Hydrodeoxygenation catalyst for Fischer Tropsch synthesis oil and preparation method and application of hydrodeoxygenation catalyst

A deoxidation catalyst and Fischer-Tropsch synthesis technology, applied in organic compound/hydride/coordination complex catalysts, metal/metal oxide/metal hydroxide catalysts, molecular sieve catalysts, etc., can solve the problem of increasing equipment investment and operating costs , single carrier and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

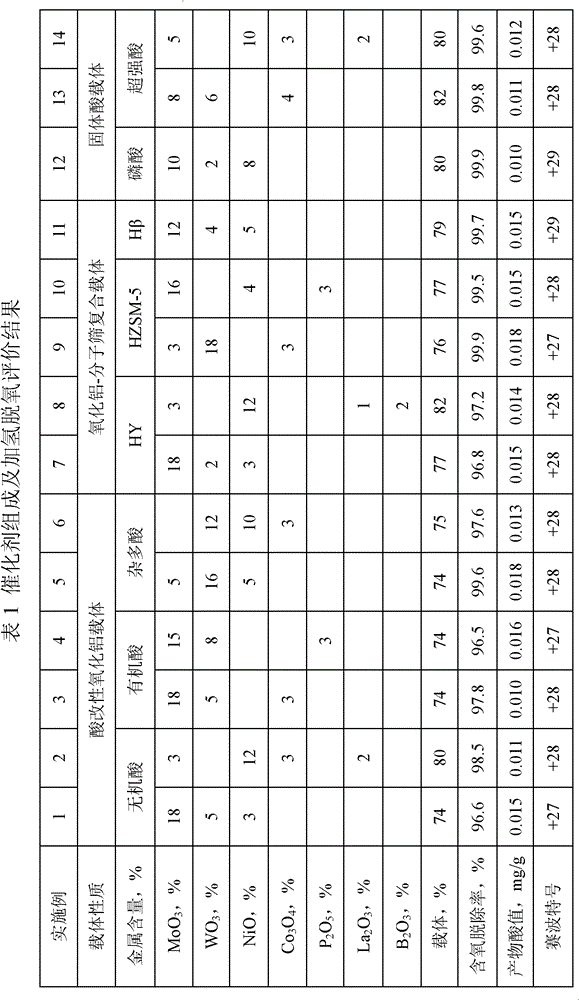

Examples

Embodiment 1

[0049] Weigh 100.0g of pseudo-boehmite (dry basis weight) and 3.0g of scallop powder and mix evenly, add 60ml of 4% dilute nitric acid, mix and shape in an extruder, dry at 110°C, and roast at 550°C After 8 hours, the alumina carrier was prepared; then the alumina carrier was impregnated with 1mol / L phosphoric acid solution, dried at 120°C, and calcined at 500°C for 8 hours to obtain the phosphoric acid-modified alumina carrier. Weigh 74.0g of modified alumina carrier, ammonium metatungstate ((NH 4 ) 2 W 4 o 13 ·8H 2 O, 6.06g) and ammonium heptamolybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 (22.05g) is formulated into a mixed aqueous solution of a certain concentration, the carrier is added to the above solution, immersed for 12 hours, dried at 110°C for 12 hours, and roasted at 450°C for 4 hours; according to the equal volume impregnation method, the above semi-finished catalyst Added to nickel nitrate (Ni(NO 3 ) 2 ·6H 2 (2, 11.67 g) was immersed in an aqueous solution for 1...

Embodiment 2

[0052] Weigh 100.0g of pseudo-boehmite (dry basis weight) and 3.0g of scallop powder and mix evenly, add 60ml of 4% dilute nitric acid, mix and shape in an extruder, dry at 110°C, and roast at 550°C After 8 hours, the alumina carrier was prepared; then the alumina carrier was impregnated with 1mol / L phosphoric acid solution, dried at 120°C, and calcined at 500°C for 8 hours to obtain the phosphoric acid-modified alumina carrier. Weigh 80.0 g of modified alumina carrier, nickel nitrate (Ni(NO 3 ) 2 ·6H 2 O, 46.68g) and ammonium heptamolybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 (2, 3.68g) is formulated into a mixed aqueous solution with a certain concentration, the carrier is added to the above solution, immersed for 12 hours, dried at 110°C for 12 hours, and roasted at 450°C for 4 hours; according to the equal volume impregnation method, the above catalyst semi-finished product Added to cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O, 10.88g) and lanthanum nitrate (La(NO 3 ) 3 .6H 2 (2...

Embodiment 3

[0055] Weigh 100.0g of pseudo-boehmite (dry basis weight) and 3.0g of scallop powder and mix evenly, add 60ml of 4% dilute nitric acid, mix and shape in an extruder, dry at 110°C, and roast at 550°C After 8 hours, the alumina carrier was prepared; then the alumina carrier was impregnated with 1mol / L oxalic acid solution, dried at 120°C, and calcined at 500°C for 8 hours to obtain the oxalic acid-modified alumina carrier. Weigh 74.0g of modified alumina carrier, ammonium metatungstate ((NH 4 ) 2 W4 o 13 ·8H 2 O, 6.06g) and ammonium heptamolybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 (22.05g) is formulated into a mixed aqueous solution of a certain concentration, the carrier is added to the above solution, immersed for 12 hours, dried at 110°C for 12 hours, and roasted at 450°C for 4 hours; according to the equal volume impregnation method, the above semi-finished catalyst Added to cobalt nitrate (Co(NO 3 ) 2 ·6H 2 (2, 10.88g) was immersed in an aqueous solution for 12 hours, dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com