Silicone rubber sealant and preparation method thereof

A manufacturing method and sealant technology, applied in chemical instruments and methods, adhesives, other chemical processes, etc., can solve problems such as difficult to meet immediate sealing performance, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further illustrate the technical means and effects that the present invention takes to achieve the intended purpose of the invention, below in conjunction with the preferred embodiments, the specific implementation, structure, characteristics and methods of the silicone rubber sealant and its manufacturing method proposed according to the present invention will be described below. Efficacy, detailed as follows.

[0017] The silicone rubber sealant provided by the invention is a paste with uniform appearance and no mechanical impurities, which can be used to fill the gap between the two parts of the automobile engine to play a role of sealing, wherein the two parts of the engine can be planar , can also be other shapes out of the plane, but the present invention does not limit the application field of the silicone rubber sealant.

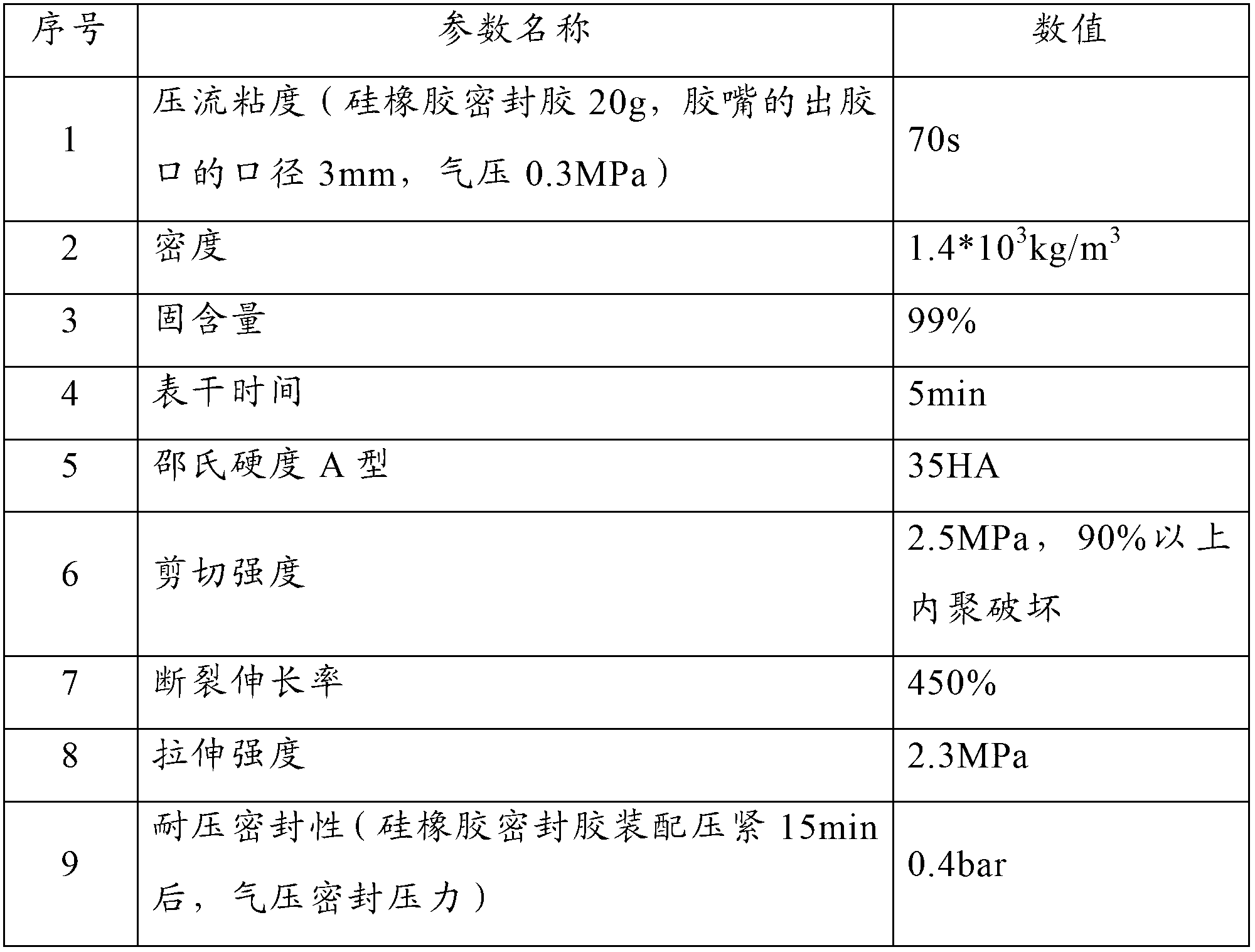

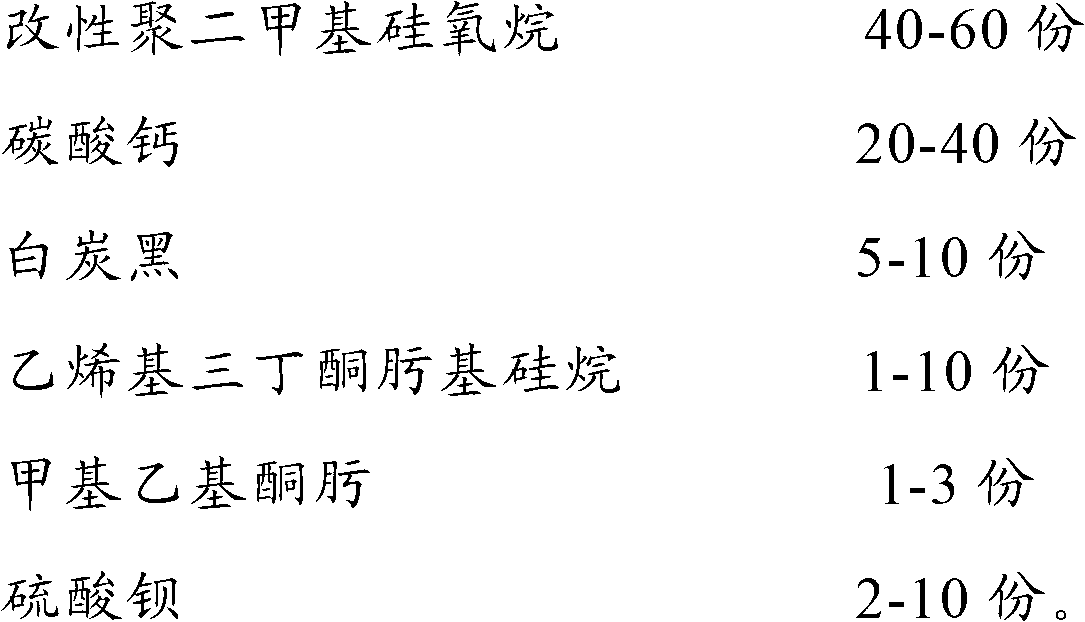

[0018] The silicone rubber sealant of the first embodiment of the present invention includes the following components and corresp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Oil absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com