Patents

Literature

39 results about "Methylethyl ketoxime" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multifunctional anti-radiation coating and preparation method thereof

The invention discloses a multifunctional anti-radiation coating and a preparation method thereof. The multifunctional anti-radiation coating consists of the following raw materials in parts by weight: 68.0-85.0 parts of a polyvinyl acetate emulsion, 2.0-3.0 parts of nano zinc oxide, 10.0-17.0 parts of titanium dioxide, 2.0-5.0 parts of copper powder, 18.0-30.0 parts of barium sulfate, 0.5-1.5 parts of CMC, 2.0-3.0 parts of manganese naphthenate, 0.5-1.5 parts of methyl ethyl ketoxime, 1.0-3.0 parts of dibutyl phthalate, 1.0-2.0 parts of polymethyl acrylate, 1.0-2.0 parts of benzotriazole, 6.0-8.0 parts of nano anion powder, 10.0-20.0 parts of deionized water, 1.0-3.0 parts of a suspending agent, 8.0-12.0 parts of a filler and 2.5-6.0 parts of a filming additive. The multifunctional anti-radiation coating disclosed by the invention is convenient to construct, rapid to cure, good in stability, environmental-friendly and non-toxic, is capable of not only effectively shielding radon gas, but also preventing electromagnetic radiation and ionization radiation, moreover is capable of effectively absorbing harmful gases such as formaldehyde, is capable of purifying air, and is a multifunctional anti-radiation coating.

Owner:湖南康宁达医疗科技股份有限公司

High-hypertonicity wear-resisting environment-friendly non-rust offset printing ink

The invention discloses high-hypertonicity wear-resisting environment-friendly non-rust offset printing ink. The high-hypertonicity wear-resisting environment-friendly non-rust offset printing ink is prepared from, by mass, 50-60 parts of connecting materials, 2-5 parts of plant pigments, 15-25 parts of alkyd resin, 3-5 parts of antiskinning agent, 1-3 parts of wax, 10-15 parts of plant oil derivatives, 0.1-0.5 part of stannic oxide powder, 1-3 parts of antifoaming agent and 1-3 parts of thickening agent. The antiskinning agent is one of or a mixture of more of cyclohexanone-oxime, ethyl methyl ketone oxime, butyraldoxime and dipentene, and is mixed with plant oil, and the ink is prepared. The novel and efficient antiskinning agent replaces traditional hydroquinone, phenol toxicity is avoided, and the ink has long-time non-skinning and non-rust performance.

Owner:苏州市博来特油墨有限公司

Waterproof adhesive compositions

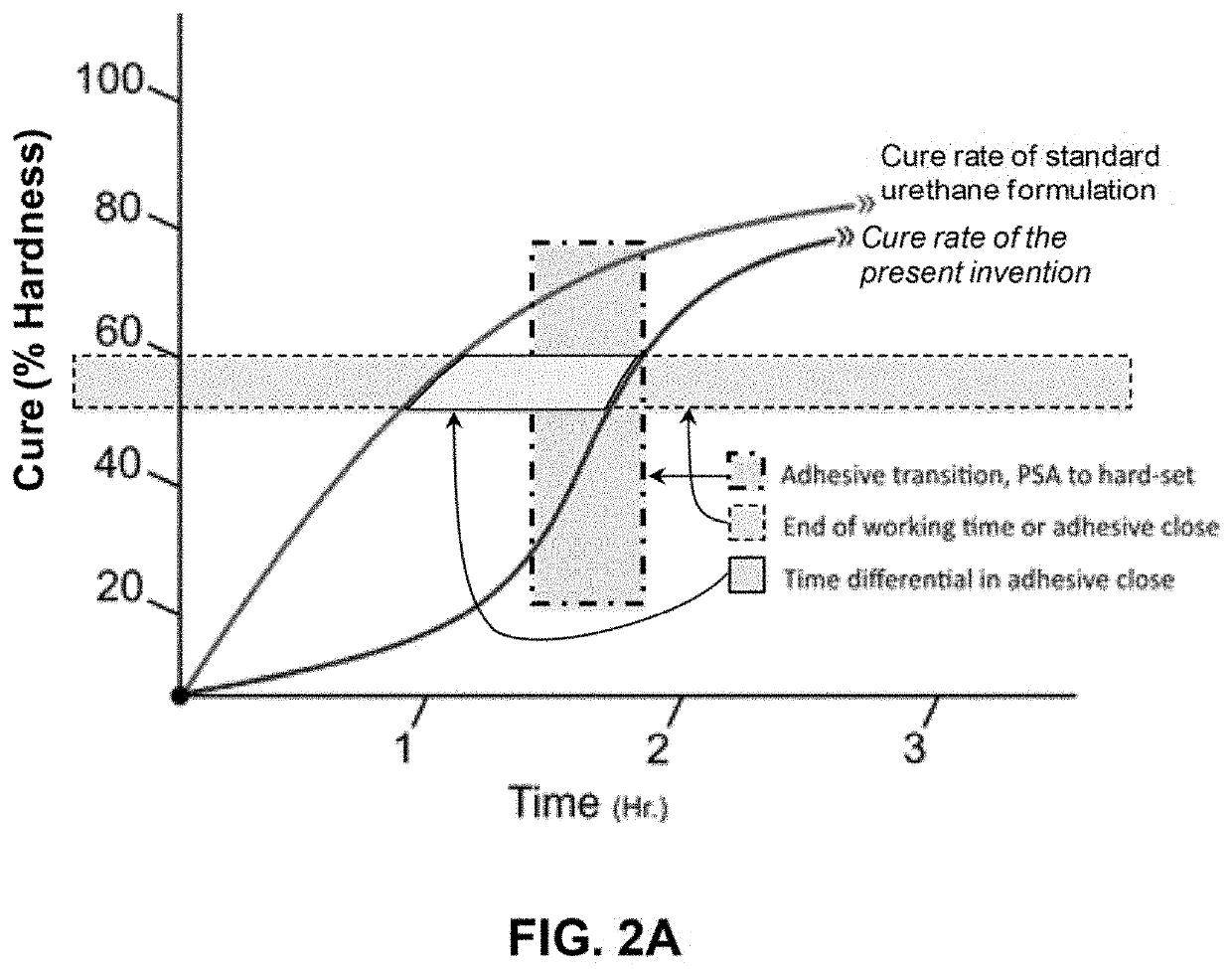

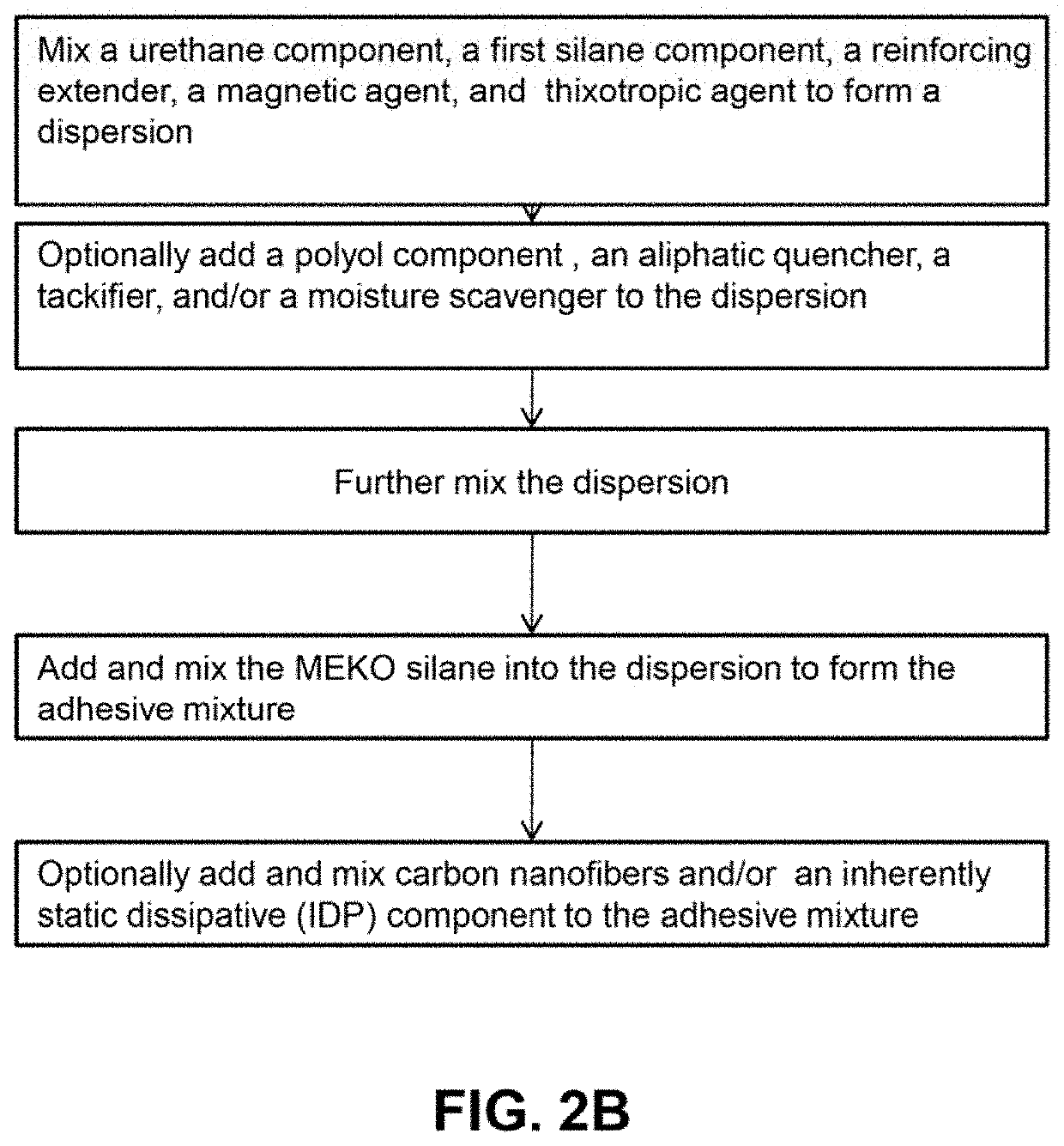

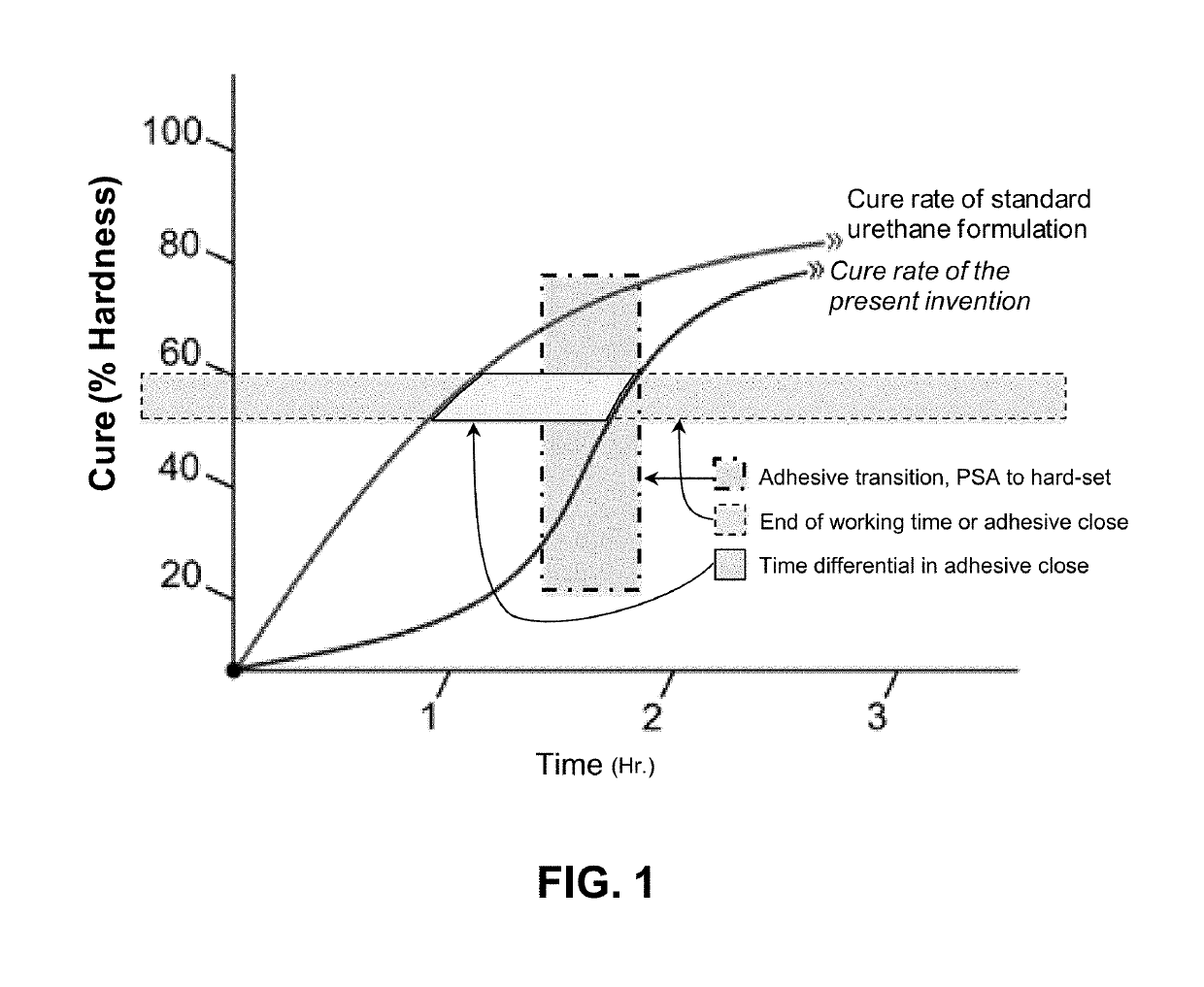

InactiveUS20180265759A1Efficient productionSuppresses cure rateNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEndcappingPolymer science

