Biomedical calcium phosphate/zinc oxide nano-rod array composite coating on surface of medical metal and preparation method thereof

A zinc oxide nanorod and metal surface technology, which is applied in the fields of metal material coating technology, coating, medical science, etc., can solve the difficulty of coating, the difficulty of adjusting the hydrophobic and hydrophilic properties of the surface, and the hydrophilicity of calcium phosphate coating Poor characteristics and other problems, to achieve the effect of promoting osteogenesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

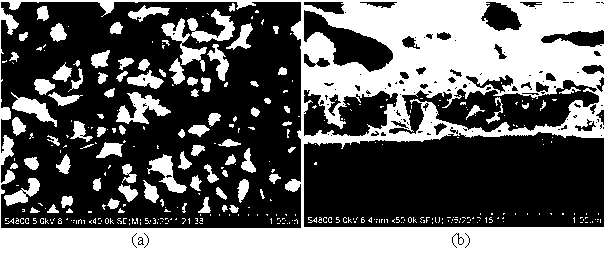

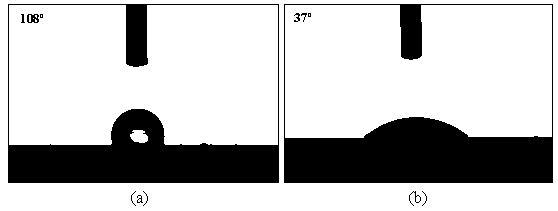

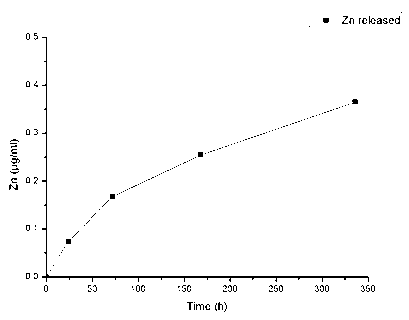

[0028] 1) Preparation of ZnO nanorod arrays grown on the metal surface:

[0029] a. Dissolve zinc acetate and ethanolamine in ethanol at a molar ratio of 1:1 to prepare an ethanol solution of zinc acetate and ethanolamine with a concentration of 0.1M. Take 10 μL of the ethanol solution of zinc acetate and ethanolamine and spin-coat it on medical metal at 5000rpm Surface, heat treatment at 400°C for 0.5h after spin coating to form a medical metal surface with a zinc oxide seed layer for use;

[0030] b. Dissolve zinc nitrate and hexamethylenetetramine in water at a molar ratio of 1:1, and prepare a growth mother solution for the hydrothermal reaction of zinc nitrate and hexamethylenetetramine with a concentration of 0.02M, which will have zinc oxide crystals The medical metal surface of the seed layer and the growth mother liquid were put into the reaction kettle, and after being kept at 80°C for 2 hours, the medical metal surface was cleaned with deionized water and dried to o...

Embodiment 2

[0036] 1) Preparation of ZnO nanorod arrays grown on the metal surface:

[0037]a. Dissolve zinc acetate and ethanolamine in ethanol at a molar ratio of 1:1, prepare an ethanol solution of zinc acetate and ethanolamine with a concentration of 0.75M, take 10 μL of the precursor solution and spin-coat it on the surface of the metal substrate at 5000 rpm, spin-coat After the end, heat treatment at 400°C for 0.5h to form a zinc oxide seed layer;

[0038] b. Dissolve zinc nitrate and hexamethylenetetramine in water at a molar ratio of 1:1, configure the growth mother solution of the hydrothermal reaction of zinc nitrate and hexamethylenetetramine with a concentration of 0.02M, and prepare in a The sample and the growth mother solution were put into the reaction kettle, kept at 80°C for 6 hours, the substrate was taken out and the surface of the sample was cleaned with deionized water and dried to obtain the ZnO nanorod array grown on the metal surface;

[0039] 2) Preparation of b...

Embodiment 3

[0043] 1) Preparation of ZnO nanorod arrays grown on the metal surface:

[0044] a. Dissolve zinc acetate and ethanolamine in ethanol at a molar ratio of 1:1, prepare an ethanol solution of zinc acetate and ethanolamine with a concentration of 0.05M, take 20 μL of the precursor solution and spin-coat it on the surface of the metal substrate at 7000 rpm, spin-coat After the end, heat treatment at 400°C for 1 hour to form a zinc oxide seed layer;

[0045] b. Dissolve zinc nitrate and hexamethylenetetramine in water at a molar ratio of 1:1, configure a growth mother solution for the hydrothermal reaction of zinc nitrate and hexamethylenetetramine with a concentration of 0.05M, and prepare in a. The sample and the growth mother solution were put into the reaction kettle, kept at 100°C for 2 hours, the substrate was taken out, the surface of the sample was cleaned with deionized water and dried, and the array of zinc oxide nanorods grown on the metal surface was obtained;

[0046]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com