Chlorine-free high efficiency cement grinding aid and preparation method

A cement grinding aid and the technology of the grinding aid, which are applied in the field of cement production and processing, can solve the problems of unfavorable cement performance, high production cost, narrow adaptability, etc., achieve good grinding aid effect, stable application performance, and solve the problem of large fluctuation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The ingredients of the grinding aid are 10% of molasses, 5% of wood calcium, 8% of sodium sodium hydroxymethylglycinate, 15% of AMPS copolymer, 5% of water glass, 8% of wheatgrass lignin and the balance of water.

[0020] This example is applied to 32.5P·S·A slag portland cement, the proportion of cement is: clinker 55%, granulated blast furnace slag 35%, gypsum 10%. According to the ratio of 0.08% of the cement mass, the grinding aid of the present invention is added, and the grinding time of the blank sample and the test sample is both 29 minutes.

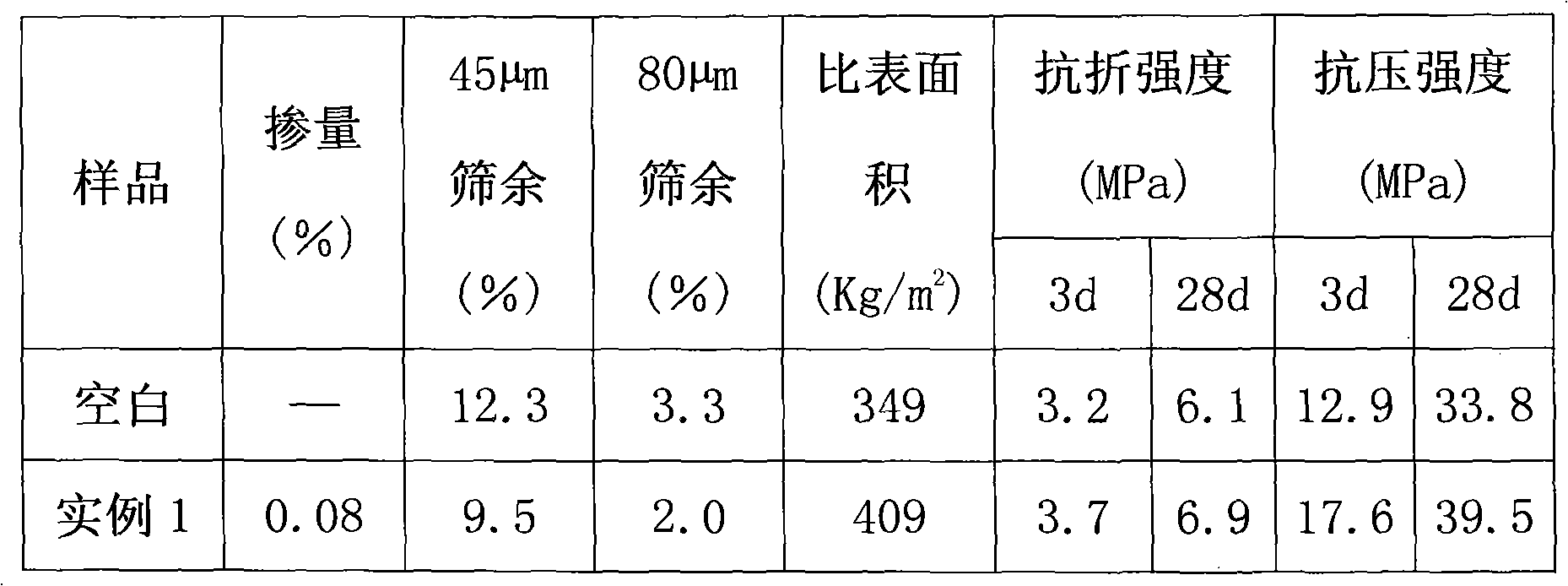

[0021] The specific experimental results are shown in the table below:

[0022]

[0023] Experimental data show that the product of the present invention has a good grinding aid effect on 32.5P·S·A slag portland cement. Compared with the blank cement, the cement mixed with 0.08% of the grinding aid of the invention has a 22.8% reduction in sieve residue at 45 μm, a 39.4% reduction in sieve residue at 80 μm, a 17.2% inc...