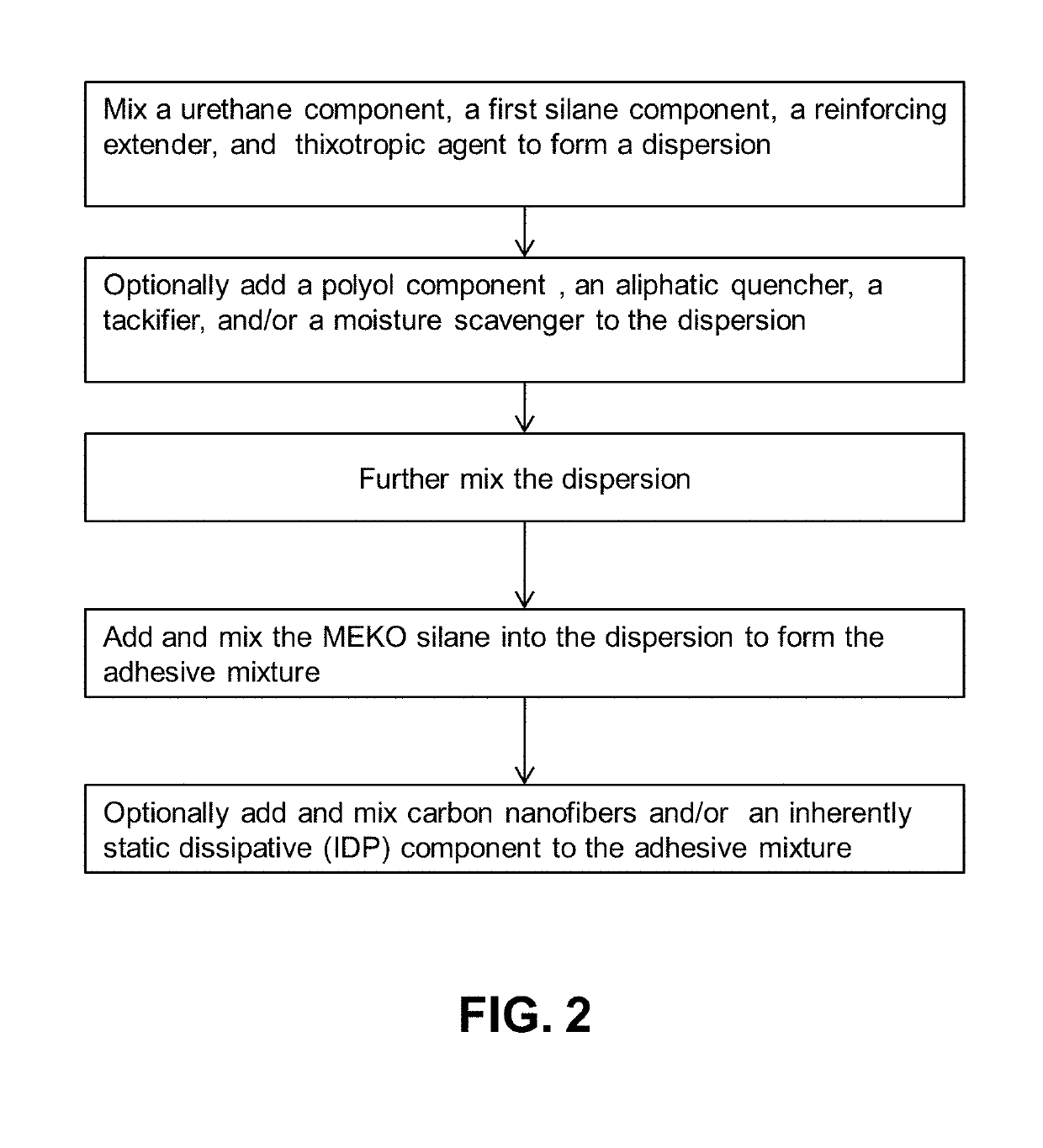

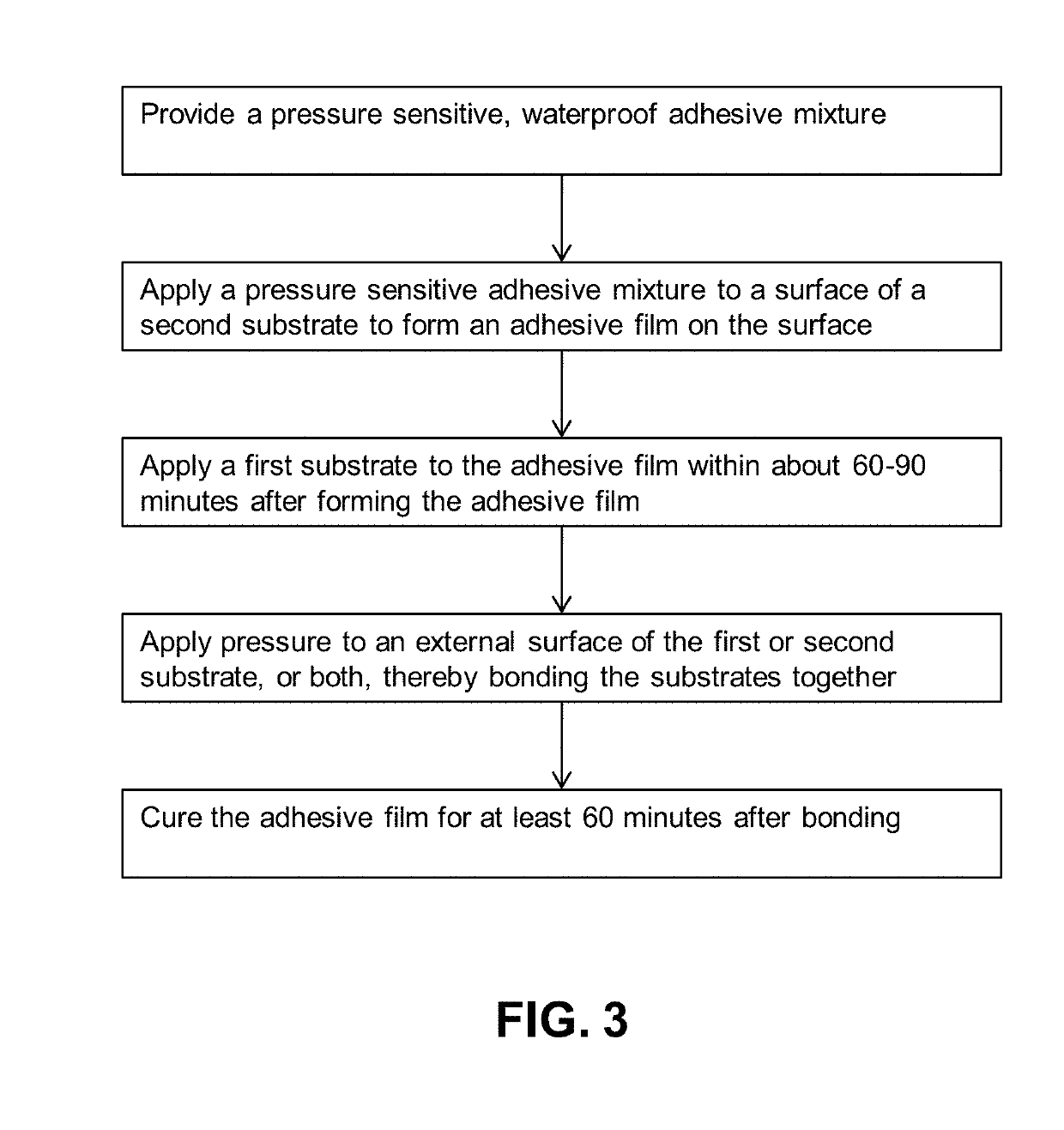

Waterproof urethane-based adhesive compositions are described herein. Silane is reacted with prepolymer urethane to at least partially end-cap the urethane. A reinforcing extender, a thixotropic agent, and methylethylketoximino (MEKO) silane are also added to the composition. When applied to a substrate, the adhesive composition has a tack-free time of at least about 90-120 minutes. The adhesive is cured to a final product that is waterproof, hydrolytically stable, and pH resistant. In conjunction with the adhesive, a prepolymer composition may be used to suppress moisture vapor emanating from a concrete surface. The prepolymer composition can penetrate and polymerize within the near-surface region of the concrete substrate to form a densified concrete / plastic matrix that is self-priming when cured. This reaction reduces the porosity of the concrete surface, thereby restricting moisture vapor emissions as well as blocking negative hydrolytic effects of elevated concrete pH / moisture from acting on the adhesive or topically applied coatings.

Owner:DICKENS CARROLL BENFORD

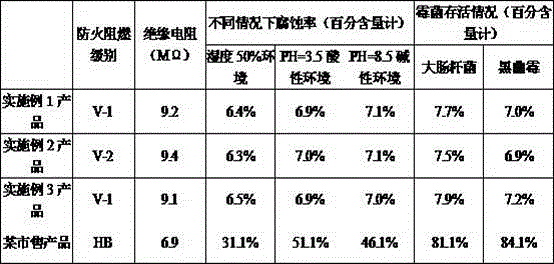

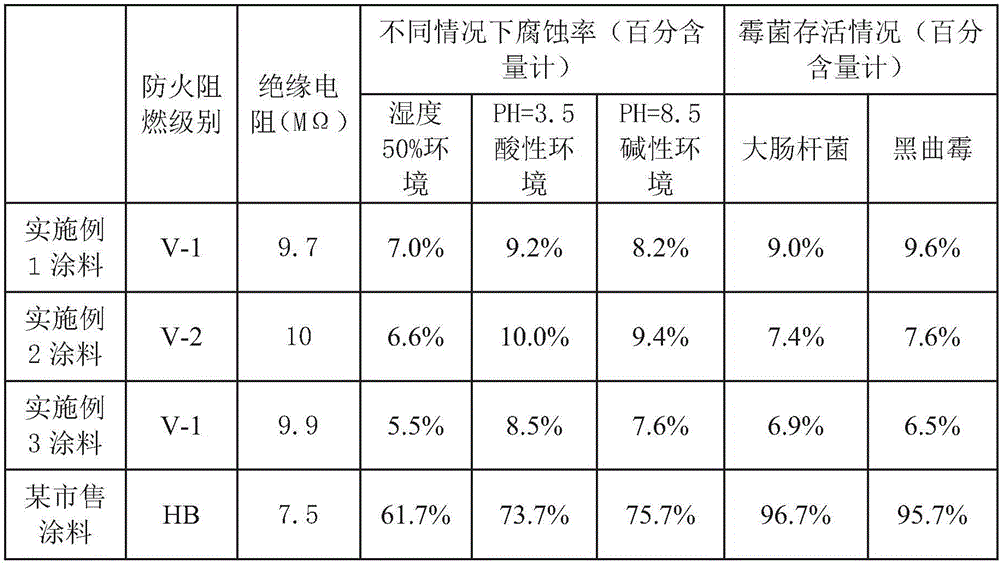

Environment-friendly and antibacterial polypropylene plastic-wood composite board for buildings

InactiveCN105936699AExcellent antibacterial and mildew resistanceExtended service lifeAcrylic resinPolypropylene

The invention discloses an environment-friendly and antibacterial polypropylene plastic-wood composite board for buildings. The composite board is made from the following components by weight: 60-80 parts of polypropylene, 60-79 parts of rice straw powder, 40-50 parts of acrylic resin, 8-10 parts of caustic soda, 20-30 parts of urea, 12-18 parts of ammonium hydroxide, 5-9 parts of an acrylonitrile-butadiene styrene copolymer, 4-8 parts of calcium stearate, 2-5 parts of methyl ethyl ketoxime, and 4-8 parts of molybdenum dithiocarbamate. Compared with ordinary plastic sheets, the environment-friendly and antibacterial polypropylene plastic-wood composite board provided by the invention has more excellent antibacterial and anti-mildew performance, does not mildews or rots during use, has longer service life, and can be widely used in decoration, municipal gardens, docks and other occasions.

Owner:ZHEJIANG QIAO XING CONSTR GRP HUZHOU INTELLIGENT SCI & TECH

UV (Ultra Violet) curable coating good in adhesion and high in curing speed and preparation method thereof

ActiveCN103834276AGood dispersionImprove flame retardant performancePolyester coatingsPolyesterDispersity

The invention discloses a UV (Ultra Violet) curable coating good in adhesion and high in curing speed. The UV curable coating is characterized by being prepared from the following raw materials in parts by weight: 50-55 parts of polyester acrylate, 9-11 parts of trimethylolpropane triacrylate, 7-9 parts of tripropylene glycol diacrylate, 4-5 parts of 2-hydroxyl-2-methyl-1-phenyl-1-acetone, 10-13 parts of ethoxylated trimethylolpropane triacrylate, 3-5 parts of xylene, 2-4 parts of methyl ethyl ketoxime, 1-2 parts of polydimethylsiloxane, 1-2 parts of freshwater mussel shell meal, 5-7 parts of nano zinc oxide, 4-6 parts of kaoline and 4-5 parts of auxiliaries. The UV curable coating is added with the nano zinc oxide, the coating is improved in dispersity and has excellent flame retardant efficiency and antibacterial effect; due to the added auxiliaries, the UV curable coating is good in leveling property, even in coating film and high in curing speed, and has excellent chemical resistance and low temperature resistance, and the coating film formed is high in adhesion to substrates difficult to stick, such as plastics.

