Efficient deoxidizing agent for boiler feed water and preparation method and application of efficient deoxidizing agent

A technology of boiler feed water and deoxidizer, which is applied in the field of industrial water treatment, can solve the problems of general deoxygenation slow-release effect, many restrictions on use conditions, and the influence of hydrazine use effect, so as to improve solubility, increase grafting rate, deoxidize Excellent effect of oxygen sustained release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

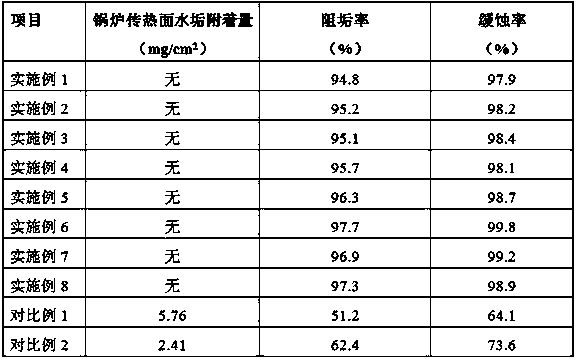

Examples

Embodiment 1

[0038] The high-efficiency deoxidizer for boiler feed water in this example is prepared from raw materials including the following components and weight percentages: 10% organic amine modified lignin, 15% isoascorbic acid, 3% polyepoxysuccinic acid, polyaspartic acid 2% acid, 5% pH regulator, 0.5% tetramethyl-p-phenylenediamine, 0.2% carbazide, 0.3% methyl ethyl ketoxime and the rest is water.

[0039] Wherein, the molecular structural formula of organic amine modified lignin is as shown in formula I:

[0040] (Formula I);

[0041] Among them, Lignin is the remaining structural unit in lignin, and n is 1.

[0042] In this embodiment, the preparation method of organic amine modified lignin comprises the following steps:

[0043] Step (1): Dissolve lignin in alkaline solution, then add alkaline catalyst and organic amine, heat to 40°C, and stir well to obtain a premixed solution;

[0044] Step (2): Keep the temperature of the premixed solution prepared in step (1) at 56°C, ...

Embodiment 2

[0056] The high-efficiency deoxidizer for boiler feed water in this example is prepared from raw materials including the following components and weight percentages: 12% organic amine modified lignin, 14% isoascorbic acid, 4% polyepoxysuccinic acid, polyaspartic acid 3% acid, 5% pH regulator, 0.6% tetramethyl-p-phenylenediamine, 0.3% carbazide, 0.2% methyl ethyl ketoxime, and the rest is water.

[0057] Wherein, the molecular structural formula of organic amine modified lignin is as shown in formula I:

[0058] (Formula I);

[0059] Among them, Lignin is the remaining structural unit in lignin, and n is 1.

[0060] In this embodiment, the preparation method of organic amine modified lignin comprises the following steps:

[0061] Step (1): Dissolve lignin in alkaline solution, then add alkaline catalyst and organic amine, heat to 50°C, and stir well to obtain a premixed solution;

[0062] Step (2): Keep the temperature of the premixed solution prepared in step (1) at 60°C,...

Embodiment 3

[0074] The high-efficiency deoxidizer for boiler feed water in this example is prepared from raw materials including the following components and weight percentages: 8% organic amine modified lignin, 12% isoascorbic acid, 2% polyepoxysuccinic acid, polyaspartic acid Acid 1%, pH regulator 4%, tetramethyl-p-phenylenediamine 0.6%, carbazide 0.4%, methyl ethyl ketoxime 0.2%, and the rest is water.

[0075] Wherein, the molecular structural formula of organic amine modified lignin is as shown in formula I:

[0076] (Formula I);

[0077] Among them, Lignin is the remaining structural unit in lignin, and n is 2.

[0078] In this embodiment, the preparation method of organic amine modified lignin comprises the following steps:

[0079] Step (1): Dissolve lignin in alkaline solution, then add alkaline catalyst and organic amine, heat to 42°C, and stir well to obtain a premix;

[0080] Step (2): Keep the temperature of the premixed solution prepared in step (1) at 58°C, add formald...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com