Embodiment 2

[0025] The ingredients of the grinding aid are 15% molasses, 8% wood calcium, 5% sodium hydroxymethylglycinate, 10% AMPS copolymer, 5% water glass, 1% silicone oil, 5% wheatgrass lignin and Balance water.

[0026] Apply this example to 42.5P·O ordinary Portland cement. The cement proportion is: 80% clinker, 5% granulated blast furnace slag, 5% fly ash, 5% gypsum, and 5% limestone. The grinding aid of the present invention is added in a proportion of 0.1% of the cement mass, and the grinding time of the blank sample and the test sample is both 30 minutes.

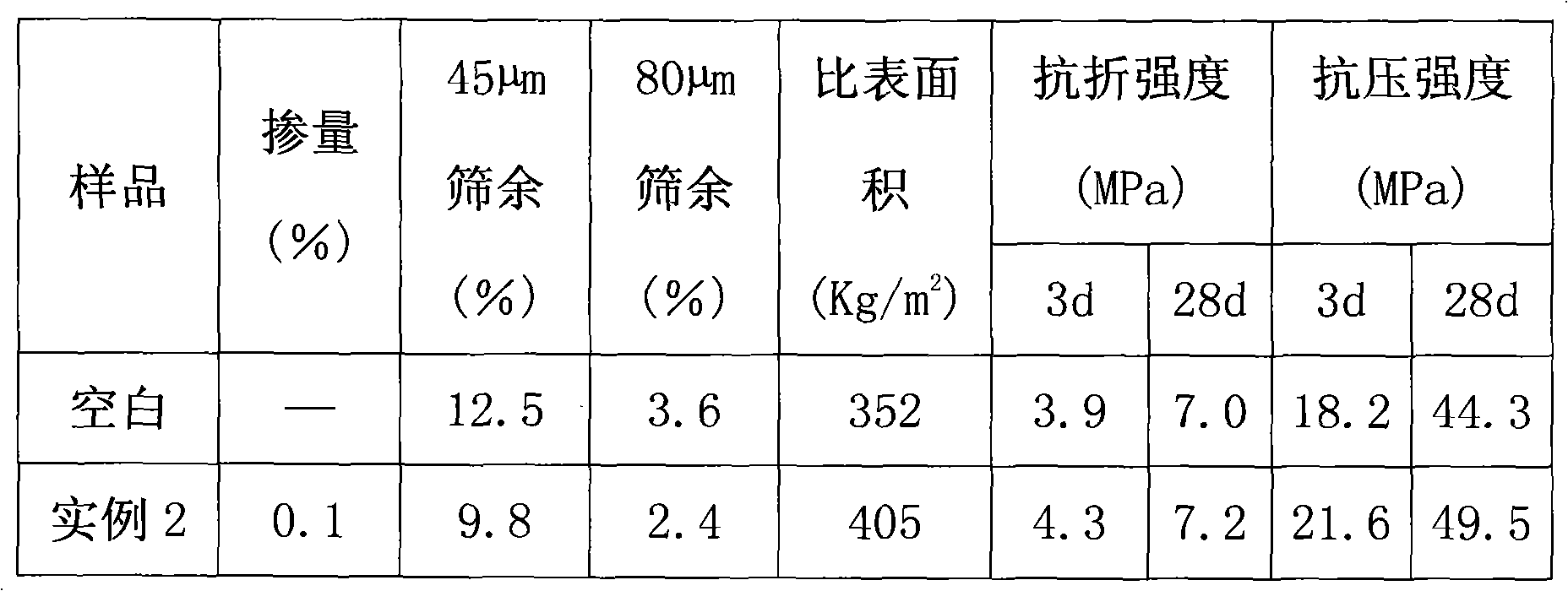

[0027] The specific experimental results are shown in the table below:

[0028]

[0029] Experimental data show that the product of the present invention has a good grinding aid effect on 42.5P·O ordinary Portland cement. Compared with the blank cement, the cement mixed with 0.1% of the grinding aid of the invention has a 21.6% reduction in sieve residue at 45 μm, a 27.8% reduction in sieve residue at 80 μm, a 15.1% inc...