Owner:江门市新会区常仕化工有限公司

Packing bag made of crop stalk finished product

A packing bag made of a crop stalk finished product relates to the technical field of biomass material processing and production, and is characterized by being prepared from the following materials by weight: 11 parts of epoxidized natural rubber, 1 parts of calcium molybdate, 3 parts of stearic acid, 1.5 parts of isobornyl acrylate, 6.5 parts of triethyl citrate, 1 part of ethyl methyl ketone oxime, 7 parts of hydroxy-propyl acrylate, 4 parts of barite powder, 4 parts of bisphenol A epoxy acrylate, 7 parts of polyethylene resin, 2 parts of grape-kernel oil, 6 parts of nano-wollastonite, 2 parts of triethyl citrate I, 1 part of ammonium chloride, 1 part of sodium silicate, 4 parts of high abrasion resistant carbon black, 1 part of sulfur, 3 parts of magnesium hydroxide, and 10 parts of a blending additive. The packing bag is reasonable in preparation method, convenient in operation, water-proof and insect-proof.

Owner:FUNAN SHENGTIAN NEW ENERGY DEV CO LTD

Outdoor high wear resistant PVC plastic-wood composite board for buildings

The invention discloses an outdoor high wear resistant PVC plastic-wood composite board for buildings. The composite board is made of the following components by weight: 80-90 parts of PVC, 60-79 parts of rice straw powder, 20-25 parts of PS, 5-8 parts of trimethylolpropane triacrylate, 3-7 parts of sorbitol, 6-11 parts of phenol, 2-5 parts of formaldehyde, 4-8 parts of caustic soda, 5-9 parts of an acrylonitrile-butadiene styrene copolymer, 4-8 parts of calcium stearate, 2-5 parts of methylethylketoxime, and 4-8 parts of molybdenum dithiocarbamate. The outdoor high wear resistant PVC plastic-wood composite board provided by the invention ahs the advantages of high strength, good plasticity, wear resistance, low cost, strong corrosion resistance and the like, is encironment-friendly, and can be widely used in building decoration, door and window frames, furniture manufacturing and other fields.

Owner:HUZHOU ZHONGCHEN CONSTR

Ultraviolet curing coating capable of being used on surfaces of plastic and stone and preparation method thereof

ActiveCN103834279AImprove aging resistanceEvenly dispersedEpoxy resin coatingsPolyester coatingsNeopentylglycol diacrylateKetone

The invention discloses an ultraviolet curing coating capable of being used on surfaces of plastic and stone. The ultraviolet curing coating capable of being used on the surfaces of plastic and stone is characterized by being prepared from the following raw materials in parts by weight: 20-25 parts of bisphenol A epoxy acrylate, 30-35 parts of polyester acrylate, 10-12 parts of hydroxyethyl acrylate, 6-9 parts of hydroxyethyl methylacrylate, 3-5 parts of photoinitator 2959, 10-13 parts of neopentyl glycol dicarylate, 9-11 parts of cresyl glycidyl ether, 1-2 parts of sodium hexametaphosphate, 1-2 parts of methyl ethyl ketone, 3-5 parts of titanium dioxide, 1-2 parts of grape seed oil, 4-6 parts of barite powder and 4-5 parts of auxiliary agent. The ultraviolet curing coating capable of being used on the surfaces of the plastic and stone is added with a natural antioxidant ingredient of grape seed oil, the anti-aging property of the ultraviolet curing coating can be enhanced, and the ultraviolet curing coating is safe and non-toxic; an auxiliary agent is added, so that the ultraviolet curing coating is uniformly dispersed, the curing speed is high, a film can be rapidly formed, the surface hardness of the film is high, the glossiness is good, the hiding power is high, the film is uniform, and the ultraviolet curing coating has good adhesion property and can be rapidly adhered on the surfaces of plastic and stone.

Owner:佛山市海而斯涂料有限公司

Multifunctional lubricating oil annexing agent

InactiveCN106566599AExcellent flame retardantGood acid and alkali resistanceAdditivesPolychlorinated biphenylPhosphate

The invention relates to a multifunctional lubricating oil annexing agent. The multifunctional lubricating oil annexing agent is composed of the following components including a styrene-butadiene-styrene segmented copolymer, polyacrylate rubber, o-cresol formaldehyde epoxy resin, fatty acid sodium, single lauryl alcohol phosphate acid ester, balm essential oil, chenopodium ambrosioides oil, 2-ethylhexyl epoxystearate, benzalkonium chloride, dichloro isocyanuric acid sodium, piperine, prochloraz, ammonium bicarbonate, nanometer aluminum powder, activated calcium carbonate, zinc isoocatanoate, nanometer activated calcium carbonate, paraffin, spodumene powder, molybdenum disilicide powder, polychlorinated biphenyl, decabrominated dipheny ethane, hexahydro-phthalic anhydride, sodium antimonite powder, fluoboric acid, fumaric acid, pentaerythritol triarylate, methyl ethyl ketoxime, dibutyltin dilaurate and sodium hexametaphosphate. The multifunctional lubricating oil annexing agent has the excellent inflaming retarding performance, acid-base resistance, anti-mildew performance and anti-microbial performance, and the product performance is improved.

Owner:安陆市万众创新智能科技有限公司

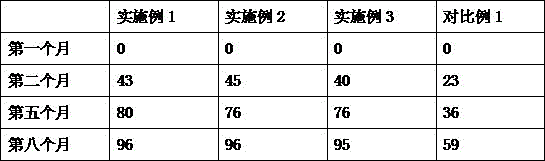

Environment-friendly packaging bag and preparation method thereof

The invention discloses an environment-friendly packaging bag and a preparation method thereof. The environment-friendly packaging bag is prepared from, by weight, 10-60 parts of polyethylene, 40-100 parts of starch, 20-80 parts of reed pulp, 70-80 parts of aluminum oxide, 10-50 parts of zircon sand, 20-100 parts of methyl ethyl ketoxime, 30-90 parts of blanc fixe, 20-50 parts of bisphenol A epoxy acrylate and 10-80 parts of fibrous brucite. The preparation method of the environment-friendly packaging bag includes the steps that polyethylene, starch, reed pulp, aluminum oxide, zircon sand, methyl ethyl ketone, blanc fixe, bisphenol A epoxy acrylate and fibrous brucite are mixed to be uniform through a high-speed mixer, wherein the mixing time ranges from 60 min to 100 min, and the rotating speed ranges from 300 r / min to 350 r / min; then the mixture is subjected to blow molding through a blow molding machine. After the environment-friendly packaging bag is buried in soil for eight months, the degradation rate reaches up to 96%, and it is shown that the packaging bag can be completely degraded basically.

