Method for preparing superfine iron oxide red pigment by utilizing discarded selenium drum powdered ink

A technology of iron oxide red and toner, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve problems such as trachea and lung damage, great harm to human body, and harm to human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A. Put the collected waste toner cartridges in the waste toner cartridge crushing and magnetic separation device, and after crushing, magnetic separation, wind separation and other procedures, metal (iron, aluminum), plastic, and finally black organic toner are collected in sequence. ;

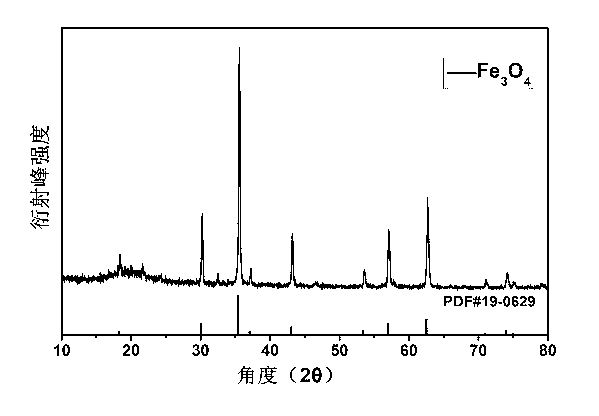

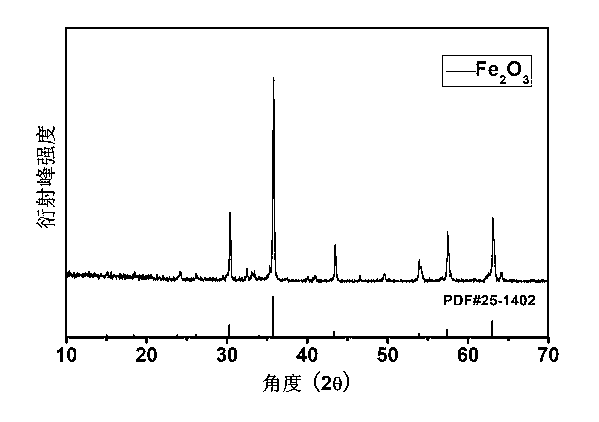

[0017] B. Place the obtained toner in a crucible, and calcinate in a muffle furnace at 500°C for three hours, and then dark red iron oxide powder can be obtained after natural cooling;

[0018] C. Add 50 ml of water to a 100 ml beaker, add 0.75 g of soda, which is 1.5% of the water mass, into the beaker, and stir evenly to obtain a clear solution;

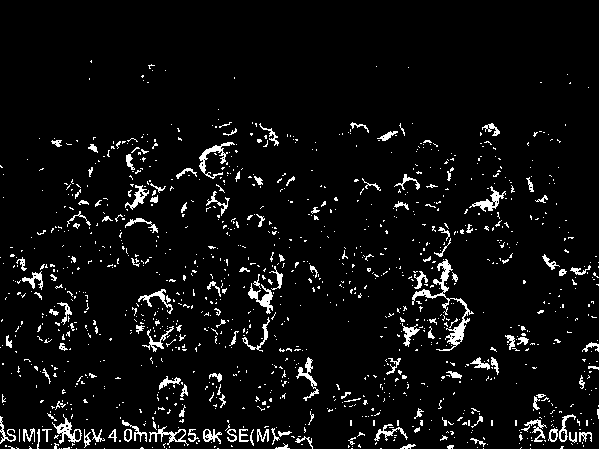

[0019] D. Weigh 50 g of the above-mentioned dark red powder into the above-mentioned clear solution, stir rapidly with the mixer, and then add 1% of the total mass, that is, 1.0 g of PVP (dissolved in a solution with a volume ratio of methanol to water of 1:1) and continue stirring. A red pigment slurry with good uniform dispersion can be o...

Embodiment 2

[0021] A. Put the collected waste toner cartridges in the waste toner cartridge crushing and magnetic separation device, and after crushing, magnetic separation, wind separation and other procedures, metal (iron, aluminum), plastic, and finally black organic toner are collected in sequence. ;

[0022] B. Place the obtained toner in a crucible, and calcinate in a muffle furnace at 500°C for three hours, and then dark red iron oxide powder can be obtained after natural cooling;

[0023] C. 30 L of water is added in the 50 L beaker, the soda that is 0.45 Kg of 1.5% of the water quality is added in the beaker, stir to obtain a clear solution;

[0024] D. Weigh 40 kg of the above-mentioned dark red powder and add it to the above-mentioned clear solution, stir rapidly with the mixer, and then add 1% of the total mass, that is, 0.704 Kg of PVP (dissolved in a solution with a volume ratio of methanol to water of 1:1) and continue stirring. The red pigment slurry with uniformity and g...

Embodiment 3

[0026] A. Put the collected waste toner cartridges in the waste toner cartridge crushing and magnetic separation device, and after crushing, magnetic separation, wind separation and other procedures, metal (iron, aluminum), plastic, and finally black organic toner are collected in sequence. ;

[0027] B. Place the obtained toner in a crucible, and calcinate in a muffle furnace at 500°C for three hours, and then dark red iron oxide powder can be obtained after natural cooling;

[0028] C. 30 L of water is added in the 50 L beaker, the soda that is 0.3 Kg of 1% of the water quality is added in the beaker, stir to obtain a clear solution;

[0029] D. Weigh 30 kg of the above-mentioned dark red powder and add it to the above-mentioned clear solution, stir rapidly with the mixer, and then add 0.8% of the total mass, that is, 0.48 Kg of PVP (dissolved in a solution with a volume ratio of methanol to water of 1:1) and continue stirring. The red pigment slurry with uniformity and goo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com