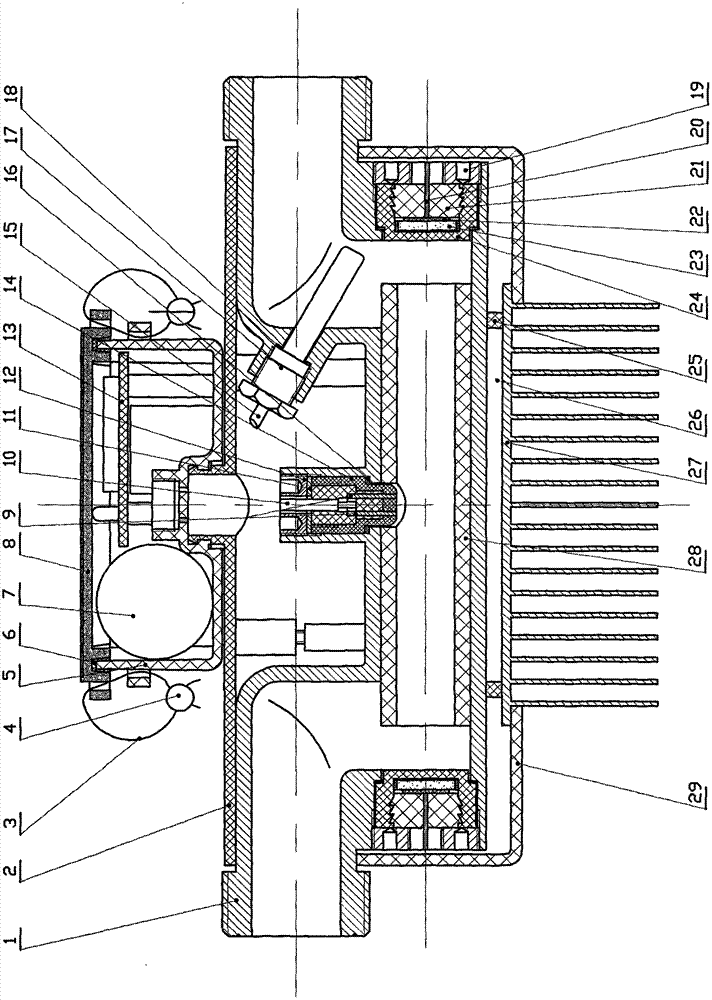

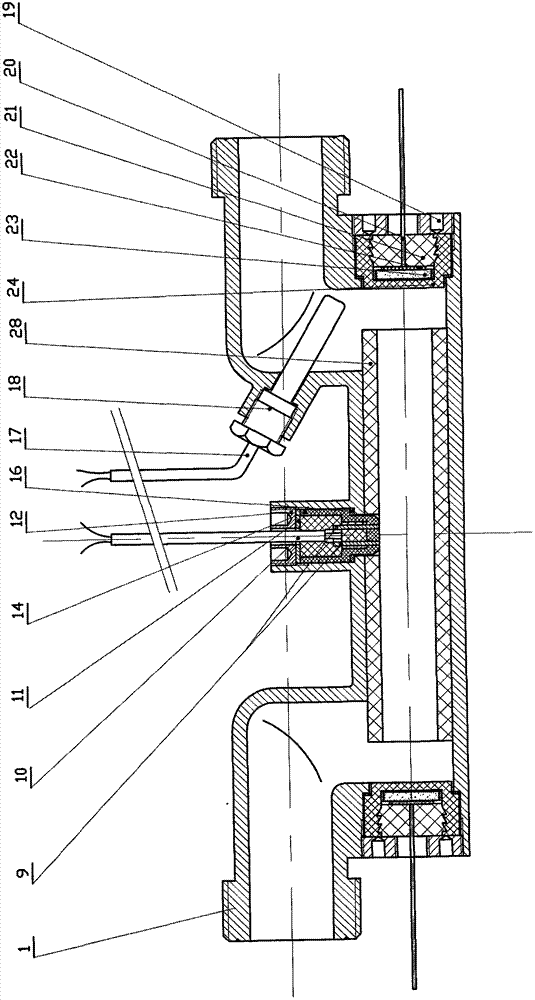

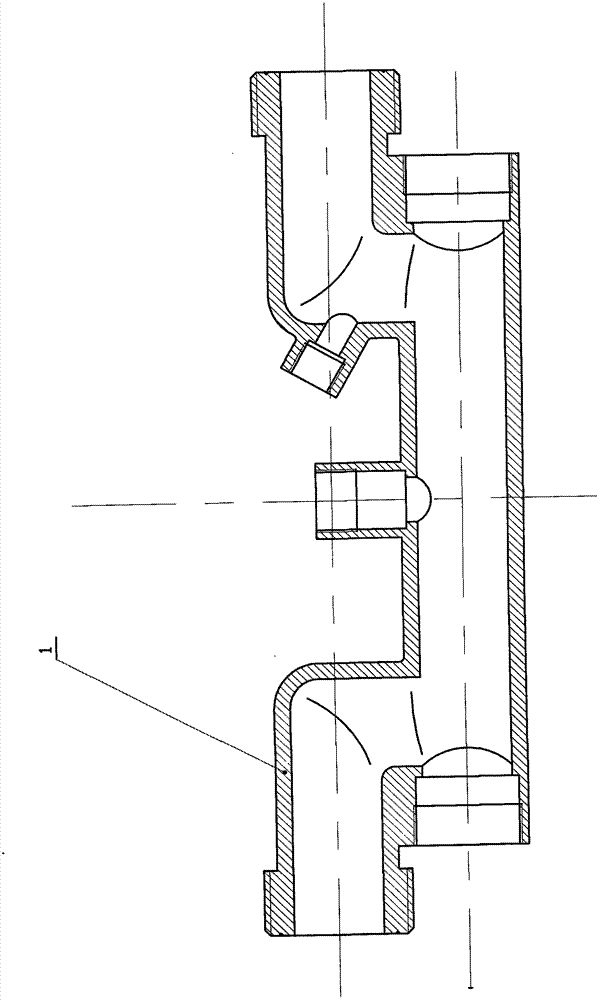

[0032] The present invention is realized like this: it is to make watch case (1) into U-tube-like shape, and the top horizontal direction of its U-shaped tube is provided with inlet and outlet pipes; There is a through horizontal tube, and internal threads are made at both ends, a side tube is made on the wall of the horizontal tube, and an internal thread is made at the end of the side tube, and the outer wall of the vertical tube side of the U-shaped tube There is a side through pipe, and an internal thread is also made at the tail end of the side through pipe. Insert speed measuring tube (28) in the through horizontal tube of U-shaped pipe, the internal diameter of speed measuring tube (28) will be smaller than the aperture of inlet and outlet, and the side wall of speed measuring tube (28) also has side hole, and this The side hole is aligned with the inner hole of the side tube on the cross tube. The two ends of the horizontal pipe of the U-shaped pipe are packed with an u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com