Owner:SUZHOU DINGLI PACKAGING

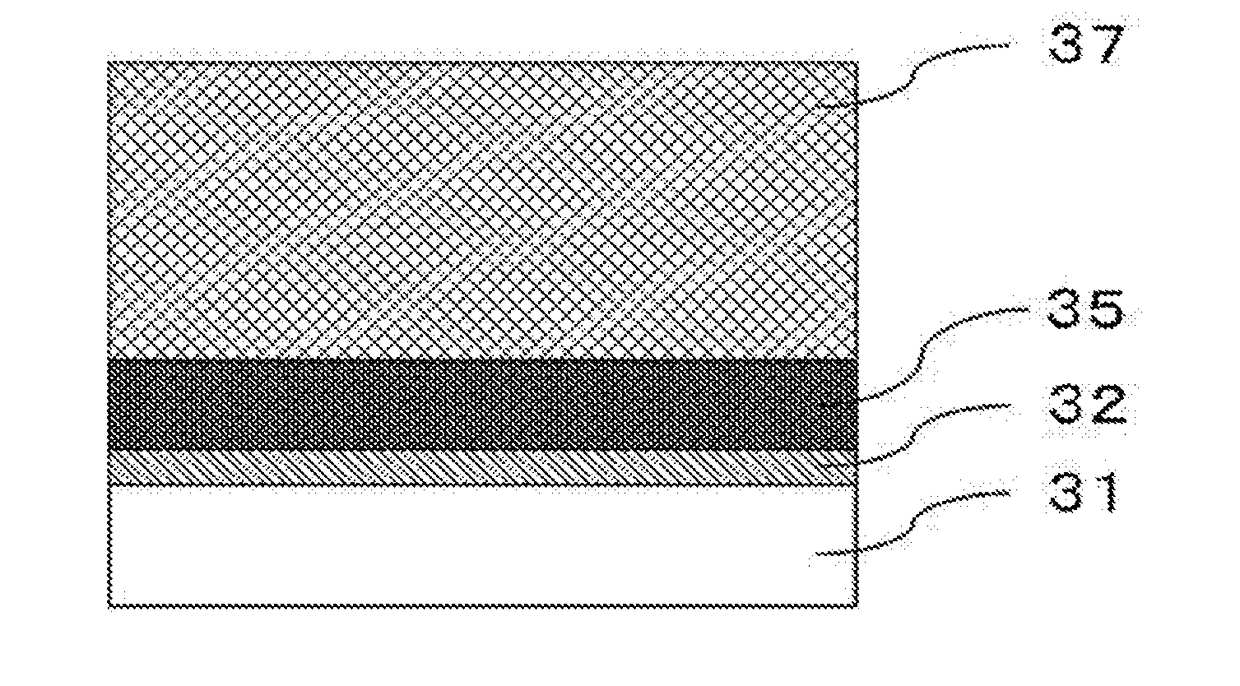

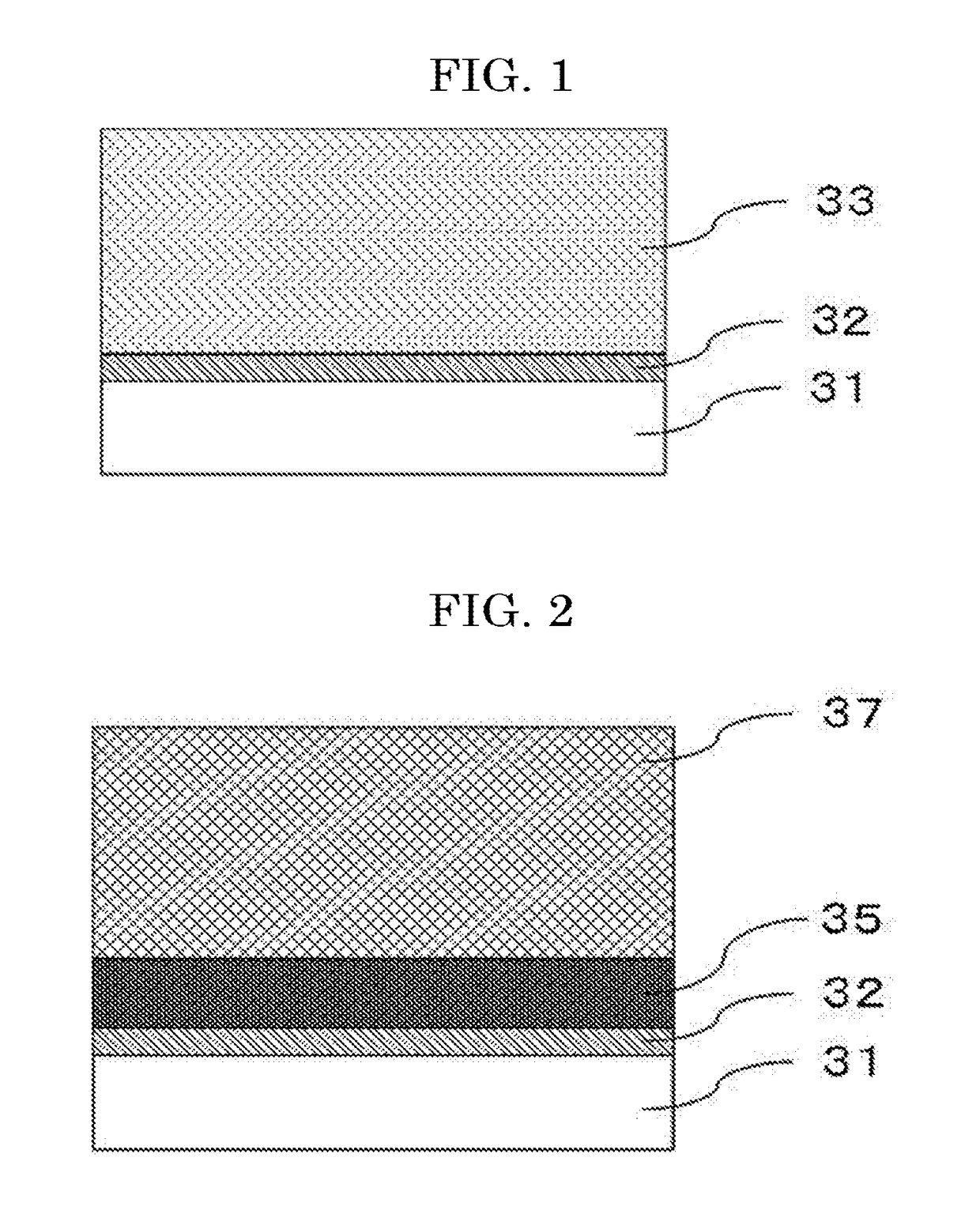

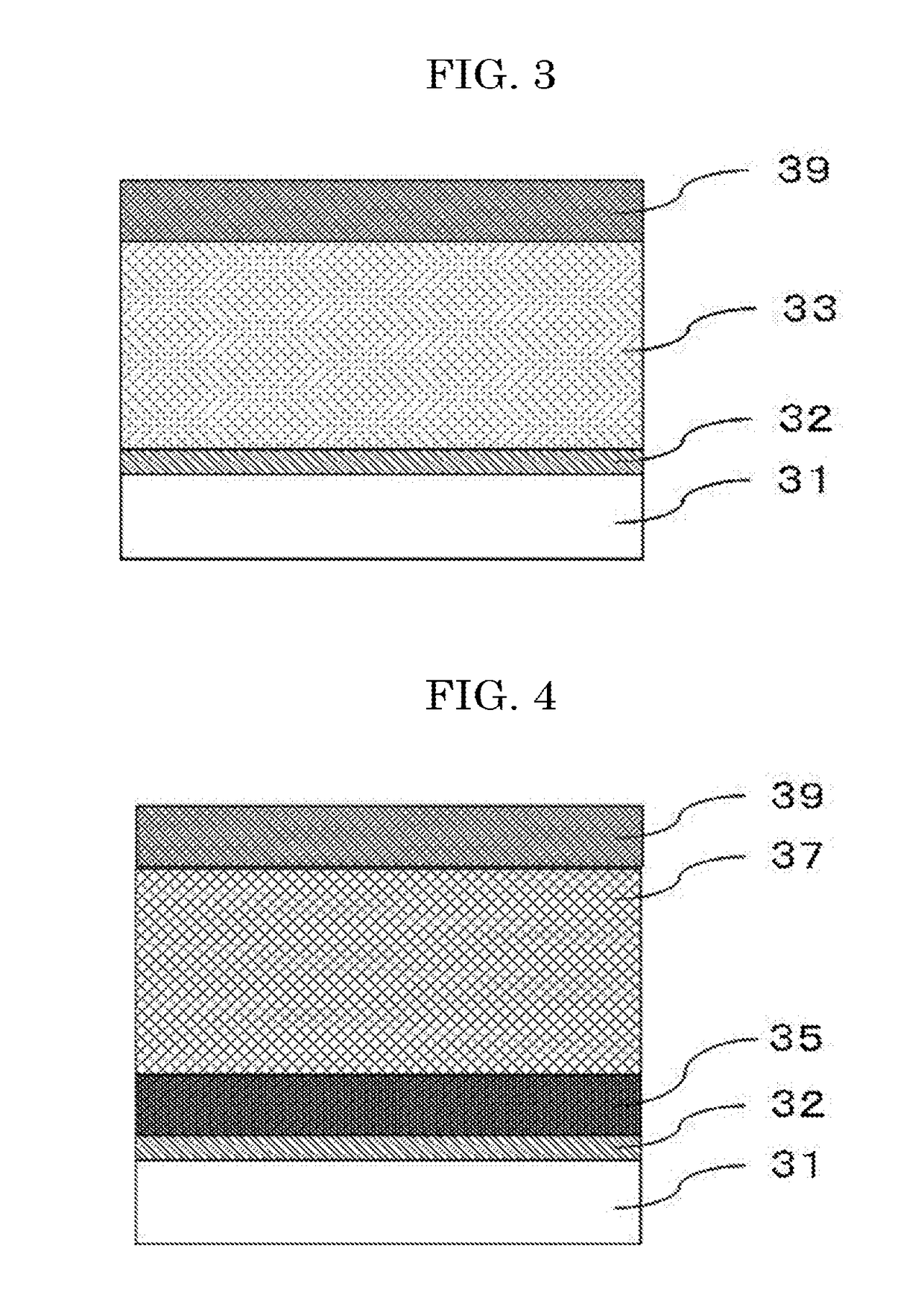

Electrophotographic photoconductor, image forming apparatus, and process cartridge

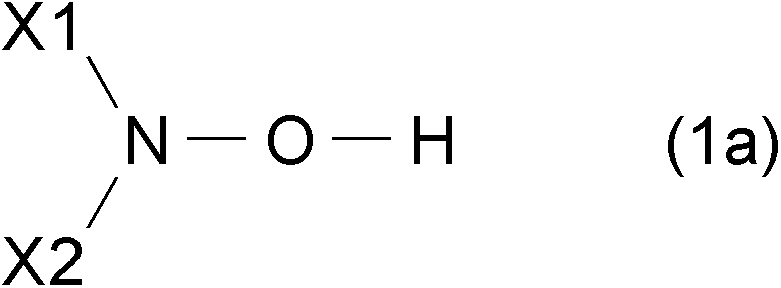

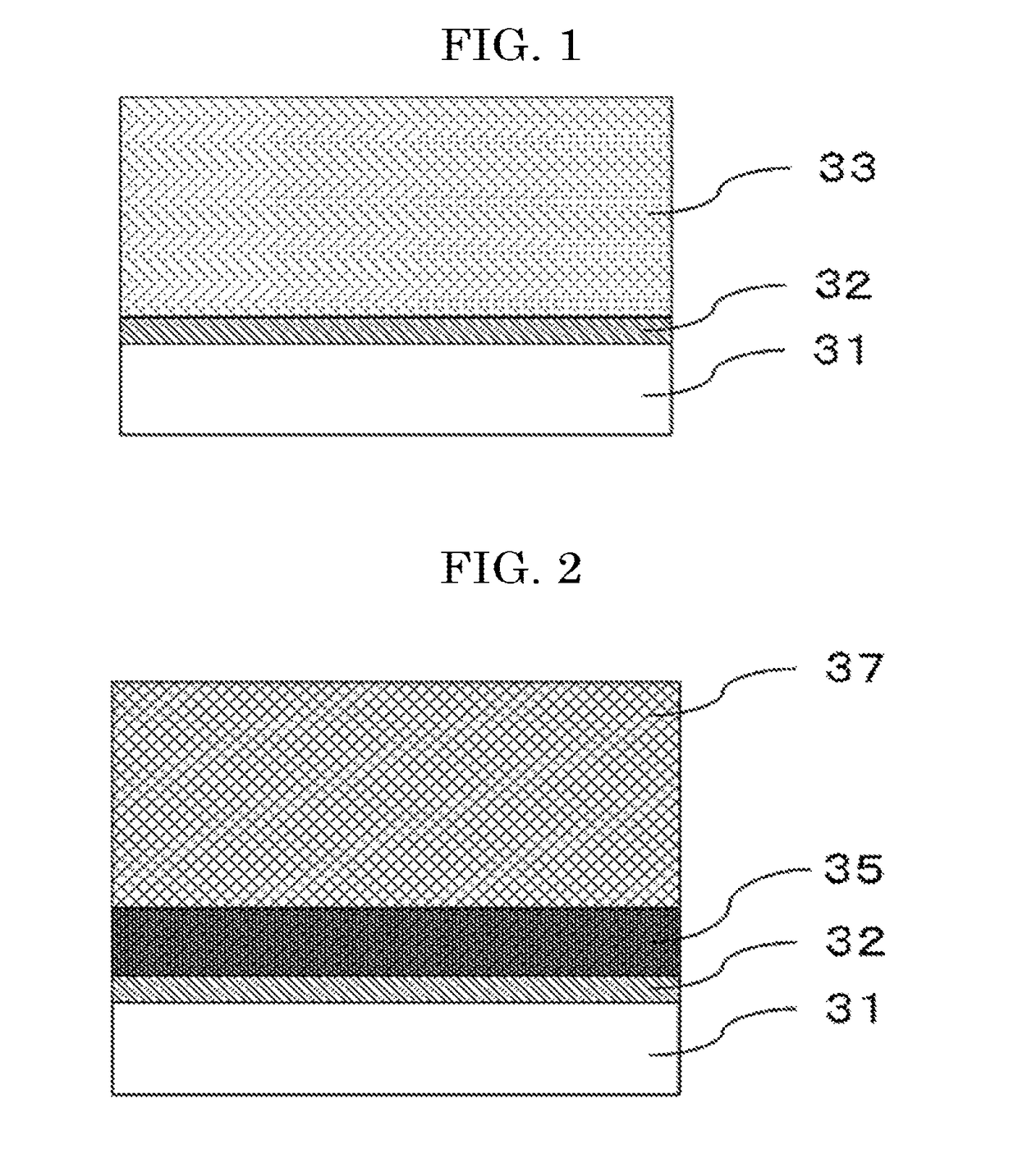

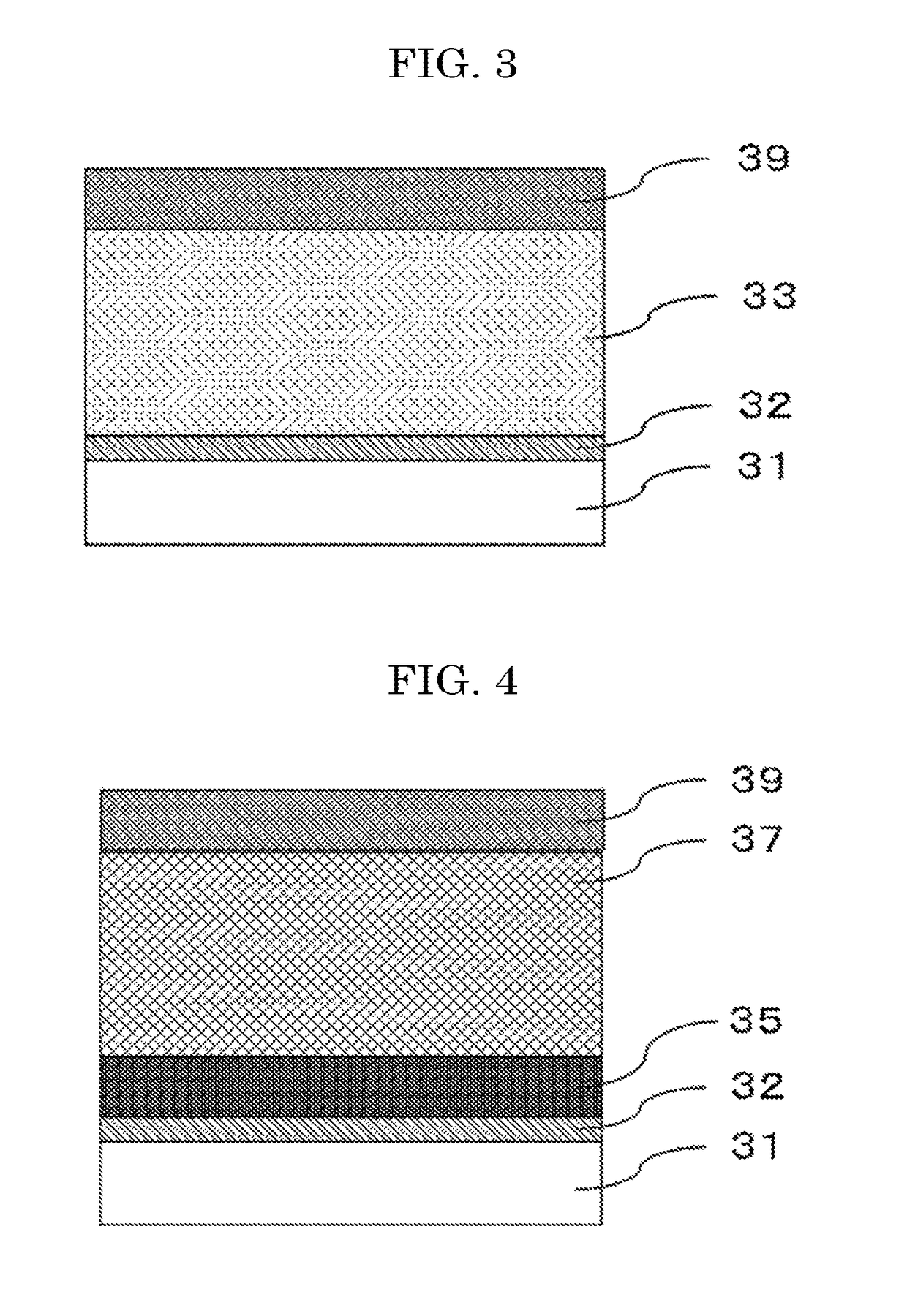

An electrophotographic photoconductor including a support, an undercoat layer, and a photoconductive layer, the undercoat layer and the photoconductive layer being disposed on the support in an order mentioned, wherein the undercoat layer includes zinc oxide particles, a urethane bond-containing resin, and methylethyl ketone oxime, and the undercoat layer satisfies a formula below:10<M / L<400 (Formula)where M is a ratio (ppm) of the methylethyl ketone oxime included in the undercoat layer, and L is an average thickness (μm) of the undercoat layer.

