Process for capsicum oleoresin extraction by supercritical CO2

A technology of capsicum oleoresin and process method, which is applied in the fields of natural resin refining and bulk chemical production, etc. It can solve the problems of cumbersome process, solvent residue, process pipeline and solvent tank occupying a large space and transportation site, etc., and achieve simple process , low labor intensity, and the effect of well-preserved characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

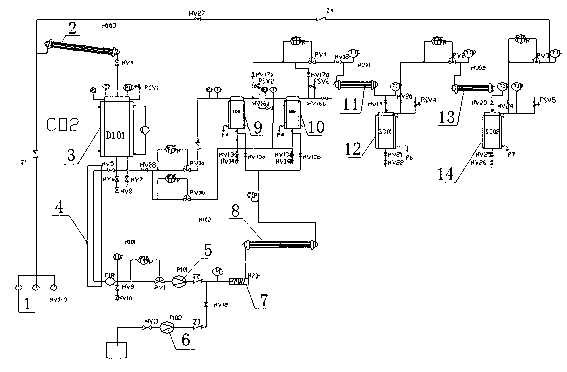

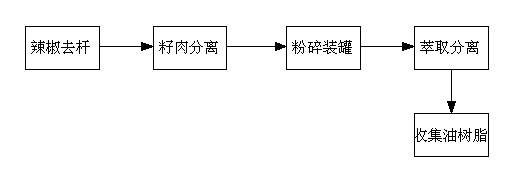

[0028] A kind of supercritical CO of the present invention 2 The technical process for extracting chili oleoresin, the technical process steps are: remove the stalk of dried chili, separate the seed meat, take 100kg of chili raw material and crush it into 30-40 mesh, put the crushed material into the material basket, and then put the material basket into Put it into the high-pressure extraction kettle, close the kettle cover and safety device, adjust and confirm the cycle pressure in the computer configuration to 40MPa, the temperature to 50℃, the flow parameter to 600kg / h, and feed CO 2 Into the extraction kettle, fill to the required extraction pressure above 40MPa, dissolve the solute, maintain the temperature of the system medium, and automatically start the regulating valve after reaching the system circulation pressure of 40MPa, and release the extract to the separation kettle through throttling expansion. The temperature in the process does not exceed 50°C before the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| disjoining pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com