Method and device for spraying reducing agent used for selective catalytic reduction (SCR) of NOx

An injection method and technology of reducing agent, applied in the field of boiler SCR denitration, can solve the problems of difficult urea technology, energy consumption, investment and operation cost, etc., to reduce denitration operation cost and investment cost, reduce urea consumption, The effect of saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following non-limiting examples illustrate the invention.

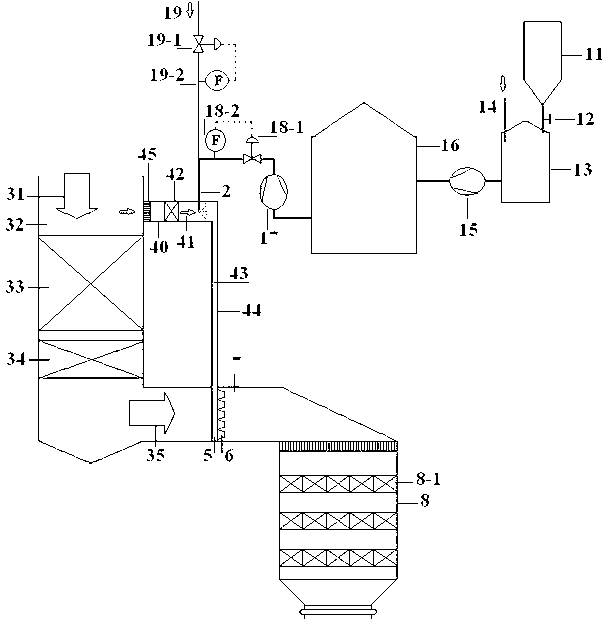

[0030] Such as figure 1 As shown, by opening the valve 12, the urea in the urea granule silo 11 falls into the urea dissolving tank 13. In the urea dissolving tank 13, urea is mixed with the added water 14 and dissolved. The urea solution generated after the urea particles dissolve is sent to the urea solution storage tank 16 through the urea solution circulation pump 15 for storage. This embodiment only lists one of the urea solution preparation schemes, and this patent does not limit how to prepare the urea solution, only the urea solution is needed.

[0031] The urea solution in the urea solution storage tank 16 is sent into the urea solution spray gun 2 installed in the urea decomposition pipeline 40 through the urea solution feeding pump 17 . The compressed air 19 enters the urea solution spray gun 2 to atomize the urea solution and inject it into the urea decomposition flue gas 41 . Adjust the ur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com