Owner:RICOH KK

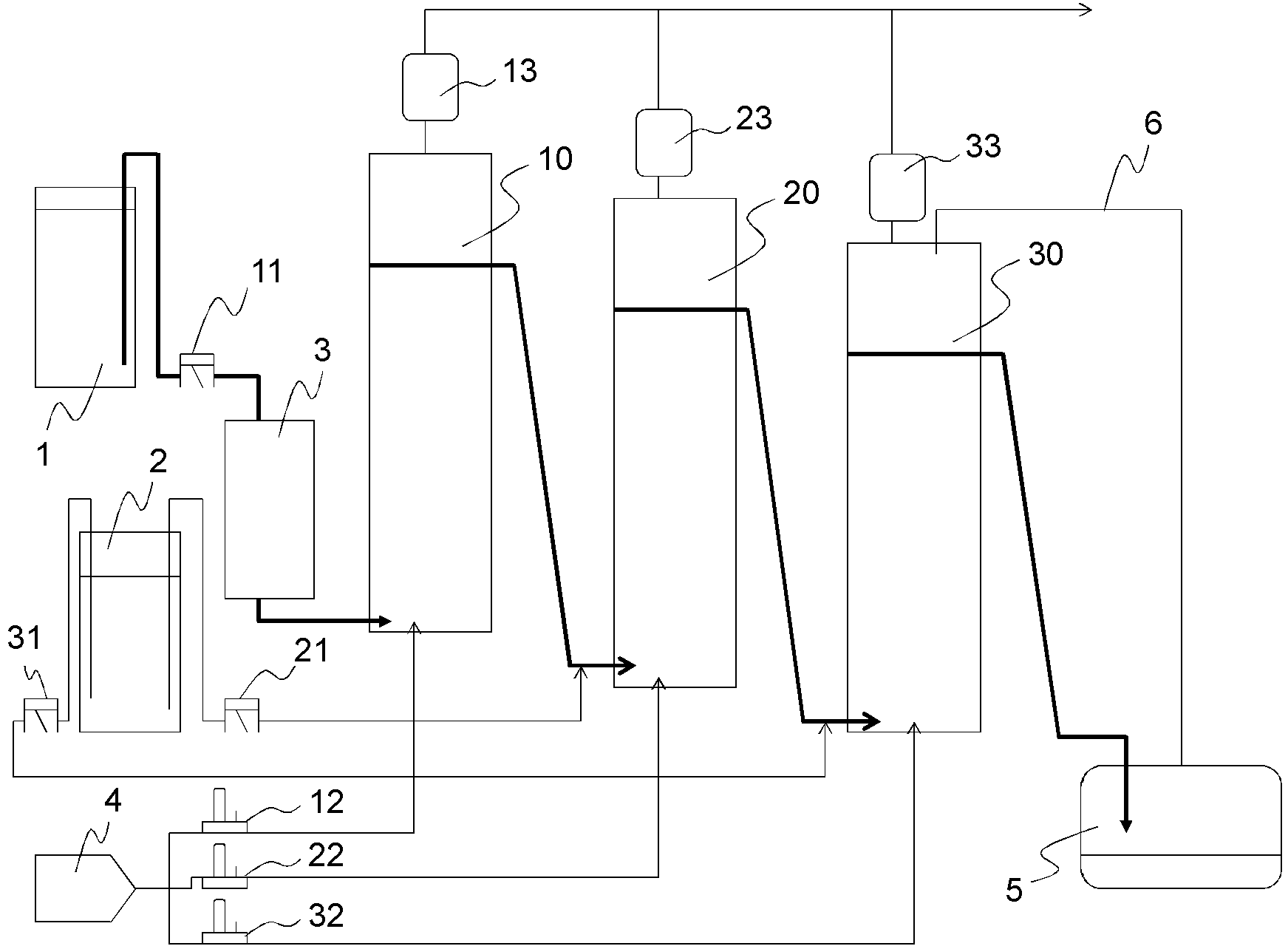

Oxidation catalyst for hydrocarbon compound, and method and apparatus for producing oxide of hydrocarbon compound using same

InactiveCN103140286AControl decompositionPreparation by oxidation reactionsOrganic compound preparationPhosphoric Acid EstersPtru catalyst

According to the first embodiment of the present invention, an oxide of a hydrocarbon compound can be produced with high yield and high productivity by oxidizing the hydrocarbon compound with molecular oxygen in the co-presence of an N-hydroxy compound, such as methyl ethyl ketone or N-hydroxysuccinimide, and a phosphate ester, such as dibutyl phosphate. According to another embodiment of the present invention, an oxide of a hydrocarbon compound can be produced with high yield by using an oxidation catalyst that comprises an oxime compound, such as methyl ethyl ketone. According to another embodiment of the present invention, an alcohol and / or a ketone can be produced with high yield by oxidizing the hydrocarbon compound at a temperature of 160 DEG C. or less, and by decomposing the resulting hydroperoxide, for example, in a unit having an inner surface formed by a material from which no transition metal ion is generated.

Owner:UBE IND LTD

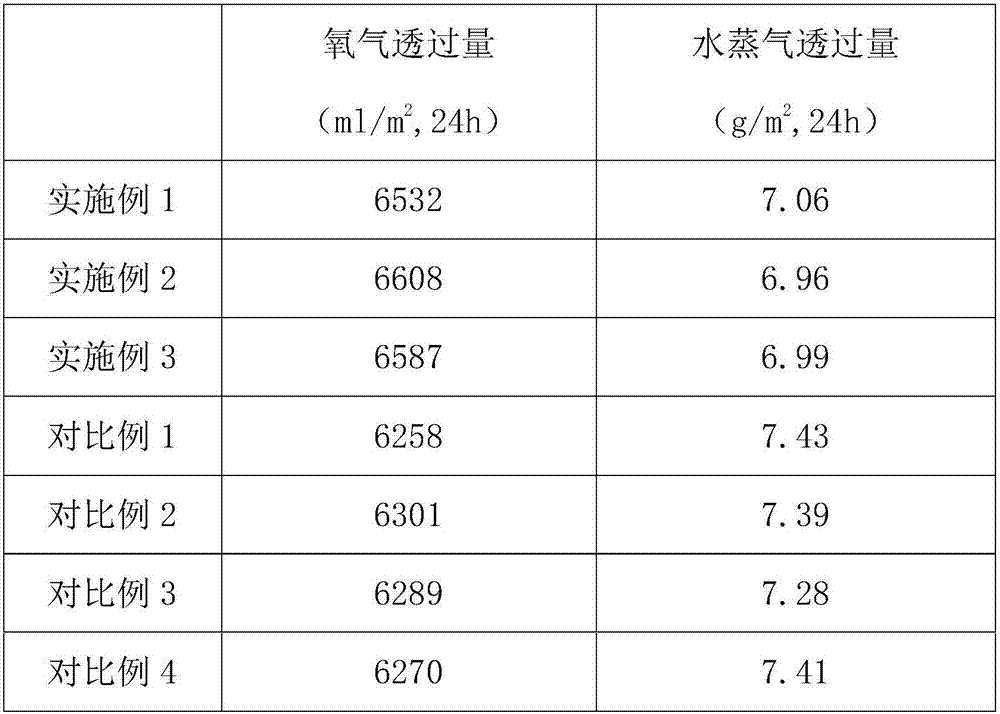

Preparation method and application of air-permeable and waterproof packaging material

The invention discloses a preparation method and application of an air-permeable and waterproof packaging material. The method comprises the following steps: heating ethylene-methylacrylate, polyisocyanate, maleic anhydride grafted polypropylene, poly(butylene adipate-co-terephthalate) and polyethylene glycol in a water bath; centrifuging and washing, and drying to obtain a first mixture; then after ultrasonically dispersing montmorillonite, epichlorohydrin resin and de-ionized water, adding dicyclohexylaminenitrite and methyl ethyl ketoxime; reacting and washing to prepare a second mixture; finally, adding the first mixture and the second mixture into a plasticizer, hydrogenated castor oil and dimethicone and mixing; extruding a mixture through a double-screw extruder, and carrying out die pressing and molding to obtain the finished-product packaging material. The air-permeable and waterproof packaging material prepared by the preparation method has a good ventilation effect and a strong waterproof property and has a good application prospect in medical equipment product packaging.

Owner:叶芳

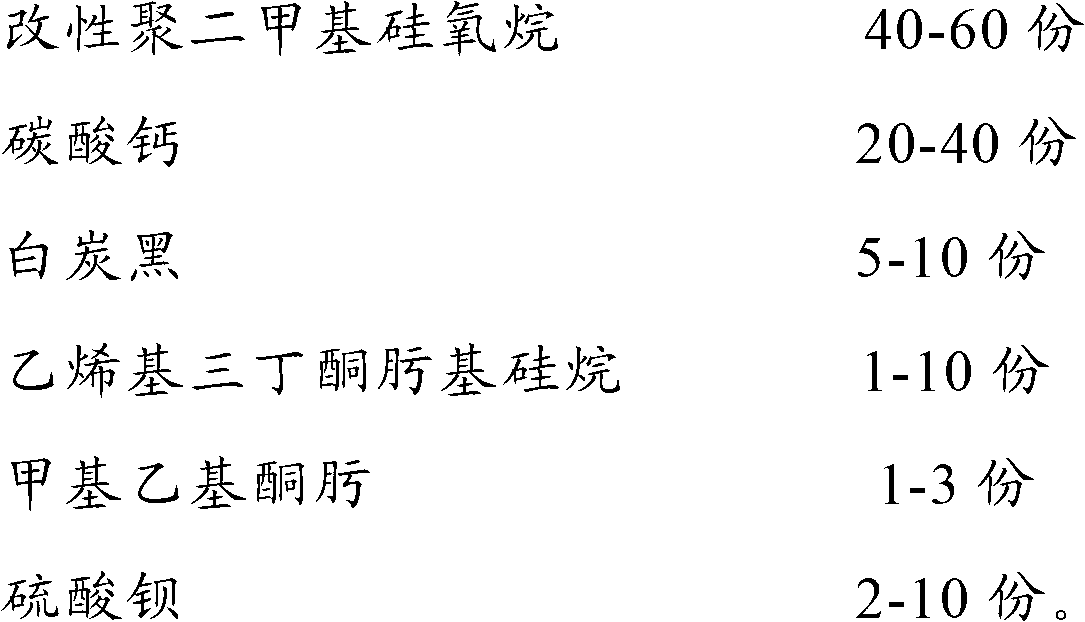

Silicone rubber sealant and preparation method thereof

ActiveCN102796489ABest instant sealHigh initial pressure tightnessNon-macromolecular adhesive additivesOther chemical processesPolymer scienceEthyl group

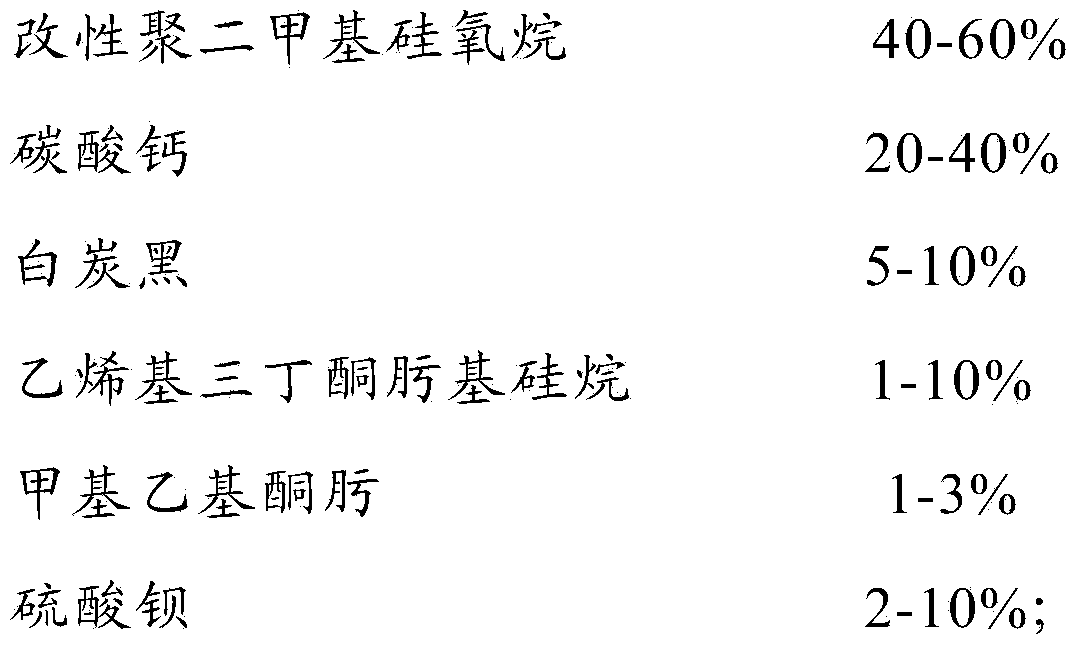

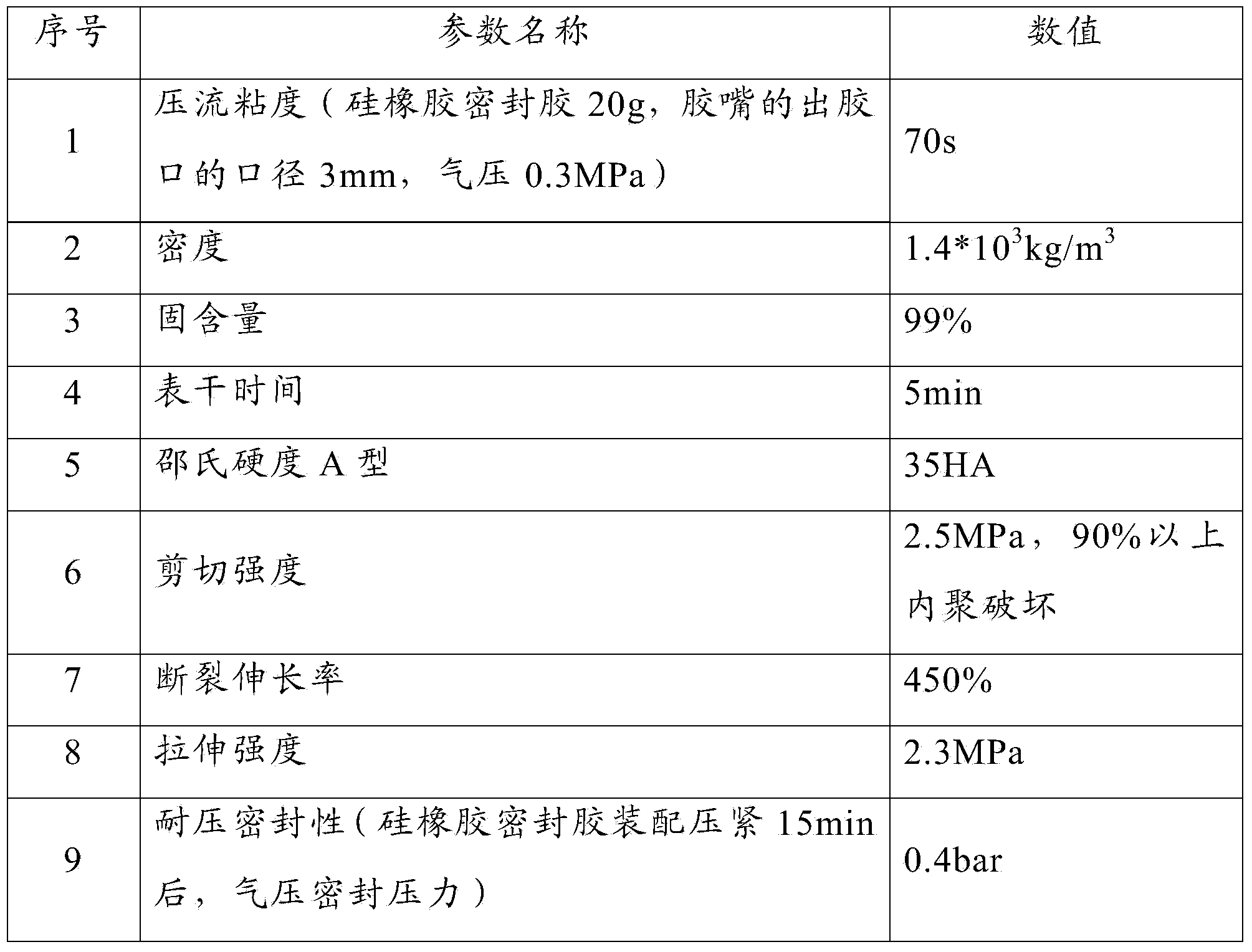

A silicone rubber sealant comprises the following components, by weight: 40-60 parts of modified polydimethylsiloxane, 20-40 parts of calcium carbonate, 5-10 parts of white carbon black, 1-10 parts of vinyltris (methylethylketoxime) silane, 1-3 parts of ethyl methyl ketone oxime and 2-10 parts of barium sulfate. The invention also provides a preparation method for the silicone rubber sealant. The silicone rubber sealant of the invention has relatively good instant sealing performance.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

