Catalyst used for isobutane dehydrogenation for preparing isobutylene, and preparation method thereof

A catalyst and isobutane technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problems of low efficiency of dehydrogenation catalysts and achieve production costs Inexpensive, easy to handle, and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

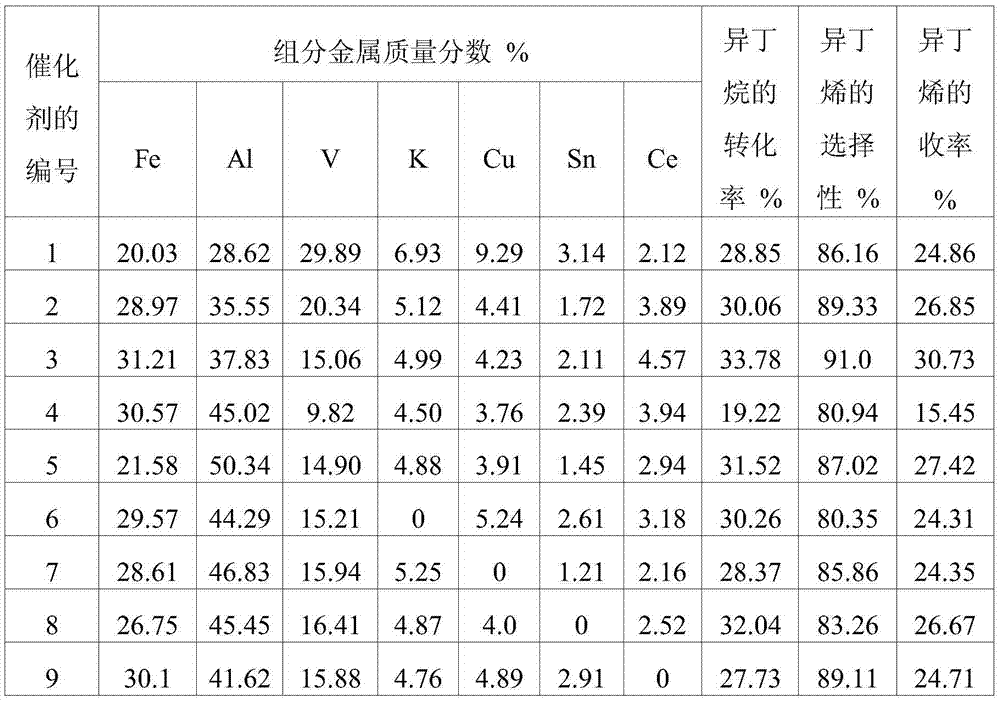

Examples

Embodiment 1

[0043] The present embodiment provides a catalyst for isobutane dehydrogenation, and the preparation method of the catalyst comprises the following steps:

[0044] 1. Dissolve 0.644g ammonium metavanadate in 30mL saturated solution of oxalic acid (density is 1.653g / mL), mix 20.0g ferric nitrate hexahydrate, 45g aluminum nitrate, 0.31g hexahydrate cerium nitrate, 0.429g potassium nitrate, Dissolve 0.302g of copper nitrate trihydrate and 0.176g of tin tetrachloride pentahydrate in 100mL of distilled water, and then mix the two to obtain a mixed system;

[0045] 2. Add ammoniacal liquor (mass concentration is 25%) dropwise to the above-mentioned mixing system under stirring, the dripping rate of ammoniacal liquor is controlled to be 1-20 drops / 10s, and its addition is advisable to make the mixing system form a sol;

[0046] 3. Transfer the sol to an autoclave, keep it at 150°C for 24 hours, then raise the temperature to a pressure of 4MPa, keep it for 30 minutes, release the pres...

Embodiment 2

[0050] The present embodiment provides a catalyst for isobutane dehydrogenation, and the preparation method of the catalyst comprises the following steps:

[0051] 1. Dissolve 0.846g ammonium metavanadate in 30mL saturated solution of oxalic acid, 20.0g ferric nitrate hexahydrate, 45g aluminum nitrate, 0.31g cerium nitrate hexahydrate, 0.429g potassium nitrate, 0.302g copper nitrate trihydrate, 0.176 g tin tetrachloride pentahydrate was dissolved in 100mL of distilled water, and then the two were mixed to obtain a mixed system;

[0052] 2. Add ammoniacal liquor (mass concentration is 30%) dropwise to the mixing system under stirring, the dripping rate of ammoniacal liquor is controlled to be 1-20 drops / 10s, and its addition is advisable to make the mixed system form a sol;

[0053] 3. Transfer the sol to an autoclave, keep it at 140°C for 26 hours, then raise the temperature to a pressure of 4.5MPa, keep it for 25 minutes, release the pressure, and cool to obtain a solid;

[...

Embodiment 3

[0057] The present embodiment provides a catalyst for isobutane dehydrogenation, and the preparation method of the catalyst comprises the following steps:

[0058] 1. Dissolve 1.287g ammonium metavanadate in 30mL saturated solution of oxalic acid, 15.0g ferric nitrate hexahydrate, 45g aluminum nitrate, 0.31g cerium nitrate hexahydrate, 0.429g potassium nitrate, 0.302g copper nitrate trihydrate, 0.176 g tin tetrachloride pentahydrate was dissolved in 100mL of distilled water, and then the two were mixed to form a mixed system;

[0059] 2. Add ammoniacal liquor (mass concentration 20%) dropwise to the mixing system under agitation, the dripping rate of ammoniacal liquor is controlled to be 1-20 drops / 10s, and the amount added is advisable to make the mixed system form a sol;

[0060] 3. Transfer the sol to an autoclave, keep it at 130°C for 28 hours, then raise the temperature to a pressure of 4MPa, keep it for 40 minutes, release the pressure, and cool to obtain a solid;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com