Embodiment 3

[0031] The ingredients of the grinding aid are 20% molasses, 5% wood calcium, 5% sodium hydroxymethylglycinate, 7% AMPS copolymer, 8% water glass, 1.2% silicone oil, 3% wheatgrass lignin and Balance water.

[0032] This example is applied to 32.5P·S·B slag portland cement, the proportion of cement is: clinker 35%, granulated blast furnace slag 55%, gypsum 10%. The grinding aid of the present invention is added in a proportion of 0.08% of the cement mass, and the grinding time of the blank sample and the test sample is both 29 minutes.

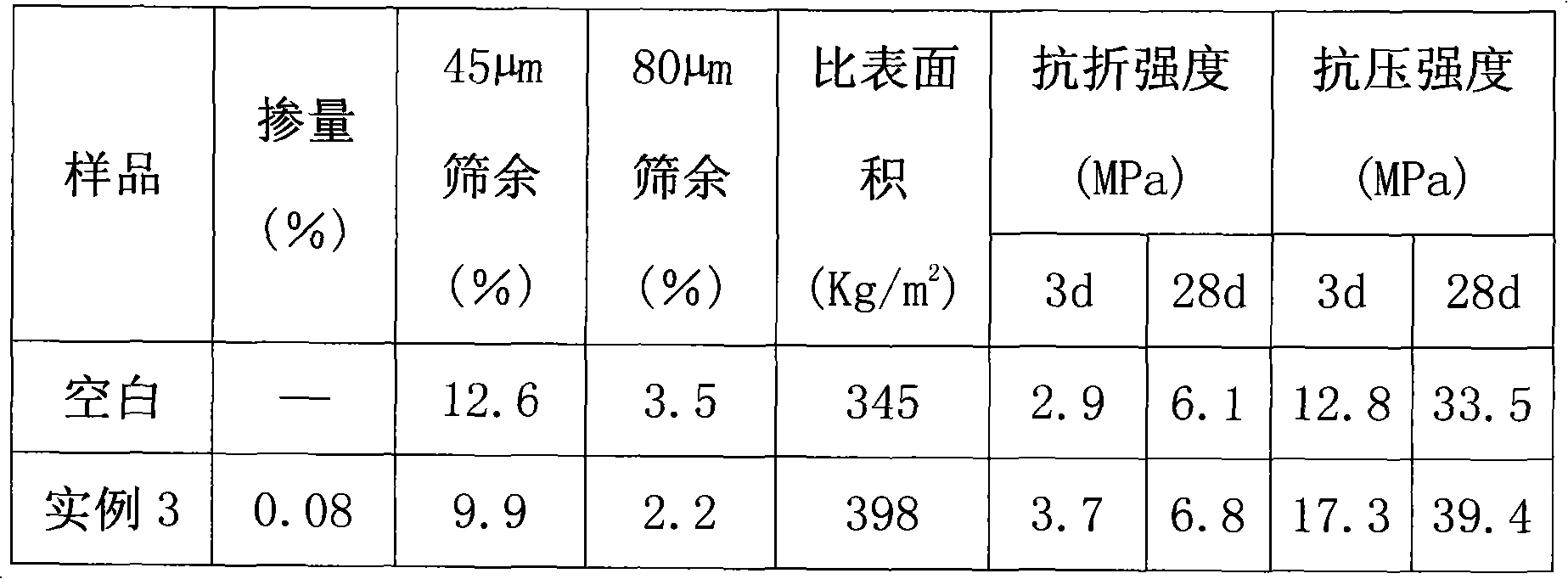

[0033] The specific experimental results are shown in the table below:

[0034]

[0035] Experimental data show that the product of the present invention has a good grinding aid effect on 32.5P·S·B slag portland cement. Compared with the blank cement, the cement mixed with 0.08% of the grinding aid of the invention has a 21.4% reduction in sieve residue at 45 μm, a reduction of 37.1% at 80 μm sieve residue, a 15.1% increase in specific sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com