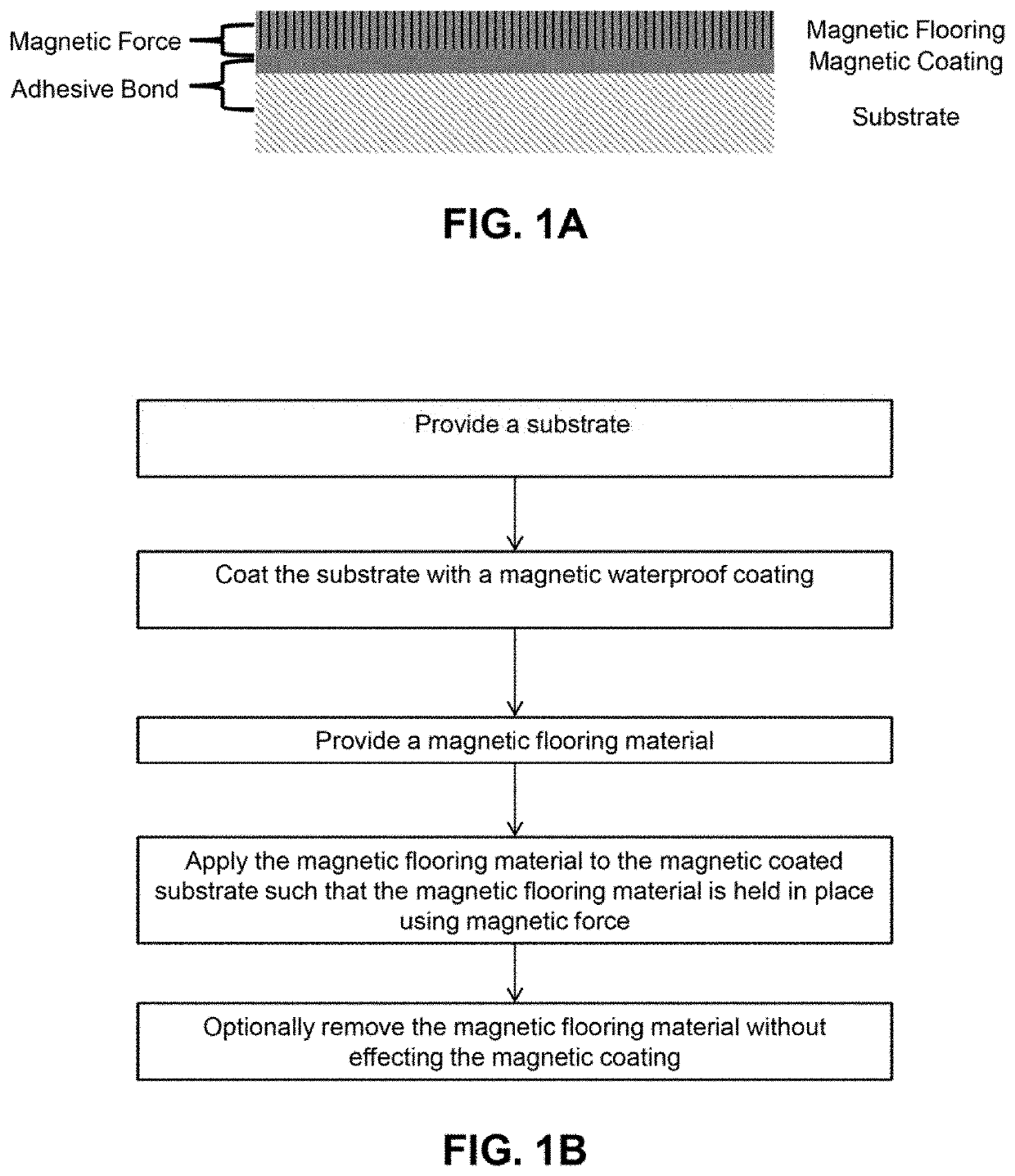

Magnetic waterproof coating compositions

InactiveUS20200248030A1Many timesSuppresses cure ratePolyureas/polyurethane adhesivesInorganic material magnetismEndcappingPolymer science

Magnetic waterproof urethane-based coating compositions are described herein. Silane is reacted with prepolymer urethane to at least partially end-cap the urethane. A reinforcing extender, a thixotropic agent, a magnetic agent, and methylethylketoximino (MEKO) silane are also added to the composition. When applied to a substrate, the coating composition has a tack-free time of at least about 90-120 minutes. The coating is cured to a final product that is magnetic, waterproof, hydrolytically stable, and pH resistant.

Owner:DICKENS CARROLL BENFORD

Weather resistant matte silicone coating special for emas and preparation method thereof

A weather resistant matte silicone coating special for EMAS, comprising: 80˜130 parts by weight of α,ω-dihydroxypolydimethylsiloxane; 0.5˜10 parts by weight of a linear polydimethylsiloxane with terminal hydroxyl group; 1˜10 parts by weight of fumed silica; 10˜50 parts by weight of precipitated silica; 1˜5 parts by weight of color masterbatch; 0.9˜5 parts by weight of organotin chelate catalyst; crosslinking agent, comprising 1.5˜7 parts by weight of methyltri(methylethylketoximino)silane, 1.5˜7 parts by weight of vinyltri(methylethylketoximino)silane, and 1˜7 parts by weight of aminopropyltriethoxysilane; 1.5˜6 parts by weight of delustering agent; and 250˜350 parts by weight of a solvent. The coating has the properties of low viscosity, high flow, relatively fast curing, moderate strength, good adhesion, good mattness, being environmentally friendly and the like.

Owner:CHENGDU TALY TECH CO LTD +1

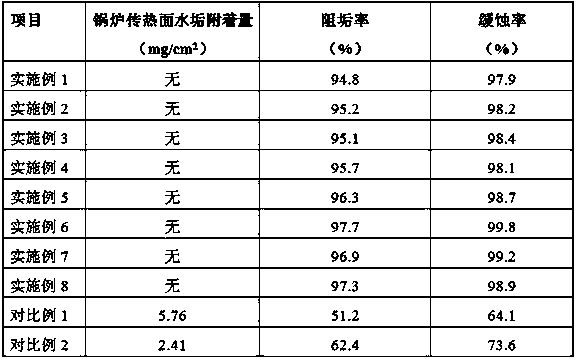

Efficient deoxidizing agent for boiler feed water and preparation method and application of efficient deoxidizing agent

PendingCN109928447AToxic solutionSolve the pollution of the environmentWater/sewage treatment by degassingGas phaseTetramethyl-p-phenylenediamine

The invention relates to an efficient deoxidizing agent for boiler feed water and a preparation method and application of the efficient deoxidizing agent. The efficient deoxidizing agent is prepared from the raw materials in percentage by weight: 8-15% of organic amine modified lignin, 10-18% of erythorbic acid, 2-4% of polyepoxysuccinic acid, 1-3% of polyaspartic acid, 4-6% of a pH regulator,0.4-0.8% of tetramethyl p-phenylene diamine, 0.2-0.4% of carbohydrazide, 0.1-0.4% of methyl ethyl ketoxime, and the balance of water. The deoxidizing agent can be used for water treatment for a steam boiler, a hot water boiler, a heating system and a water feeding pipeline. Compared with the prior art, the organic amine modified lignin and the erythorbic acid are jointly used as a deoxidant, the organic amine modified lignin has the effect of adsorbing oxygen and can reduce dissolved oxygen in water and assist the erythorbic acid to form a protective oxide layer on the metal surface, at differenttemperatures of boiler water, the concentration of a deoxidizing agent system in the gas phase / liquid phase can be balanced, the oxygen-removing corrosion inhibition effect is improved, and the corrosion problem of boilers, pipelines and heat exchangers is solved.

Owner:汇科琪(天津)水质添加剂有限公司

Pressure sensitive, waterproof adhesive compositions

ActiveUS10308847B1Efficient productionAdhesive processesPolyureas/polyurethane adhesivesCarbamatePrepolymer

Pressure sensitive and waterproof urethane-based adhesive compositions and methods of preparing said compositions. A silane is added to a prepolymer urethane to react with the urethane and at least partially end-cap the urethane. A reinforcing extender and a thixotropic agent are added to the composition. Methylethylketoximino (MEKO) silane is further added to the composition. When applied to a substrate, the adhesive composition has a tack-free time of at least about 90-120 minutes. The adhesive is cured to a final product that is waterproof, hydrolytically stable, and pH resistant.

Owner:DICKENS CARROLL BENFORD

Indoor deodorizing coating

The invention discloses an indoor deodorizing coating. The indoor deodorizing coating is prepared with urea resin, deodorants, emulsifying agents, antioxidants, antifoaming agents, dispersing agents and anti-skinning agents. The deodorants are anion additives. The emulsifying agents are sodium alkyl benzene sulfonate. The antioxidants are pentaerythritol. The antifoaming agents are polydimethyl siloxane. The dispersing agents are N,N-ethylene bis-stearamide. The anti-skinning agents are methyl ethyl ketone oxime. The indoor deodorizing coating is prepared with the urea resin, the deodorants, the emulsifying agents, the antioxidants, the antifoaming agents, the dispersing agents and the anti-skinning agents, so the prepared indoor deodorizing coating has the special effects of purifying odors in the air and removing toxicity in the air, and is resistant to ageing, stable in quality and long in storage time.

Owner:江苏博腾新材料股份有限公司

Waterproof air-permeable packaging film material and preparation method thereof

The invention discloses a waterproof air-permeable packaging film material and a preparation method thereof. The waterproof air-permeable packaging film material is prepared by using a phenolic resin, water-soluble glucan, polyvinyl alcohol and tributyl citrate as the main components and adding polypropylene glycol adipate, vaseline, coix seed oil, zeolite powder, potassium tetraborate, dehydroacetic acid, lanthanum oxide, polyethylene wax powder, methyl ethyl ketone oxime, a plasticizer and a coupling agent. The preparation method comprises the following steps: thermostatic water bath treatment, centrifugal separation, vacuum drying, grinding refinement, microwave treatment, compounding, plasticizing, melt extrusion, hot pressing and the like. The waterproof air-permeable packaging film material has the advantages of excellent waterproofness, excellent air permeability and high physical strength, can satisfy the industrial requirements, and has favorable application prospects.

Owner:苏州缔绿电子科技有限公司

Seal gum for vehicles and preparation method of seal gum

ActiveCN104059594AHigh instant pressure tightnessNon-macromolecular adhesive additivesOther chemical processesHexamethylenetetramineGlycerol

The invention relates to seal gum for vehicles and a preparation method of the seal gum. The seal gum comprises polysulfide rubber, carbon black, dibutyl phthalate, manganese dioxide, diphenylguanidine, epoxy resin, polyethylene polyamine, hexamethylenetetramine, novolac epoxy resin, glycerol triacetate, calcium carbonate, vinyltris(methylethylketoximino)silane, methyl ethyl ketoxime, barium sulfate, silica sol, a phosphate flame retardant, dipentaerythritol, diatomite and a solvent. The preparation method comprises the following steps: adding the polysulfide rubber, dibutyl phthalate and the epoxy resin into the solvent and stirring; adding vinyltris(methylethylketoximino)silane, methyl ethyl ketoxime, barium sulfate, silica sol and the phosphate flame retardant and stirring; adding manganese dioxide, diphenylguanidine, the epoxy resin, polyethylene polyamine, hexamethylenetetramine and the novolac epoxy resin and stirring; adding the rest components and stirring to be uniform to obtain the seal gum. The seal gum is relatively good in instant pressure-resistant seal property and can be applied to a fast-paced production and preparation process.

Owner:上海汉司实业有限公司

Antiseepage paint

InactiveCN104403444APrevent pollution, resurgence, etc.Increase stickinessCoatingsPlasticizerPolyvinyl alcohol

The invention discloses an antiseepage paint which is composed of a film forming material, a plasticizer, a thickener, a defoaming agent, an anti-skinning agent and an anti-cratering agent, wherein the film forming material is polyvinyl alcohol, the plasticizer is diethyl phthalate, the thickener is zinc stearate, the defoaming agent is phenethyl alcohol oleate, the anti-skinning agent is methyl ethyl ketone oxime, and the anti-cratering agent is polydimethylsiloxane. The product, which is prepared from the film forming material, plasticizer, thickener, defoaming agent, anti-skinning agent and anti-cratering agent, has the advantages of favorable viscosity, low shedding tendency and long service life, and can effectively prevent the phenomena of pollution, remoistening and the like on the wall surface.

Owner:SUZHOU AOLAX BUILDING MATERIALS

Weather resistant matte silicone coating and preparation method thereof

A weather resistant matte silicone coating special for EMAS, comprising: 80˜130 parts by weight of α,ω-dihydroxypolydimethylsiloxane; 0.5˜10 parts by weight of a linear polydimethylsiloxane with terminal hydroxyl group; 1˜10 parts by weight of fumed silica; 10˜50 parts by weight of precipitated silica; 1˜5 parts by weight of color masterbatch; 0.9˜5 parts by weight of organotin chelate catalyst; crosslinking agent, comprising 1.5˜7 parts by weight of methyltri(methylethylketoximino)silane, 1.5˜7 parts by weight of vinyltri(methylethylketoximino)silane, and 1˜7 parts by weight of aminopropyltriethoxysilane; 1.5˜6 parts by weight of delustering agent; and 250˜350 parts by weight of a solvent. The coating has the properties of low viscosity, high flow, relatively fast curing, moderate strength, good adhesion, good mattness, being environmentally friendly and the like.

Owner:CHENGDU TALY TECH CO LTD +1

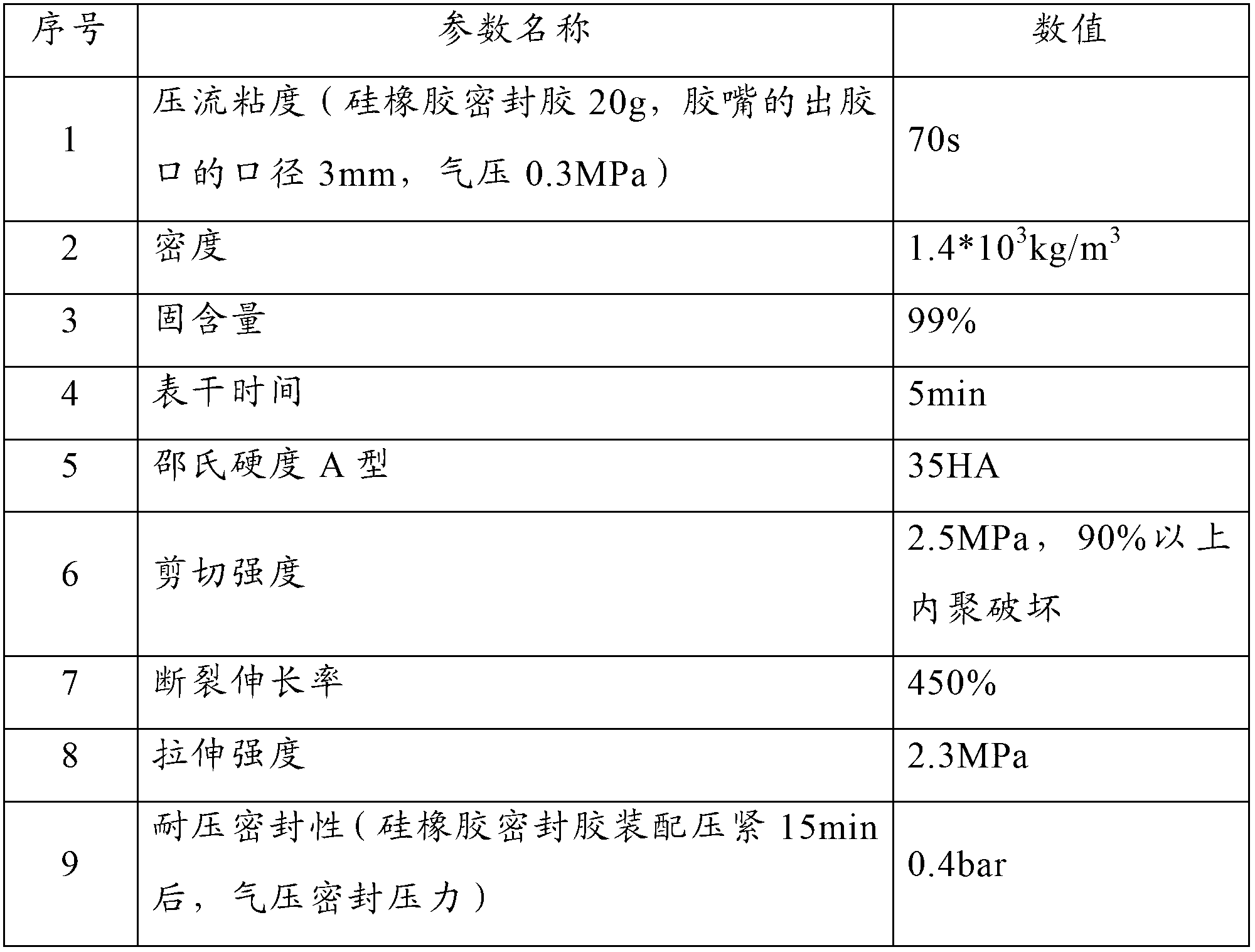

Sealant for equipment installation of water conservancy and hydropower engineering

InactiveCN106118580AThe preparation process is simpleSimple processing methodNon-macromolecular adhesive additivesOil/fat/wax adhesivesTriethylphosphiteSuccinic acid

The invention relates to a sealant for installation of water conservancy and hydropower engineering equipment, which consists of the following components: iron oxide powder, chromium oxide powder, manganese oxide powder, calcium chloride, sodium carbonate, silicon powder, trimethoxysilane, titanium dioxide, Methyl ethyl ketone oxime, bismaleimide resin, sodium lauryl sulfate, polyarylether nitrile, starch octenyl succinate, ethylene bis stearic acid amide, barium sulfate, triethylene glycol di Isooctanoate, epoxy novolac resin, polyamide, dioctyl sebacate, triethyl phosphite, dimethylethanolamine, aluminum silicate, sodium hydroxymethylcellulose, imidacloprid, polyoxyethylene ether, glass Fiber, Castor Oil. The product of the invention has good pressure flow viscosity, Shore hardness, shear strength, elongation at break, and tensile strength, and has high pressure-resistant sealing performance and excellent performance, thereby improving product performance.

Owner:孟根森

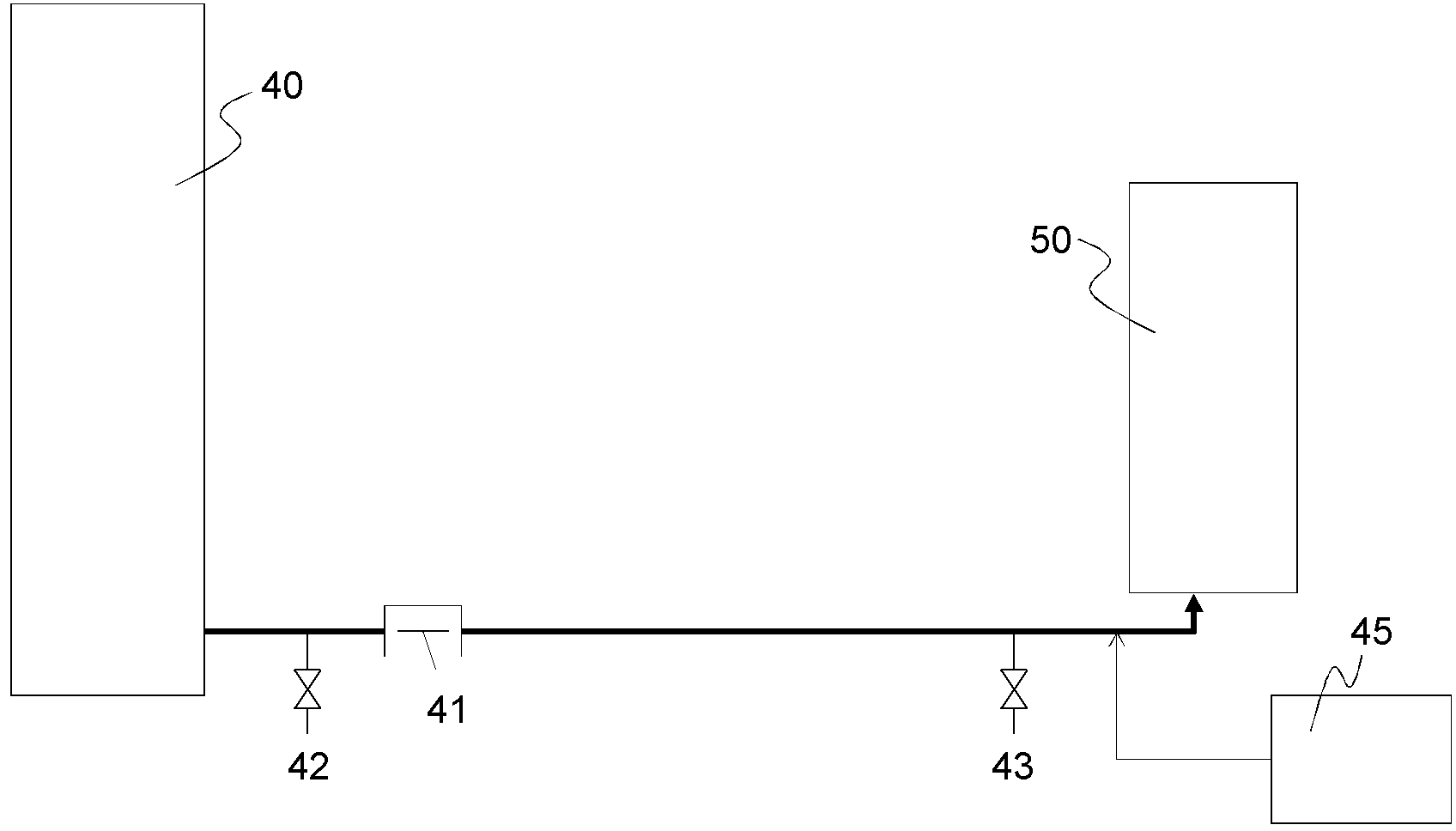

Anti-seepage coating and preparation process thereof

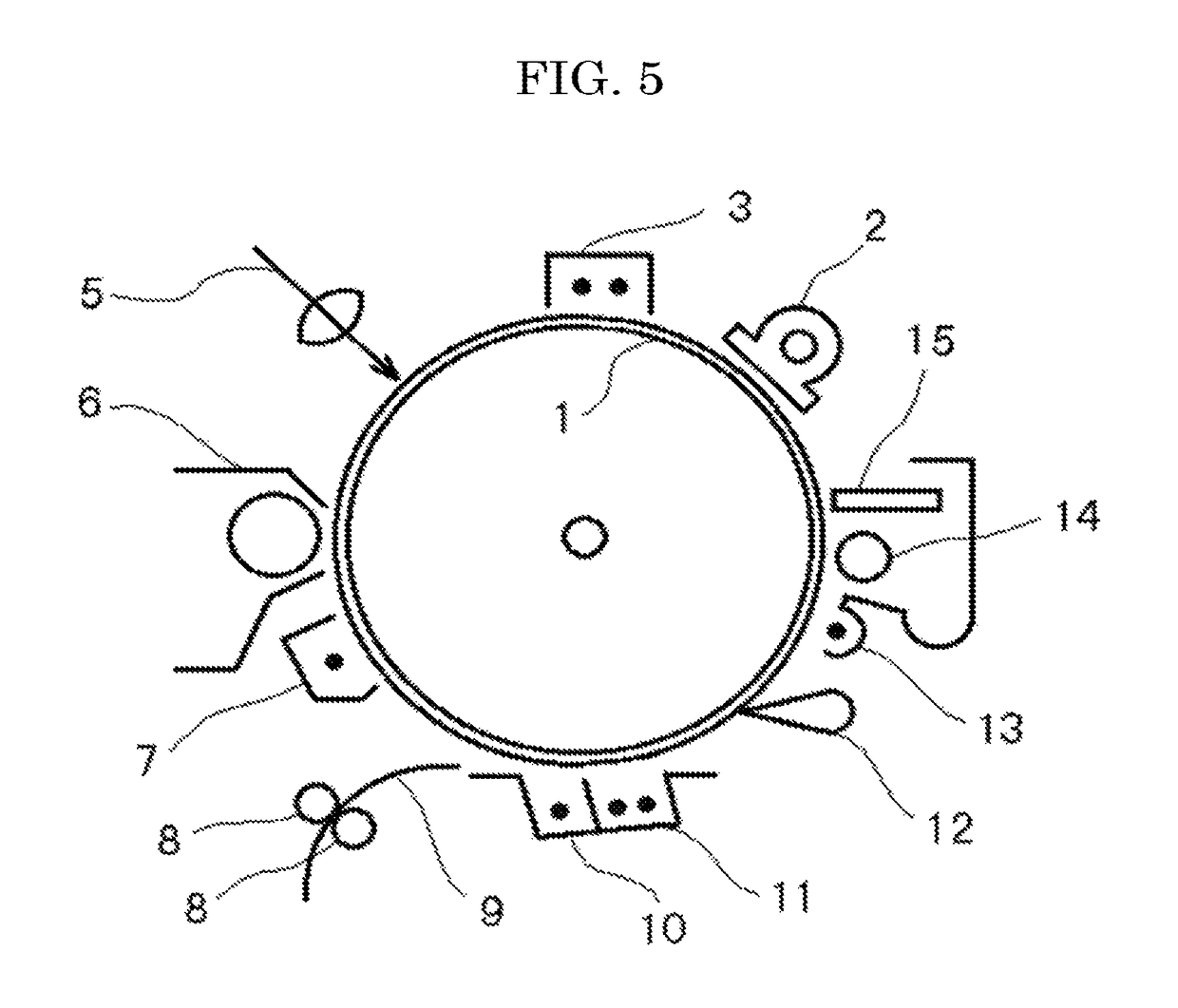

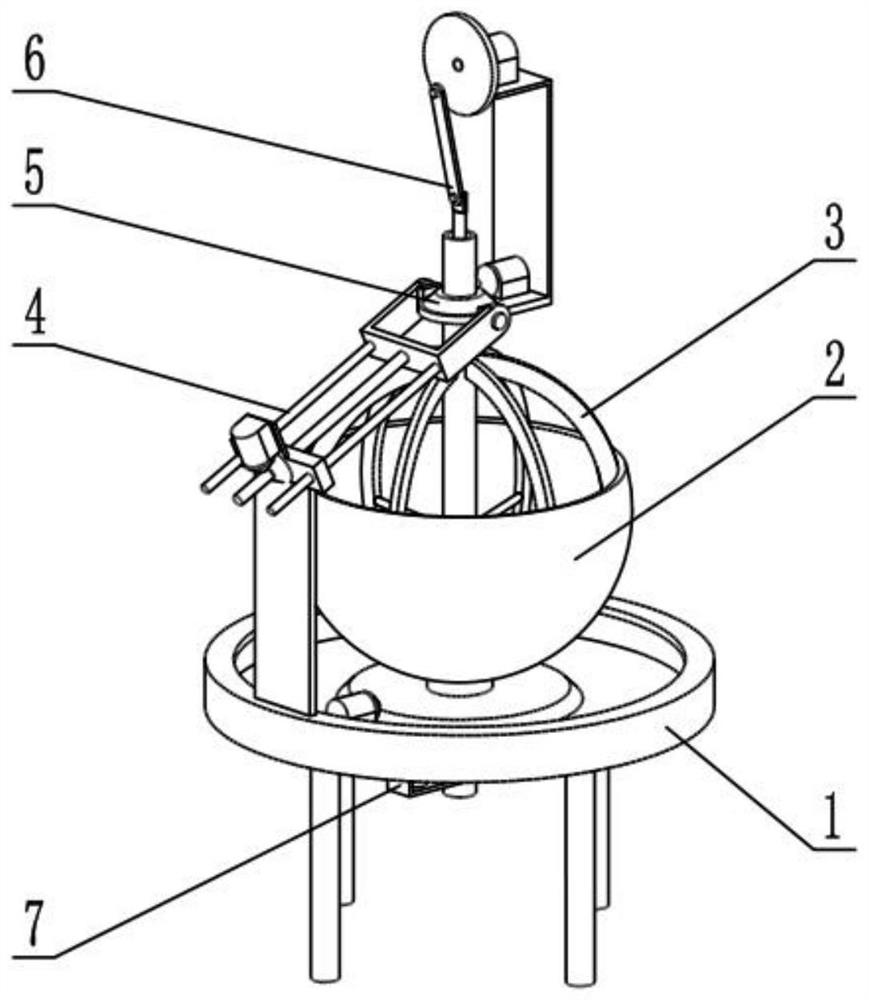

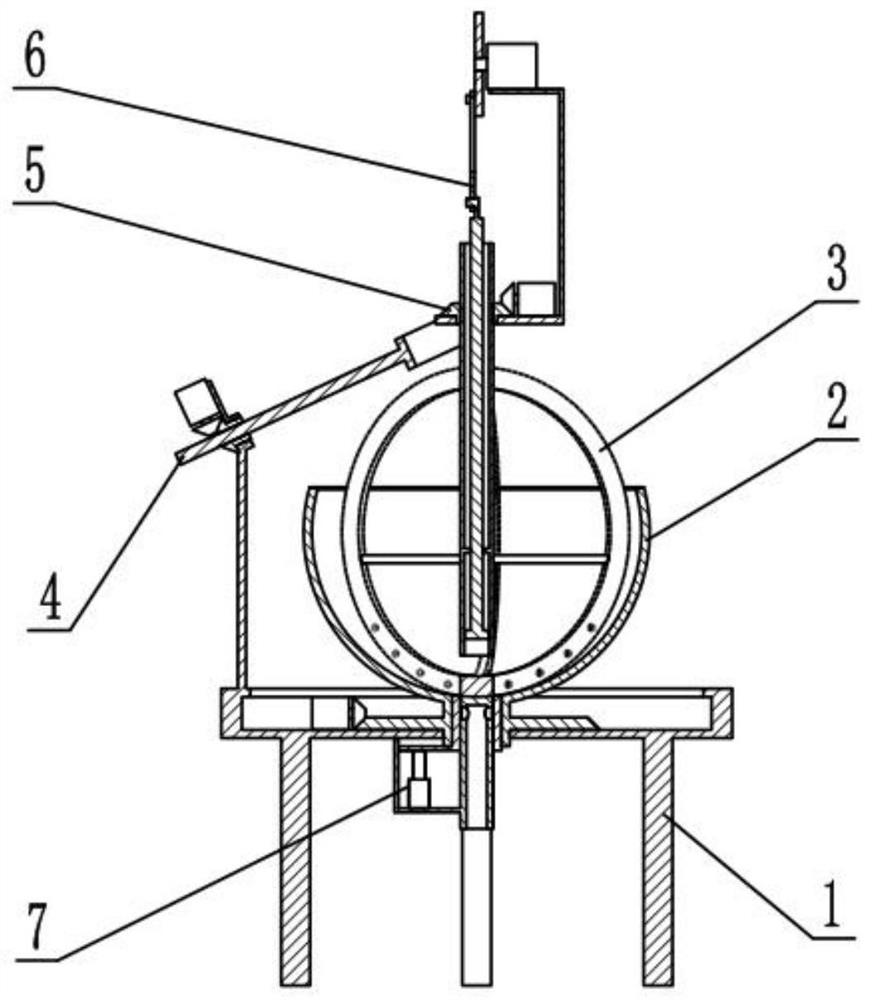

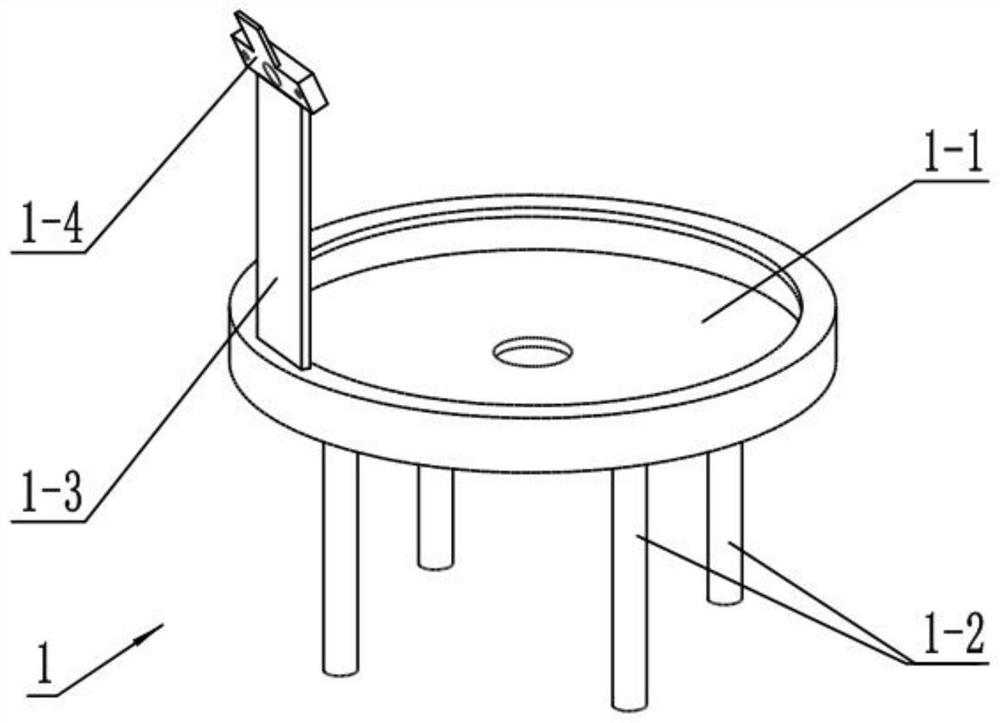

InactiveCN112742258AImprove stirring efficiencyEasy to useTransportation and packagingRotary stirring mixersPolyvinyl alcoholEthyl group

The invention relates to the field of coating preparation, in particular to an anti-seepage coating and a preparation technology thereof. The anti-seepage coating is prepared from, by weight, 80 parts of polyvinyl alcohol, 12 parts of diethyl phthalate, 1.5 parts of zinc stearate, 1 part of methyl ethyl ketoxime and 2 parts of polydimethylsiloxane. The preparation process of the anti-seepage coating comprises the following steps:1, weighing and preparing raw materials in proportion; 2, mixing and stirring all the raw materials; and 3, after stirring is completed, packaging and storing the coating. The invention further relates to an anti-seepage coating preparation device in the anti-seepage coating preparation process. The anti-seepage coating preparation device comprises a supporting frame, a mixing box, a stirring mechanism, an angle adjusting mechanism, a stirring power mechanism, a sucking and spraying mechanism and a discharging mechanism.

Owner:王庆华

A kind of UV curing coating with good adhesion and fast curing speed and preparation method thereof

ActiveCN103834276BGood dispersionImprove flame retardant performancePolyester coatingsPolyesterDispersity

The invention discloses a UV (Ultra Violet) curable coating good in adhesion and high in curing speed. The UV curable coating is characterized by being prepared from the following raw materials in parts by weight: 50-55 parts of polyester acrylate, 9-11 parts of trimethylolpropane triacrylate, 7-9 parts of tripropylene glycol diacrylate, 4-5 parts of 2-hydroxyl-2-methyl-1-phenyl-1-acetone, 10-13 parts of ethoxylated trimethylolpropane triacrylate, 3-5 parts of xylene, 2-4 parts of methyl ethyl ketoxime, 1-2 parts of polydimethylsiloxane, 1-2 parts of freshwater mussel shell meal, 5-7 parts of nano zinc oxide, 4-6 parts of kaoline and 4-5 parts of auxiliaries. The UV curable coating is added with the nano zinc oxide, the coating is improved in dispersity and has excellent flame retardant efficiency and antibacterial effect; due to the added auxiliaries, the UV curable coating is good in leveling property, even in coating film and high in curing speed, and has excellent chemical resistance and low temperature resistance, and the coating film formed is high in adhesion to substrates difficult to stick, such as plastics.

Owner:江门市新会区常仕化工有限公司

Silicone rubber sealant and preparation method thereof

ActiveCN102796489BBest instant sealHigh initial pressure tightnessNon-macromolecular adhesive additivesOther chemical processesPolymer scienceSealant

A silicone rubber sealant comprises the following components, by weight: 40-60 parts of modified polydimethylsiloxane, 20-40 parts of calcium carbonate, 5-10 parts of white carbon black, 1-10 parts of vinyltris (methylethylketoxime) silane, 1-3 parts of ethyl methyl ketone oxime and 2-10 parts of barium sulfate. The invention also provides a preparation method for the silicone rubber sealant. The silicone rubber sealant of the invention has relatively good instant sealing performance.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Anti-skinning smooth efficient paint

The invention discloses an anti-skinning smooth efficient paint which is prepared by abietic acid, anti-skinning agents, flatting agents, pigment dispersing agents, antifoaming agents and anti-setting agents. The anti-skinning agents are methyl ethyl ketone oxime. The flatting agents are polydimethylsiloxane. The pigment dispersing agents are sorbitan fatty acid. The antifoaming agents are palm oil and the anti-setting agents are polyamide wax. The anti-skinning smooth efficient paint is prepared by the abietic acid, the anti-skinning agents, the flatting agents, the pigment dispersing agents, the antifoaming agents and the anti-setting agents, and the prepared product is resistant to skinning, smooth in surface, small in tension, stable in quality and long in storage time.

Owner:江苏博腾新材料股份有限公司

Thermosetting composition, paint finishing method and method for producing a painted article

ActiveUS11365326B2Quality improvementImprove securityPolyurea/polyurethane coatingsPolyester coatingsPolymer scienceEthyl group

The present invention relates to a thermosetting composition characterized in that it contains (A) a polyester resin of number average molecular weight 1,000-10,000, hydroxyl value 5-200 mg KOH / g and, (B) 0.5-2.0 equivalents relative to the hydroxyl groups of the aforesaid component (A) of a compound (B) which is a blocked aliphatic isocyanate compound having reactivity with the hydroxyl groups of component (A), wherein the blocking is with methyl ethyl ketoxime and / or ε-caprolactam, (C) 0.05-5 parts by weight of a bismuth compound, per 100 parts by weight of total resin solids of component (A) and component (B), and (D) 0.5-50 parts by weight of an organosilicate represented by the following general formula (I) and / or a condensation product thereof, relative to 100 parts by weight of total resin solids of component (A) and component (B) wherein R1, R2, R3 and R4 in the formula each mean hydrogen atom or 1-10 carbon organic group, and can be the same or different, n is 1. By using the thermosetting, not only does stain resistance appear a short time after painting, but also excellent stain resistance is maintained for a long period, which fulfil the paint film performance requirements for painted steel sheet such as water resistance and bending workability and which have high environmental protection qualities and safety.

Owner:AKZO NOBEL COATINGS INT BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com